Cu-based catalyst, its preparation process and use thereof

a technology of cu-based catalysts and catalysts, applied in the field of cu-based catalysts, to achieve the effect of high selectivity to acetoin products, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0238]The preparation of the Cu-based catalyst H1 was as follows:

[0239](1-1) 122 g of copper nitrate, 103 g of ytterbium nitrate and 88 g of aluminum nitrate were dissolved in 1 L of deionized water to formulate a solution A1. 16 g of potassium hydroxide and 24 g of potassium bicarbonate were dissolved in 1 L of deionized water to formulate a solution B1. 1 L of deionized water was added to a 5 L beaker, and warmed up and maintained at 75° C., and under a continuous stirring, to the beaker were added dropwisely the solutions A1 and B1, and the pH value was maintained at about 8.0. After the completion of the dropwise addition, the mixture was continuously stirred for 2 hours, then aged by standing for 2 hours, and filtered to produce a precipitate C1.

[0240](1-2) The precipitate C1 was placed at 110° C. and dried for 24 hours, and then calcined at 400° C. for 5 hours. Then a graphite powder as lubricant was added in an amount of 3% by weight of the precipitate. The mixture was shaped...

example 2

[0244]The preparation of the Cu-based catalyst H2 was as follows:

[0245](1) The catalyst H1 prepared in Example 1 was used as the catalyst precursor;

[0246](2) The above catalyst precursor H1 was ground into powder. The powder H1 was added to the straight sample tube of TP-5082-type chemisorption instrument, and warmed up to 100° C. in the nitrogen atmosphere and kept constantly at this temperature. The feeding was switched to a mixed gas of acetoin / nitrogen having an acetoin volumetric fraction of 1% and treated for 48 hours. The reaction system was cooled and removed to produce a catalyst H2.

[0247]By elemental analysis, the catalyst H2 had the CuO content by weight of 40.1%, the Yb2O3 content by weight of 44.0%, the K2O content by weight of 2.6%, the Al2O3 content by weight of 12.1%, and the acetoin content by weight of 1.2%.

[0248]The catalyst H2 was subjected to the following pre-treatment before it was used in the dehydrogenation reaction of dihydric alcohol to prepare the hydroxy...

examples 3-7

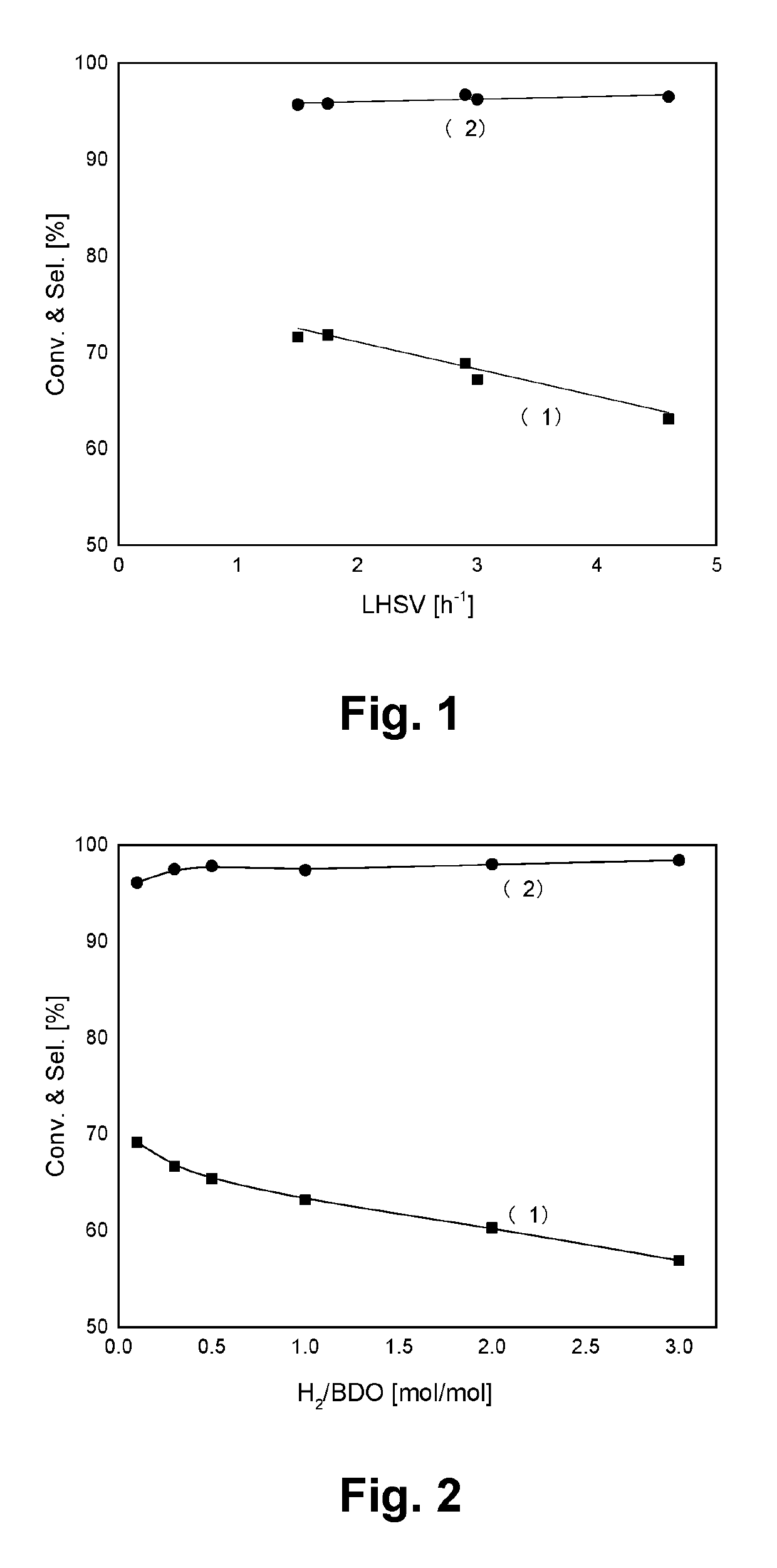

[0251]The pre-reduced catalyst H1 obtained in Example 1 and the pre-treated catalyst H2 obtained in Example 2 were used as catalyst respectively to investigate the reaction performance for the production of acetoin by the direct dehydrogenation of 2,3-butanediol in a fixed bed reactor having an inner diameter of 10 mm. The experiment results were listed in Table 1.

TABLE 1ReactionReactionAcetointemperaturepressureLHSV2,3-butanediolselectivityAcetoinExampleCatalyst(° C.)(MPa)(h−1)Diluentconversion (%)(%)yield (%)3H12300.13No55.669.438.64H22300.13No49.597.148.15H22500.23No67.296.264.76H22700.23No78.893.974.07H23000.013No79.293.173.7

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com