Shale inhibitor for drilling fluid based on microemulsion ionic liquid and preparation method thereof

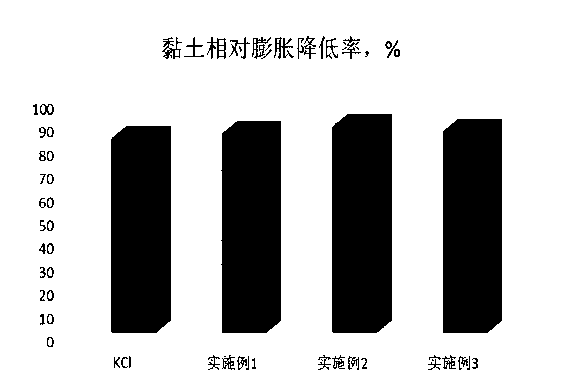

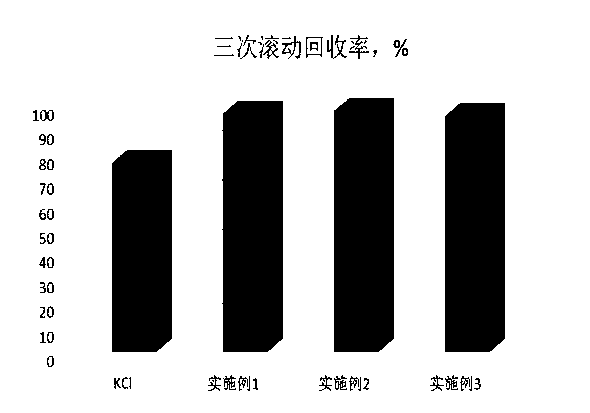

A technology of shale inhibitor and ionic liquid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor persistence of effect and large amount of shale inhibitor used, and achieve shale expansion and The dispersing inhibition effect is obvious, the shale inhibition effect is improved, and the dosage is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The specific preparation method of the present invention comprises the following steps:

[0026] (1) Add 35~45g of ionic liquid into a 200mL three-necked flat-bottomed flask, heat to 50~70°C; slowly add 10~20g of water during stirring; add 3~6g of potassium chloride, and after the dissolution is complete, add 1 ~3g sorbitan fatty acid ester, stir again evenly, add in about 30 minutes;

[0027] (2) Slowly add 10~20g of water to the above reactor, the stirring speed is 750-850 r / min, after the addition is finished, add 3~5g of polyoxyethylene sorbitan fatty acid ester, the process The medium temperature is maintained at 50~70°C, and the stirring is continued for 30 minutes;

[0028] (3) Reduce the temperature of the reactor to 30~40°C, add 26~39g of water at one time, continue to stir for 20min, then slowly add 10~15g of n-butanol dropwise, increase the stirring speed to 2000 r / min, until a transparent phase appears After cooling to room temperature, add 2~5g of nano-ca...

Embodiment 1

[0030]Add 45g of 1-butyl-3-methylimidazolium hexafluorophosphate into a 200mL three-necked flat-bottomed flask, heat to 50°C; slowly add 10g of water while stirring; add 3g of potassium chloride, and after the dissolution is complete, add 1g of sorbitan fatty acid ester S-80, stirred evenly again, and finished adding in about 30 minutes; slowly added 10g of water to the above reactor at a stirring speed of 800 r / min, and after the addition was completed, added 3g of Polyoxyethylene sorbitan fatty acid ester T-80, maintain the temperature at 50°C during the process, continue to stir for 30 minutes; lower the temperature of the reactor to 30°C, add 13g of water at one time, continue to stir for 20min, then slowly add 10g of n-butyl Alcohol, increase the stirring speed to 2000 r / min until a transparent phase appears, cool to room temperature, add 5g of 601# nano-calcium carbonate, continue stirring for 30min, and discharge to obtain shale for drilling fluid based on microemulsion ...

Embodiment 2

[0032] Add 40g of 1-butyl-3-methylimidazolium tetrafluoroborate into a 200mL three-necked flat-bottomed flask, heat to 60°C; slowly add 12g of water while stirring; add 5g of potassium chloride, and after the dissolution is complete, Add 2g of sorbitan fatty acid ester S-60, stir evenly again, and finish adding in about 30 minutes; slowly add 13g of water to the above reactor at a stirring speed of 800 r / min, after the addition is completed, add 4g The polyoxyethylene sorbitan fatty acid ester T-60, the temperature during the process was maintained at 60°C, and continued to stir for 30 minutes; the temperature of the reactor was lowered to 35°C, 8g of water was added at one time, and 12g of normal For butanol, increase the stirring speed to 2000 r / min until a transparent phase appears, cool to room temperature, add 4g of 602# nano-calcium carbonate, continue stirring for 30min, and discharge to obtain a microemulsion ionic liquid-based drilling fluid. rock inhibitors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com