Nitrile electrolyte for lithium metal battery and lithium metal battery using the same

A lithium metal battery and electrolyte technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of inability to use nitrile materials as main solvents and inability to form SEI films, etc., to improve long-term cycle performance, easy to operate, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

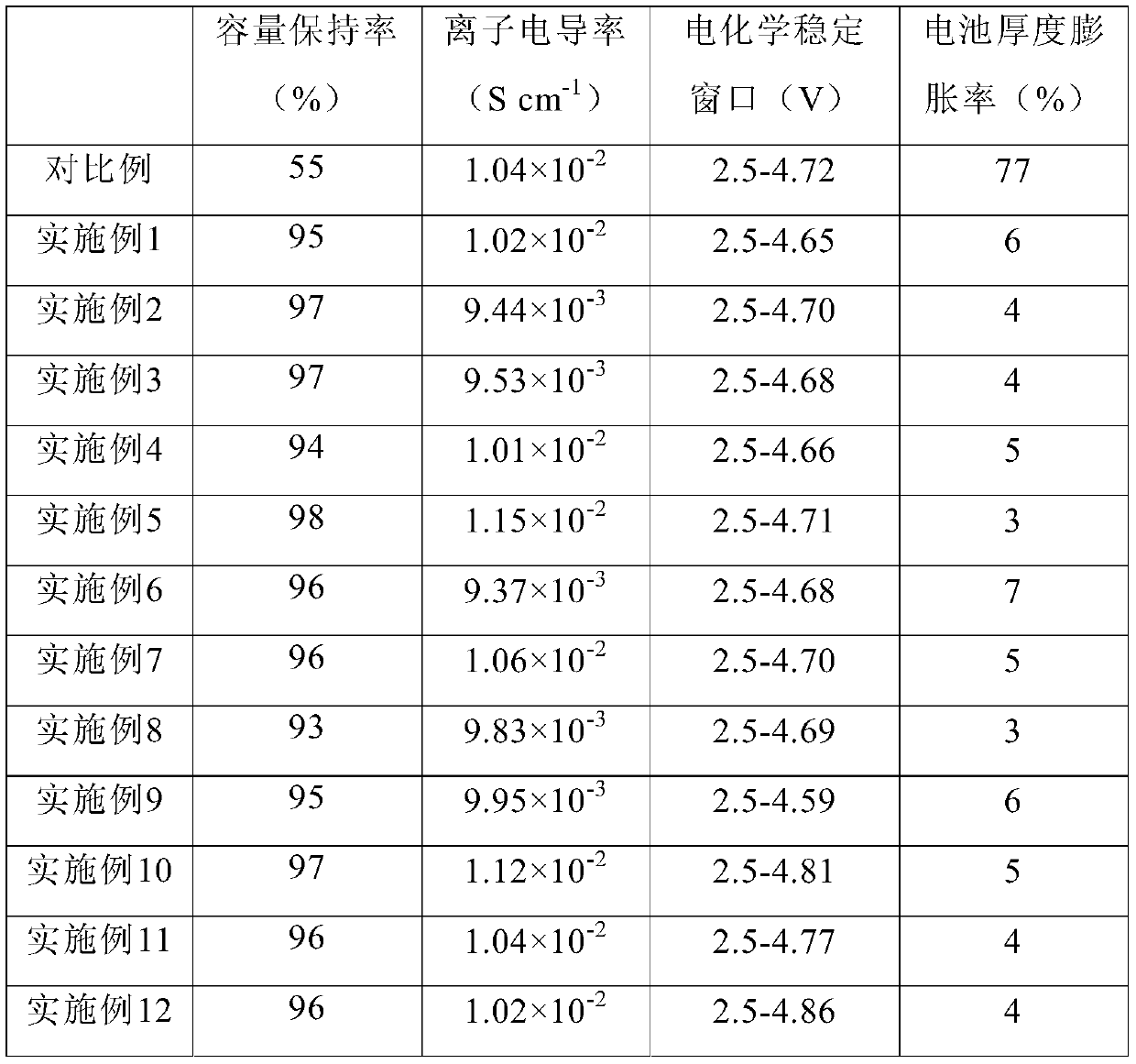

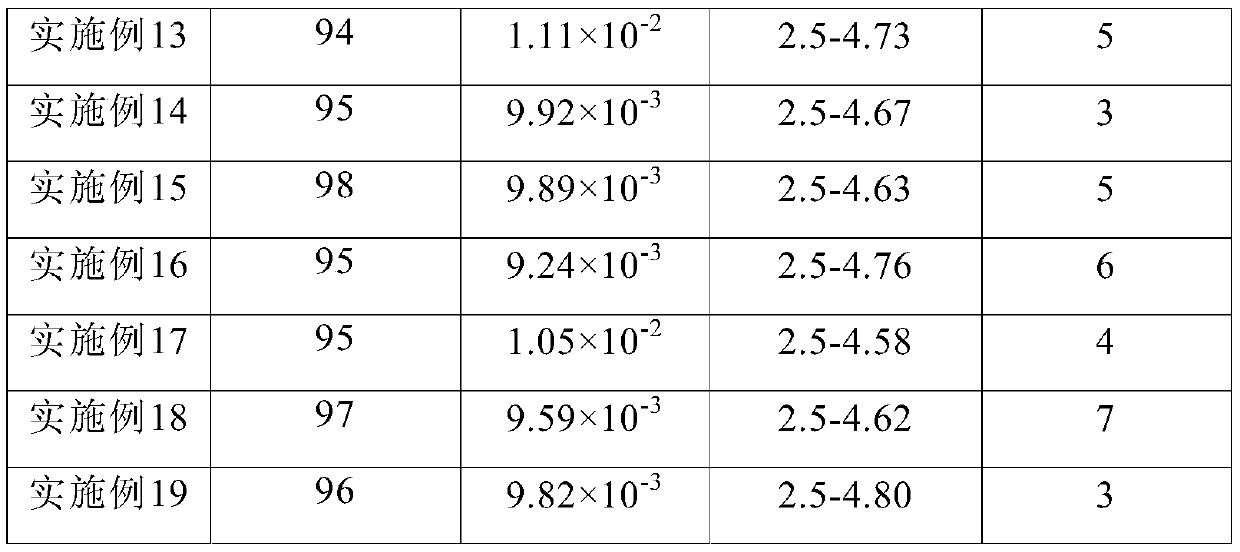

Examples

Embodiment 1

[0032] Under the protection of an inert gas atmosphere, weigh 5 g of malononitrile solid, 3 g of LiFSI powder, and 0.25 g of LiTFSI powder into a 10 mL sample bottle with an analytical balance, stir and dissolve at room temperature to obtain a transparent and uniform solution.

Embodiment 2

[0034] Under the protection of an inert gas atmosphere, use an analytical balance to weigh 5 g of malononitrile solid, 3 g of LiTFSI powder, and LiClO 4 Put 0.25g of the powder in a 10mL sample bottle, stir and dissolve at 0°C to obtain a transparent and uniform solution.

Embodiment 3

[0036] Under the protection of an inert gas atmosphere, take by weighing malononitrile solid 5g, LiFSI powder 1.5g with an analytical balance,

[0037] 1g of LiBOB powder was dissolved in a 10mL sample bottle with stirring at 60°C to obtain a transparent and uniform solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com