Cultivation wastewater treatment process

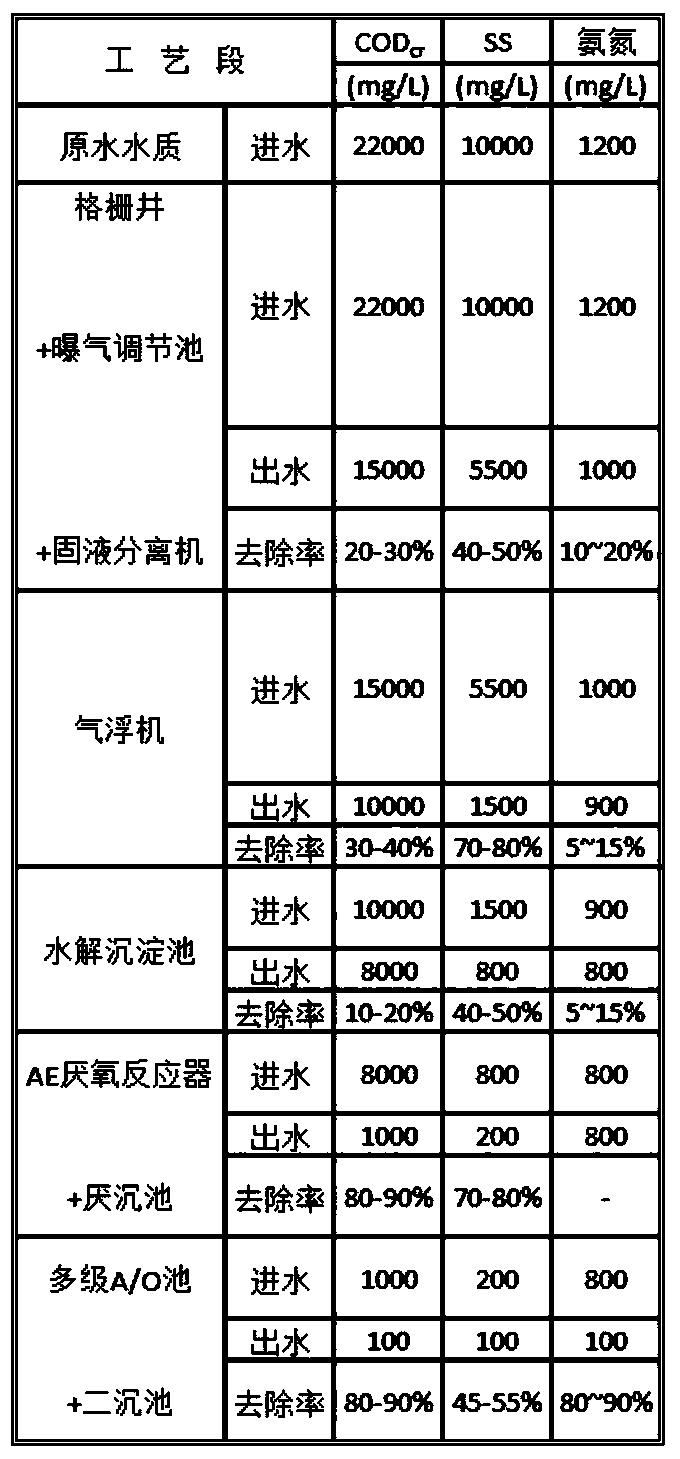

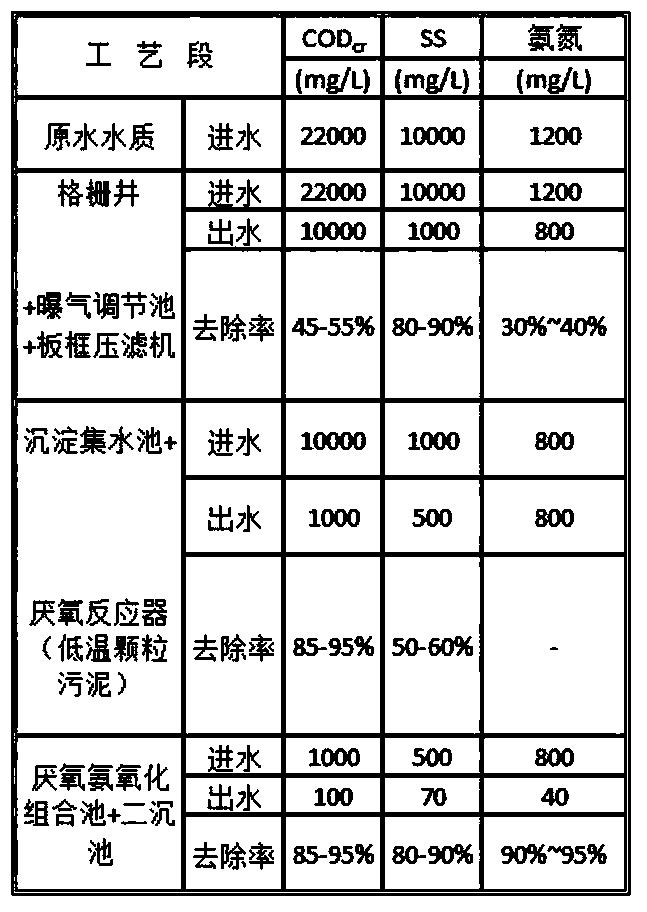

A technology for aquaculture wastewater and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of low anaerobic treatment load, high energy consumption of A/O treatment, Complicated pretreatment process and other problems, to achieve the effect of small oxygen demand, clear water quality and good water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

