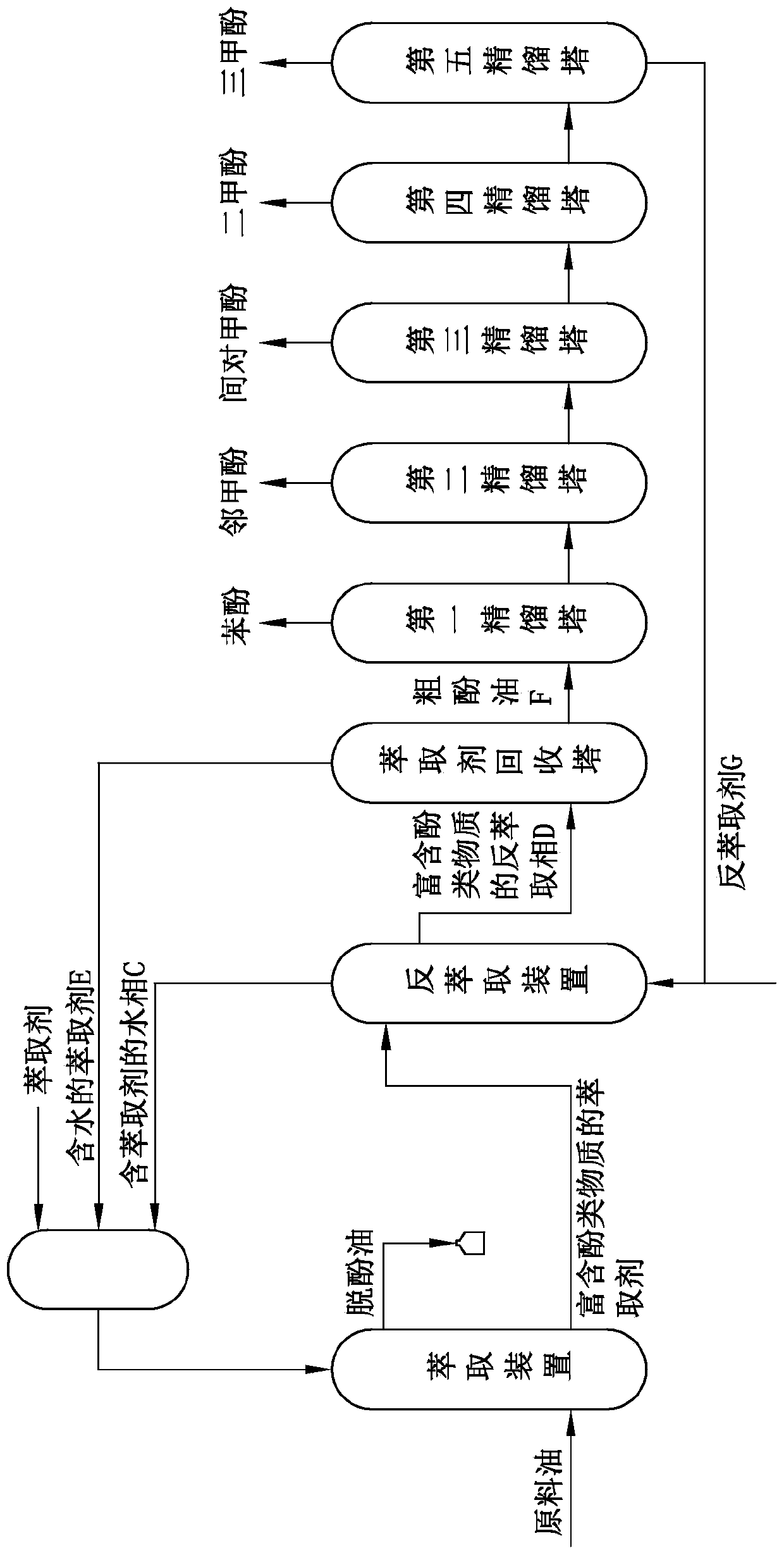

Method for extracting phenolic substances from phenol-containing raw oil

A technology of phenolic substances and raw oil, applied in the field of coal chemical industry, can solve the problem of high energy consumption of extractant recovery, achieve the effects of reduced extraction rate, high solubility, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 241.99g of ammonia solution with a concentration of 10% and 40.13g of overhead oil with a distillation range of 70-180°C and a total phenol content of 56.82% into a 500mL single-necked flask with stirring, and fully stir for 30min at normal temperature and pressure. , after liquid separation, 29.76g dephenolized oil and 251.21g phenolic-rich extract phase were obtained, and the phenolic-rich extract phase was mixed with 41.8g tower top oil to obtain 252.64g secondary phenolic-rich The extract phase of the substance and 39.43g of dephenolized oil; the phenol-containing ammonia solution is placed in a 500ml stirred flask, and 42.13g of nonylphenol is added at normal temperature and pressure for back extraction, and stirred for 20min to obtain 52.76g of The back-extraction phase rich in phenolic substances and 238.93g of ammonia-containing aqueous phase; the back-extraction phase was placed in a 150mL three-necked flask, heated to 240°C, and distilled to obtain 13.03g o...

Embodiment 2

[0047] The ammonia solution with a concentration of 10% and the overhead oil with a distillation range of 70-180°C and a total phenol content of 56.82% enter the extraction tower to separate the dephenolized oil raffinate phase and the extraction phase rich in phenolic substances. The number is 3 levels, the volume ratio of ammonia solution to tower top oil is 6:1, extraction at normal temperature and pressure, the extraction yield is 72.67%; the obtained extraction phase rich in phenolic substances is separated into the stripping tower to obtain the stripping phase And ammonia-containing aqueous solution, the number of back extraction stages is 5, the back extraction agent nonylphenol, its volume ratio to the extraction phase rich in phenolic substances is 6:1, normal temperature and pressure back extraction, the back extraction yield is 82.58% ; The back extraction phase rich in phenolic substances enters the rectification tower for separation to obtain ammonia, water, stripp...

Embodiment 3

[0049] The ammonia solution with a concentration of 10% and the overhead oil with a distillation range of 70-180°C and a total phenol content of 57.07% enter the extraction tower to separate the dephenolized oil raffinate phase and the extraction phase rich in phenolic substances. Extraction grade The number is 4 grades, the volume ratio of ammonia solution to tower top oil is 6:1, and the extraction is carried out under normal temperature and pressure, and the extraction yield is 86.86%. And ammonia-containing aqueous solution, the number of extraction stages is 7, the stripping agent nonylphenol, its volume ratio to the extraction phase rich in phenolic substances is 4:1, stripping at normal temperature and pressure, and the stripping yield is 93.84%; The back-extraction phase rich in phenolic substances enters the rectification tower to separate ammonia, water, stripping agent and crude phenol. The number of rectification stages is 10, and the vacuum is 0.07MPa. The temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com