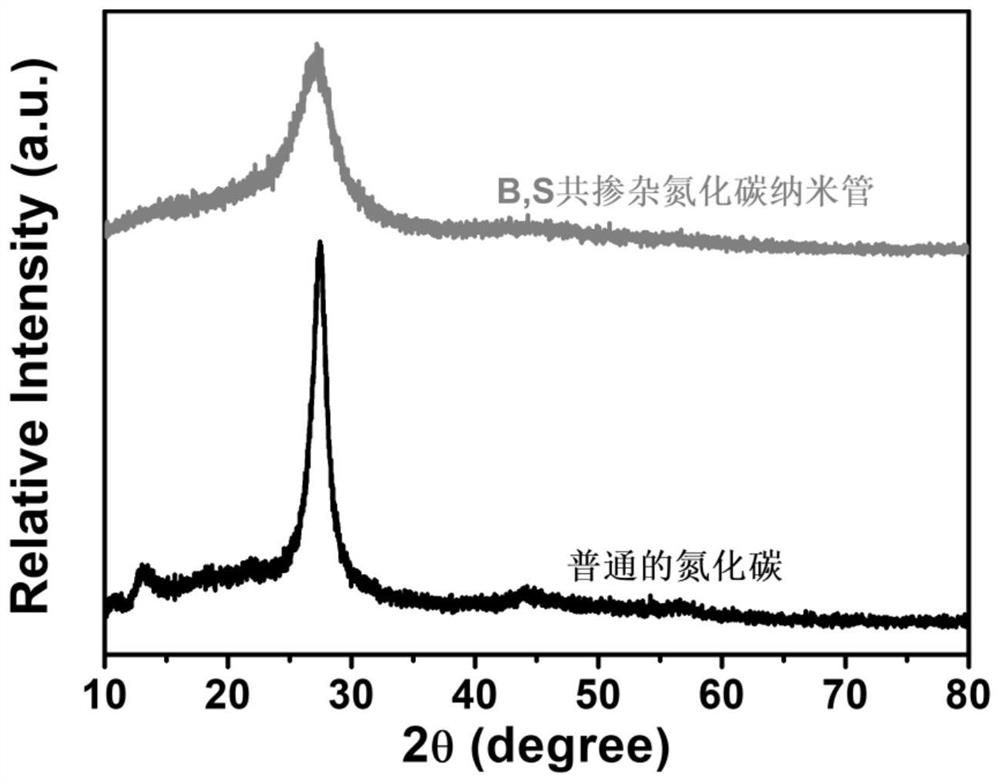

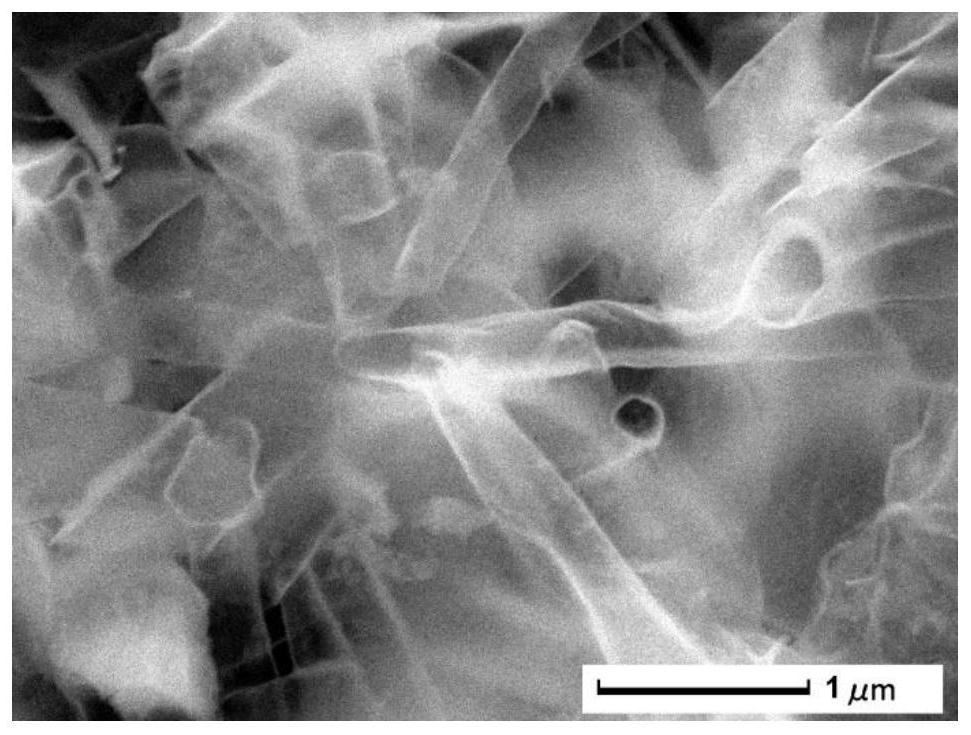

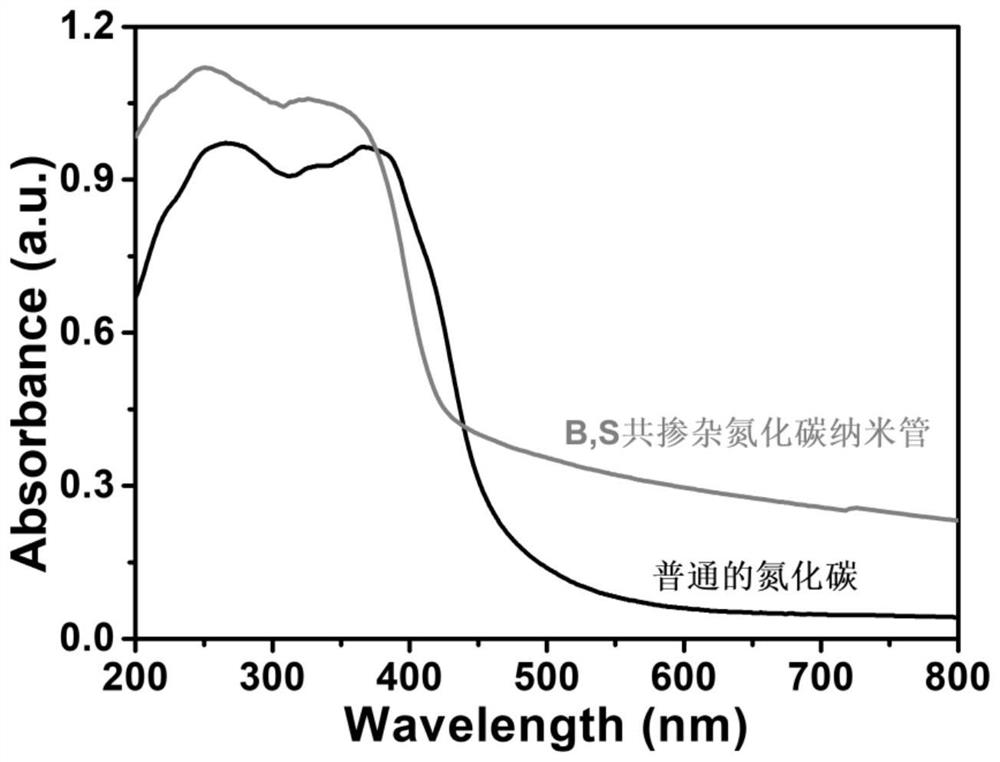

b, s co-doped carbon nitride nanotube photocatalyst and its preparation method and application

A photocatalyst and co-doping technology, which is applied in the field of photocatalysis, can solve the problems of low utilization rate of visible light, low degradation efficiency of high-concentration organic dyes, and few active sites, so as to achieve optimized energy band structure, high yield, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: B of the present invention, the preparation method of S co-doped carbon nitride nanotube photocatalyst specifically comprises the following steps:

[0023] Step 1: Put 1 g of melamine, 1 g of thiourea and 0.1 g of boric acid in a beaker filled with 40 mL of deionized water, and disperse with magnetic stirring at room temperature for 40 minutes to obtain a mixed dispersion;

[0024] Step 2: Transfer the obtained mixed dispersion to a 50mL hydrothermal reaction kettle, put it in a constant temperature oven at 180°C for 12 hours, then wait for the reaction kettle to cool down to room temperature naturally, pour the obtained mixed dispersion directly into a surface container, and put it in the freezer drying in a drier to obtain a rod-shaped intermediate;

[0025] Step 3: Weigh two parts of 1.2g intermediate respectively and place them in two crucibles. The crucibles need to be covered, and the two crucibles are placed on an ark and placed in the central tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com