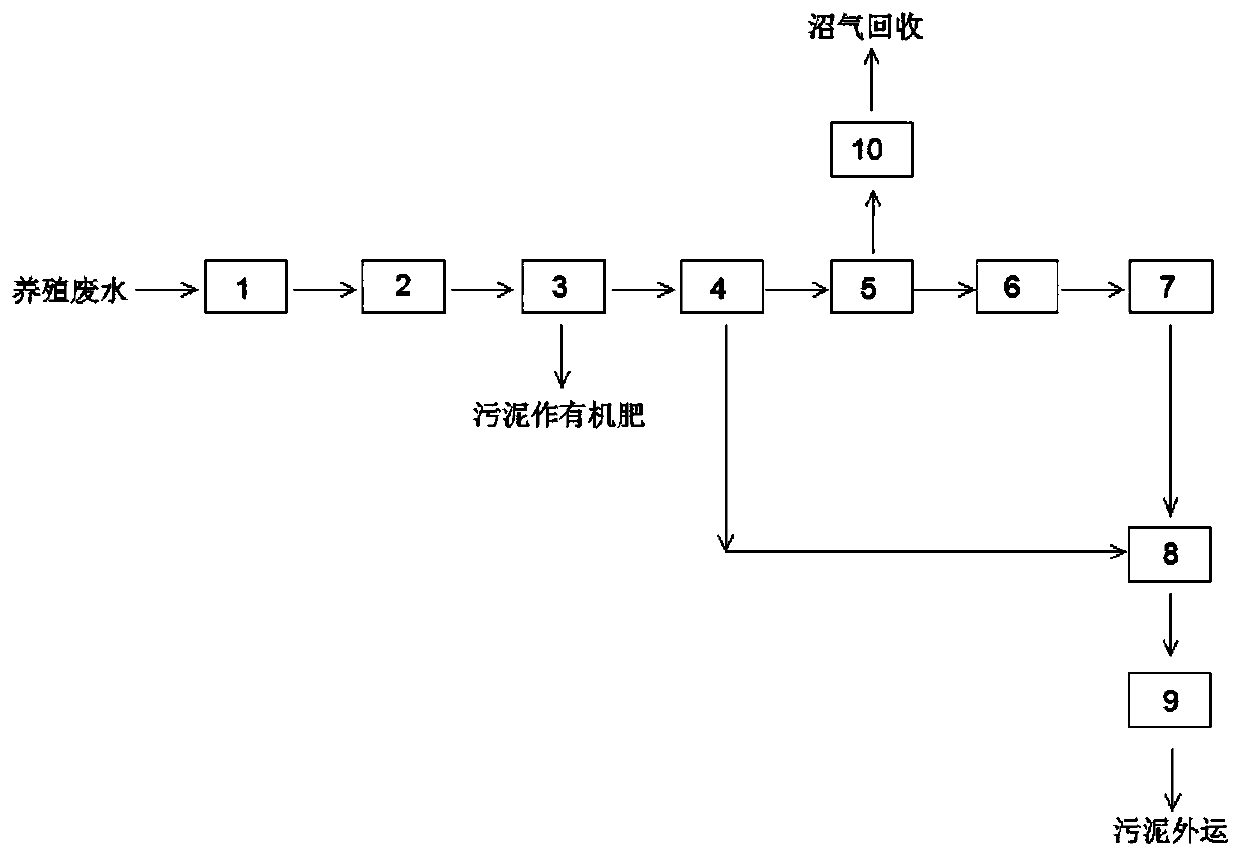

[0034] The present embodiment provides a kind of aquaculture wastewater treatment process, comprising the following steps:

[0035] a. The aquaculture wastewater flows through the mechanical grille 1 to intercept larger debris, and then flows into the aeration regulating tank 2 to adjust the water quality and quantity.

[0036] b. The effluent from the aeration regulating tank 2 is pumped to the plate and frame filter press 3 to remove suspended solids. The plate and frame filter press 3 is a diaphragm type plate and frame filter press. In this embodiment, the plate and frame filter press is used to replace the solid-liquid separator and air flotation machine. The process is simplified, the number of equipment is small, the maintenance and management are simple, the floor area is small, the treatment effect is good, and the removal rate of suspended matter can be reduced from the original 50%. Increased to 80%.

[0037] c. The plate and frame filter press 3 outlet water enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com