Method for separating m,p-cresol mixture by adopting selective oxidation catalyst

A technology of p-cresol and mixtures, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of large equipment investment constraints, cumbersome steps, and difficulty in large-scale production, and achieve low production costs and responsiveness. Ease of operation and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

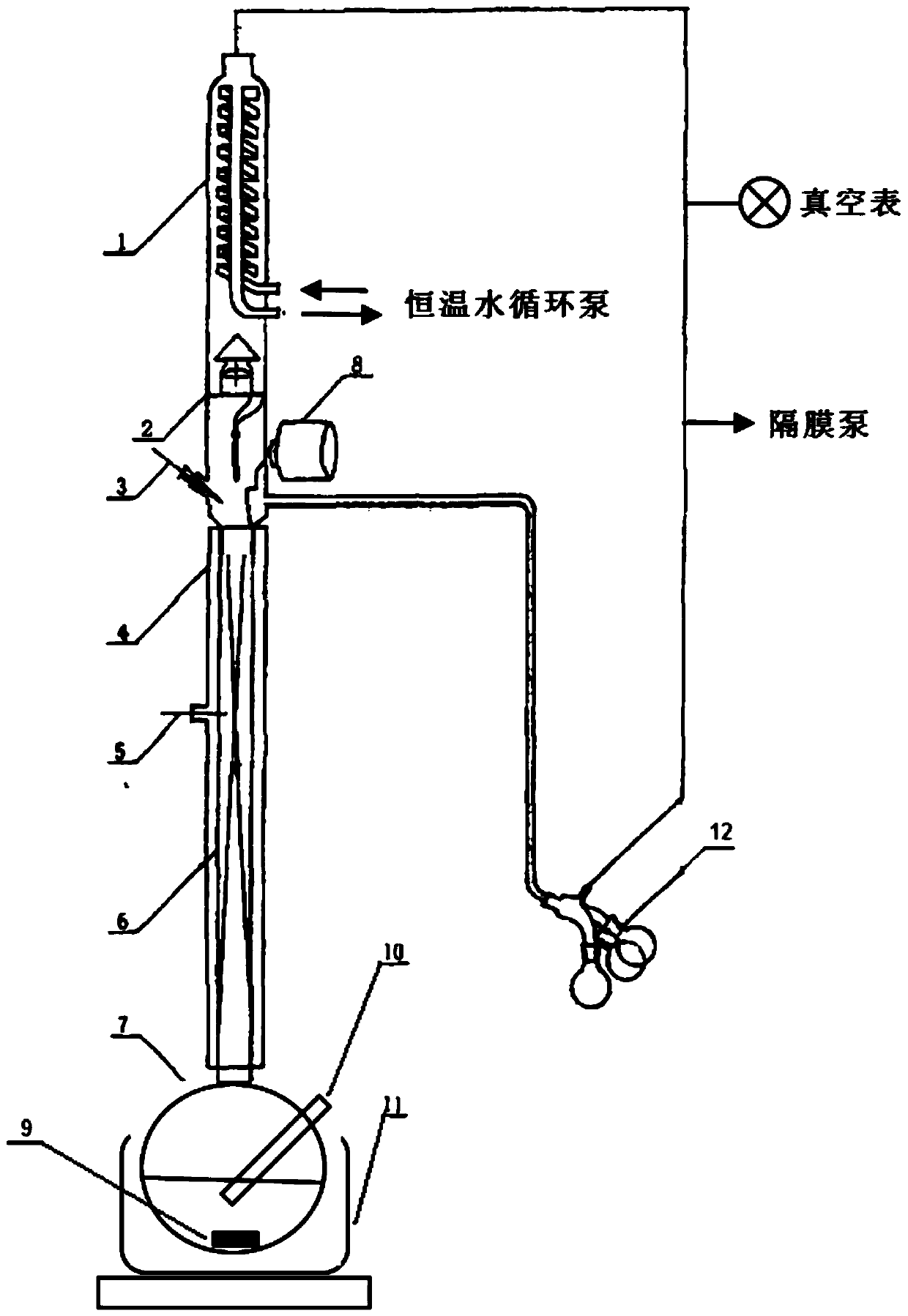

Method used

Image

Examples

Embodiment 1

[0022] 1) Oxidation of m-p-cresol mixture: with m-p-cresol mixture (1.08g, m-cresol: p-cresol=1:1, molar ratio), catalyst (4.5wt%) and solvent (acetonitrile: 80ml and water : 4ml) into the autoclave, close the autoclave and start stirring, fill with oxygen to 1.0MPa, heat up to 40°C and keep for 8 hours. Cool to room temperature after the reaction is over, vent the gas and open the reactor to collect the mother liquor after the reaction;

[0023] Determination of conversion and yield by HPLC or silica gel column chromatography: HPLC uses EclipePlus C18 column (250mm × 4.6mm, 5.0um) on Waters 1525 and 2707 autosampler with 2489UV-Vis detector High-performance liquid chromatography is performed on a certified standard sample to determine the characteristics of the product. Silica gel column Use 200-300 mesh silica gel (petroleum ether / ethyl acetate) for column chromatography analysis.

