Selective low-density water blocking agent and preparation and construction technology thereof

A water-blocking agent and low-density technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to increase crude oil production, difficulty in injecting chemical plugging agents, and lack of logging water-seeking data, etc. To achieve the effect of strong suspension stability, easy preparation and construction, and ensuring health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

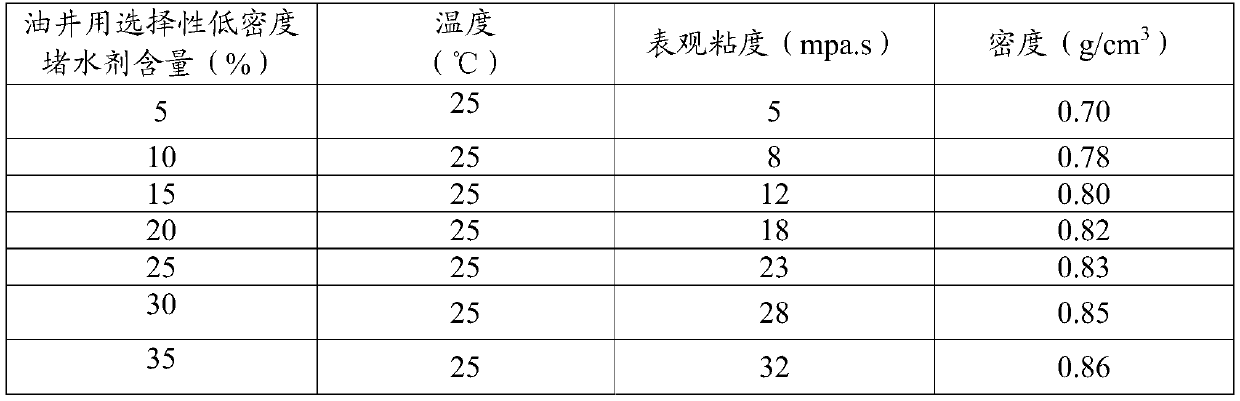

[0031] This embodiment provides a selective low-density water blocking agent, in parts by weight, the water blocking agent includes: 100 parts of superfine light calcium carbonate powder, 10 parts of silicon-based unsaturated polyester resin, polybasic fatty acid ester 3 parts, 2 parts of biopolymer, 20 parts of high temperature consolidation agent.

[0032] Wherein, the average particle diameter of the ultra-light calcium carbonate powder is not greater than 15 μm, and the calcium carbonate content in the ultra-fine light calcium carbonate powder is not less than 95 wt%. The silicon-based unsaturated polyester resin may be a high-temperature silicon-based epoxy resin, wherein the solid content is greater than 60%. The average particle size of the polybasic fatty acid ester is not greater than 15 μm, and the effective substance content thereof is not less than 80%. In this embodiment, the polybasic fatty acid is the product of the biological reaction of the oil—glycolipid BS, ...

Embodiment 2

[0043] This embodiment provides a selective low-density water blocking agent, in parts by weight, the water blocking agent includes: 100 parts of superfine light calcium carbonate powder, 5 parts of silicon-based unsaturated polyester resin, polybasic fatty acid ester 2 parts, 1 part of biopolymer, 15 parts of high temperature consolidation agent.

[0044] Wherein, the average particle diameter of the ultra-light calcium carbonate powder is not greater than 15 μm, and the calcium carbonate content in the ultra-fine light calcium carbonate powder is not less than 95 wt%. The solid content in the silicon-based unsaturated polyester resin is greater than 60%. The average particle size of the polybasic fatty acid ester is not greater than 15 μm, and the content of effective substances is not lower than 80%. The average particle size of the biopolymer is not greater than 15 μm, and the viscosity is not lower than 100 mpa.s.

[0045] This embodiment also provides a construction pr...

Embodiment 3

[0050] This embodiment provides a selective low-density water blocking agent, in parts by weight, the water blocking agent includes: 100 parts of superfine light calcium carbonate powder, 8 parts of silicon-based unsaturated polyester resin, polybasic fatty acid ester 2.5 parts, 1.5 parts of biopolymer, 18 parts of high temperature consolidation agent.

[0051] Wherein, the average particle diameter of the ultra-light calcium carbonate powder is not greater than 15 μm, and the calcium carbonate content in the ultra-fine light calcium carbonate powder is not less than 95 wt%. The solid content in the silicon-based unsaturated polyester resin is greater than 60%. The average particle size of the polybasic fatty acid ester is not greater than 15 μm, and the content of effective substances is not lower than 80%. The average particle size of the biopolymer is not greater than 15 μm, and the viscosity is not lower than 100 mpa.s.

[0052] This embodiment also provides a constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com