Brick fragments with water treatment plant sludge as raw material and preparing method and application thereof

A technology for sludge and bricks in a water supply plant, applied in the field of materials, can solve problems such as huge costs, restrictions, negative environmental impact, etc., and achieve the effects of increasing the utilization ratio, good durability, and improving drainage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the remaining sludge from the water supply plant is used as the raw material for making bricks.

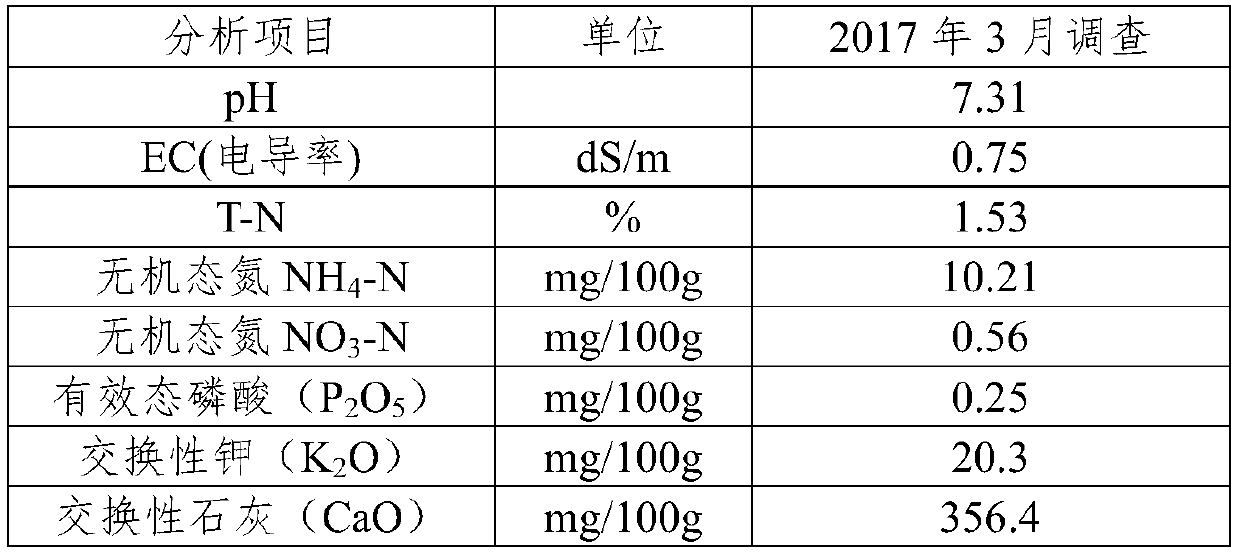

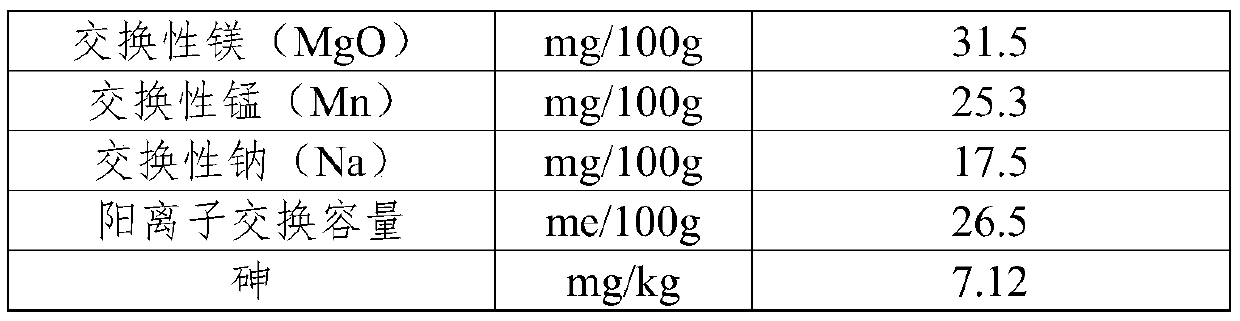

[0050] The composition of the excess sludge is shown in Table 1.

[0051] Table 1

[0052]

[0053]

[0054] 1. Treat the remaining sludge to obtain sludge powder:

[0055]Use a dehydrator to reduce the water content of the excess sludge to 50wt%, then use a dry crusher to reduce the water content to 48wt%, and crush the particle size to 10-30mm. Put the sludge particles into the kiln for forced drying, and the moisture content is reduced to 14wt%. Still further, the sludge particles are crushed into granules (with a particle diameter of 10-19 mm) by using a pulverizer, so that the water content is reduced to 7 wt%.

[0056] Forcibly drying the sludge in the kiln to reduce the moisture content to below 15wt% can improve the pulverization efficiency. That is to say, if the moisture content of the sludge is higher than 20%, and the pulverizer is ...

Embodiment 2

[0077] The difference between this embodiment and embodiment 1 is: the amount of raw materials is different.

[0078] The raw materials used in this embodiment are shown in Table 4.

[0079] Table 4

[0080] The sludge powder prepared in step 1

25kg

Mountain sand (true sand)

75kg

6kg

Nonionic Surfactant (Emulsifier TX-10)

8kg

[0081] Using the same test method and test conditions as in Example 1, the bricks prepared in this example were tested for performance, and the results are shown in Table 5.

[0082] table 5

[0083]

Embodiment 3

[0085] The difference between this embodiment and embodiment 1 is: the amount of raw materials is different.

[0086] The raw materials used in this embodiment are shown in Table 6.

[0087] Table 6

[0088] The sludge powder prepared in step 1

75kg

Mountain sand (true sand)

25kg

6kg

Nonionic Surfactant (Emulsifier NP-10)

8kg

[0089] Using the same test method and test conditions as in Example 1, the performance test of the brick prepared in this example is carried out, and the results are shown in Table 7.

[0090] Table 7

[0091]

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com