A preparation process of thermally conductive electrical insulation foam tape for high temperature

A thermal conductivity, high temperature technology, used in adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of no flame retardant, waste of resources, no heat insulation, etc., to reduce the environment The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

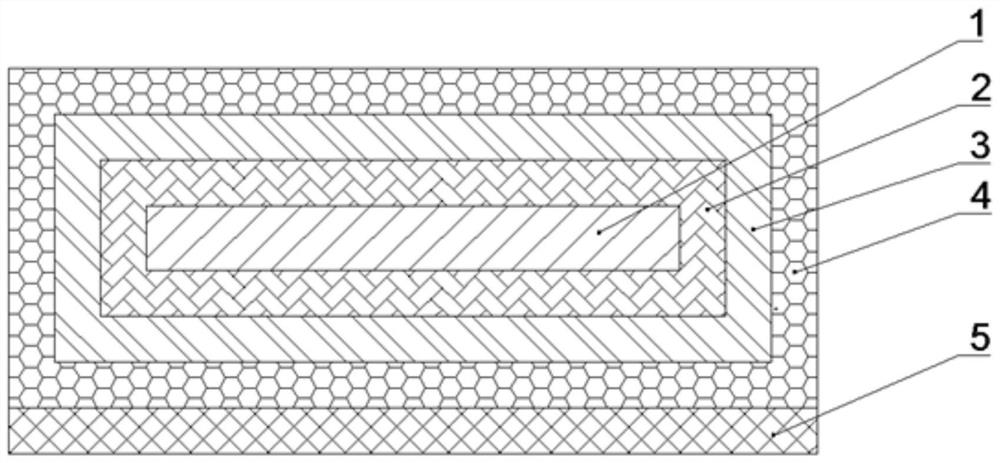

[0083] Such as figure 1 A thermally conductive electrical insulating foam tape for high temperature is shown, which is characterized in that it includes: PET ultra-thin buffer foam layer base material 1, dustproof and heat insulating layer 2, flame retardant layer 3, aluminum foil cloth 4 and embossed Release paper 5; the outer side of the PET ultra-thin buffer foam layer substrate 1 is surrounded by a dust-proof and heat-insulating layer 2; the outer side of the dust-proof and heat-insulating layer 2 is surrounded by a flame-retardant layer 3; the flame-retardant layer 3. An aluminum foil cloth 4 is arranged around the outside; one side of the aluminum foil cloth 4 away from the PET ultra-thin cushioning foam layer substrate 1 is provided with an embossed release paper 5 .

[0084] In addition, the PET ultra-thin cushioning foam layer substrate 1 is formed by the following proportions by weight:

[0085] Waste foam: 15 parts;

[0086] Polyethylene terephthalate: 8 parts;

...

Embodiment 2

[0122] Such as figure 1 A thermally conductive electrical insulating foam tape for high temperature is shown, which is characterized in that it includes: PET ultra-thin buffer foam layer base material 1, dustproof and heat insulating layer 2, flame retardant layer 3, aluminum foil cloth 4 and embossed Release paper 5; the outer side of the PET ultra-thin buffer foam layer substrate 1 is surrounded by a dust-proof and heat-insulating layer 2; the outer side of the dust-proof and heat-insulating layer 2 is surrounded by a flame-retardant layer 3; the flame-retardant layer 3. An aluminum foil cloth 4 is arranged around the outside; one side of the aluminum foil cloth 4 away from the PET ultra-thin cushioning foam layer substrate 1 is provided with an embossed release paper 5 .

[0123] In addition, the PET ultra-thin cushioning foam layer substrate 1 is formed by the following proportions by weight:

[0124] Waste foam: 30 parts;

[0125] Polyethylene terephthalate: 10 parts; ...

Embodiment 3

[0161] Such as figure 1 A thermally conductive electrical insulating foam tape for high temperature is shown, which is characterized in that it includes: PET ultra-thin buffer foam layer base material 1, dustproof and heat insulating layer 2, flame retardant layer 3, aluminum foil cloth 4 and embossed Release paper 5; the outer side of the PET ultra-thin buffer foam layer substrate 1 is surrounded by a dust-proof and heat-insulating layer 2; the outer side of the dust-proof and heat-insulating layer 2 is surrounded by a flame-retardant layer 3; the flame-retardant layer 3. An aluminum foil cloth 4 is arranged around the outside; one side of the aluminum foil cloth 4 away from the PET ultra-thin cushioning foam layer substrate 1 is provided with an embossed release paper 5 .

[0162] In addition, the PET ultra-thin cushioning foam layer substrate 1 is formed by the following proportions by weight:

[0163] Waste foam: 22.5 parts;

[0164] Polyethylene terephthalate: 9 parts; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com