[0024] The NMR data of m-cresol oxidation products are as follows:

[0025] 1 H NMR (600M...

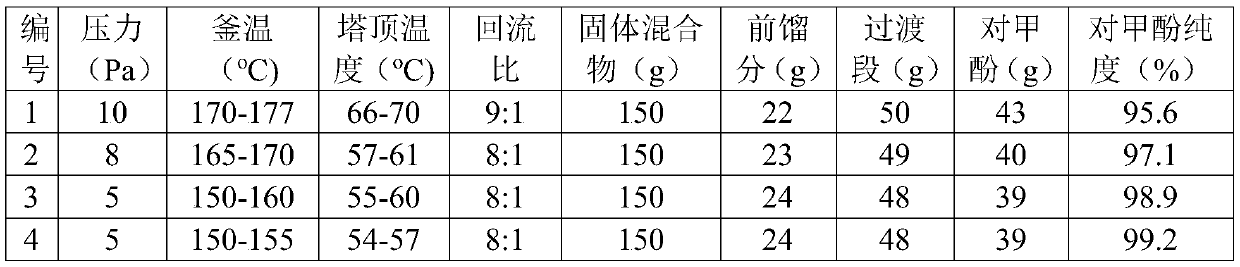

Embodiment 2 to 4

[0031] Separation of p-cresol was carried out in the same manner as in Example 1, and specific parameters were listed according to numbers 2 to 4 in Table 1 below.

[0032]

[0033] It can be seen that pure p-cresol can be obtained after rectification treatment, with a purity of more than 99%, which can meet the purity requirements of production.

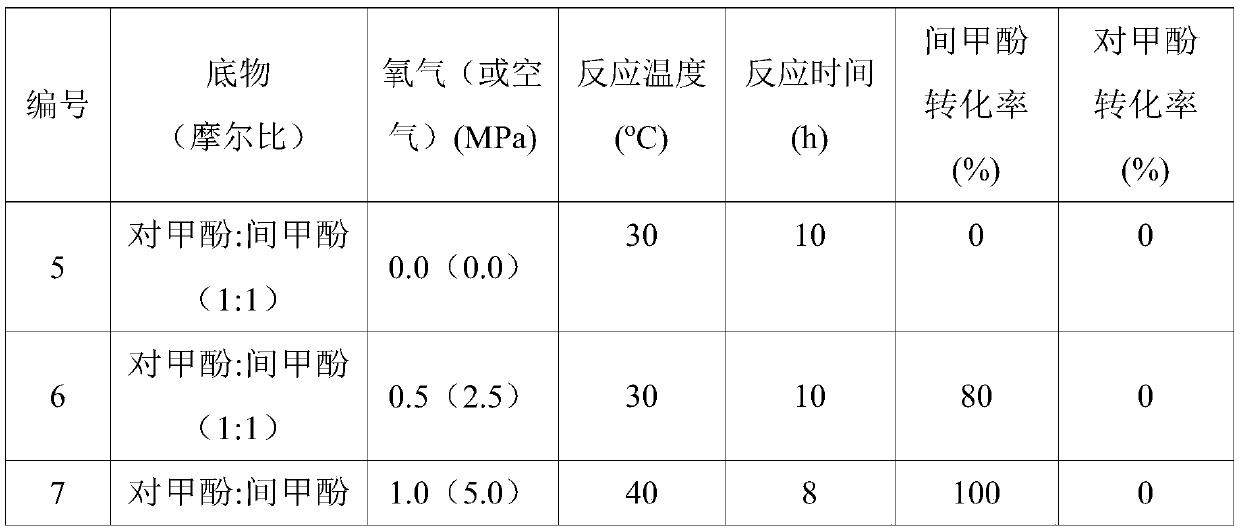

Embodiment 5 to 14

[0034] Examples 5 to 14: Comparison of catalytic oxidation results of m-p-cresol mixture by cuprous chloride catalyst.

[0035] Carry out the oxidation of m-p-cresol mixture in the same manner as step 1) in Example 1, and the reaction parameters are listed in Table 2 below.

[0036] Table 2

[0037]

[0038]

[0039] According to the data of Examples 5 to 14, it can be seen that the conversion of m-cresol can be efficiently realized by using CuCl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com