A kind of preparation method of water-wrapped capsule for cigarette and cigarette filter tip

A technology for water capsules and cigarettes, applied in e-liquid filter, application, tobacco and other directions, can solve the problems of high precision requirements of production instruments, rising processing and manufacturing costs, inability to preserve water for a long time, etc., so as to facilitate continuous automatic production. , low cost, small effect of individual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: capsule preparation one:

[0040] The preparation method of the present embodiment is as follows:

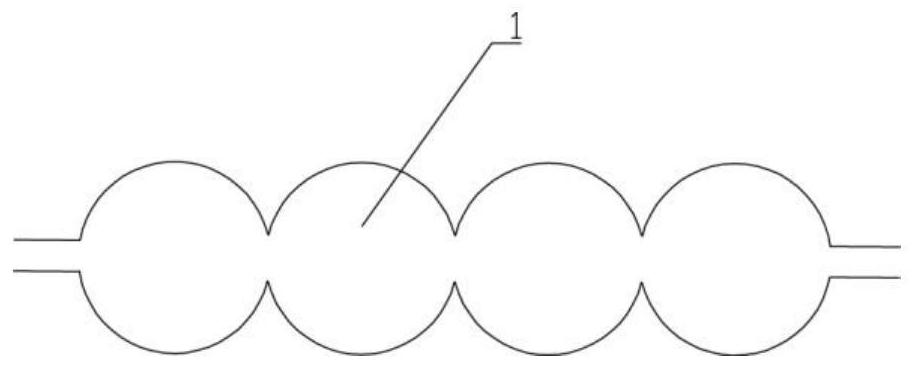

[0041] Polyethylene plastics are prepared by conventional blow molding figure 1 As shown in the pipe body, the wall thickness of the pipe body is 0.2mm, and the diameter of the ball is 4mm;

[0042] Pressurize the tube body until all the air in the tube is squeezed out, then fill in the target solution formed by mixing water, ethanol, grapefruit extract, menthol, and phenylethyl alcohol, and then pre-freeze at low temperature until the target solution is completely solidified;

[0043] After cutting the ball on the tube body with a cutter, immerse in the photocurable coating containing bisphenol A epoxy resin, or spray the photocurable coating containing bisphenol A epoxy resin evenly on the outside of the ball, Then take it out and place it in a UV curing machine, and radiate and cure it under ultraviolet light with a lamp power of 2000W and a wavelength ...

Embodiment 2

[0045] Embodiment 2: capsule preparation two:

[0046] The preparation method of the present embodiment is as follows:

[0047] Polypropylene plastic is prepared by conventional blow molding figure 1The pipe body shown in the figure has a wall thickness of 0.25mm and a ball diameter of 3.8mm;

[0048] Pressurize the tube body until all the air in the tube is squeezed out, pour into the target solution composed of water, propylene glycol, orange extract, menthol, and phenylethyl alcohol, and then cool down and freeze until the target solution is completely solidified;

[0049] After cutting the ball on the tube body with a cutter, immerse it in the mixed wax liquid composed of vegetable wax and beeswax, take it out and cool it, form a film, seal the incision, or spray vegetable wax and beeswax evenly on the outside of the ball. The wax liquid is mixed, cooled to form a film to close the incision, and the capsule is obtained after being completely solidified.

[0050] When sm...

Embodiment 3

[0051] Embodiment 3: capsule preparation three:

[0052] The preparation method of the present embodiment is as follows:

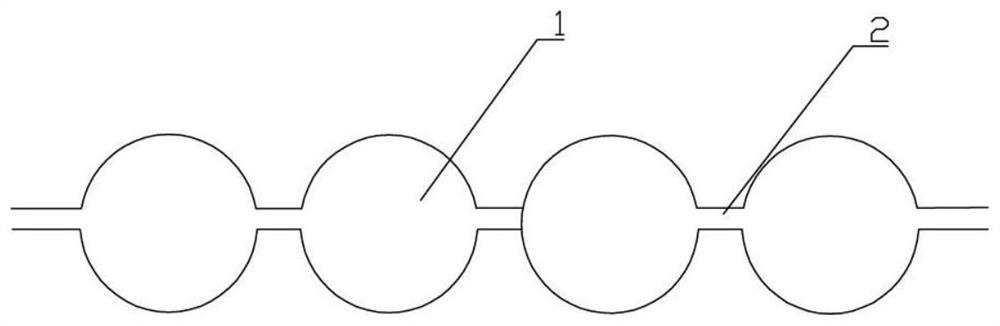

[0053] Polyethylene resin is prepared by conventional blow molding method figure 2 As shown in the tube body, the wall thickness of the tube body is 0.2mm, the diameter of the ball is 4mm, and the diameter of the thin tube is 0.1mm;

[0054] Extract the air in the tube, pour into the target solution composed of water, glycerin, rose extract, lemon extract, eugenol, and maltol;

[0055] Extrude and cut the ball with a high-temperature cutter at 50-100°C, preferably at 85°C, seal the cut with polyethylene resin under the action of high temperature, and obtain capsules after cooling.

[0056] Put the capsule in a hot air rotary oven with a temperature of 40-90°C and a wind speed of 1-5m / s, preferably a hot air rotary oven with a wind speed of 70°C and a wind speed of 4m / s, and take it out after rotating for about 10 minutes to obtain a more regular shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com