A biomass cogeneration operation method based on terminal electric heat pump mixed water heating

A technology of cogeneration and operation method, applied in the directions of preheating, steam generation, feed water heater, etc., can solve the problems of inapplicability and inability to control the amount of waste heat recovery, and achieve the effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] The present invention proposes a biomass cogeneration operation method based on terminal electric heat pump mixed water heating, comprising the following steps:

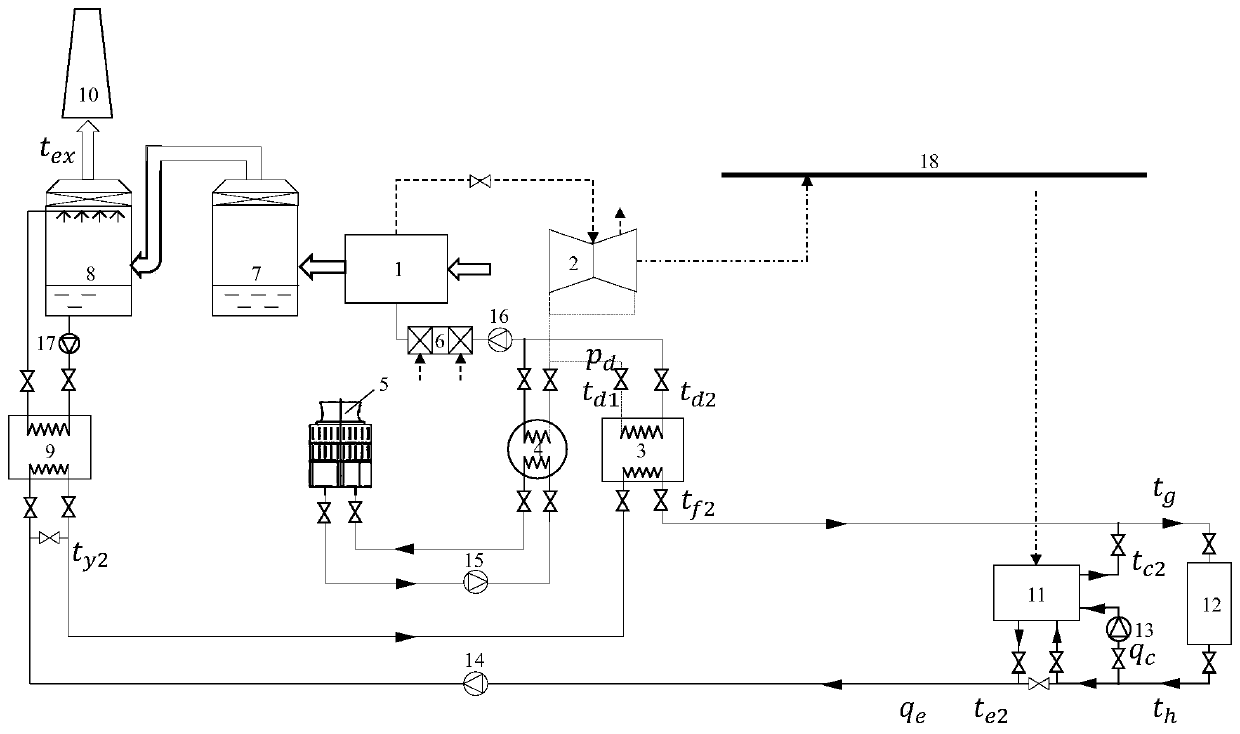

[0048] Step 1: Build a biomass cogeneration system

[0049] according to figure 1 The structure shown (the line shown by the straight line in the figure is the waterway, the line shown by the dotted line is the steam path, and the line shown by the dotted line is the circuit) to build a biomass cogeneration system, including biomass boiler 1, steam turbine 2, exhaust steam heat exchange 3, condenser 4, cooling tower 5, boiler feed water heater 6, desulfurization tower 7, waste heat recovery tower 8, flue gas spray water heat exchanger 9, chimney 10, power grid 18, terminal electric heat pump 11, user exchange Heater 12 and connecting pipeline and valve; The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com