Organosilicon three-proofing adhesive and preparation method and application thereof

A technology of three-proof glue and silicone, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor tear resistance, complicated production process, high production cost, etc., and achieve fast curing speed , the preparation method is simple, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

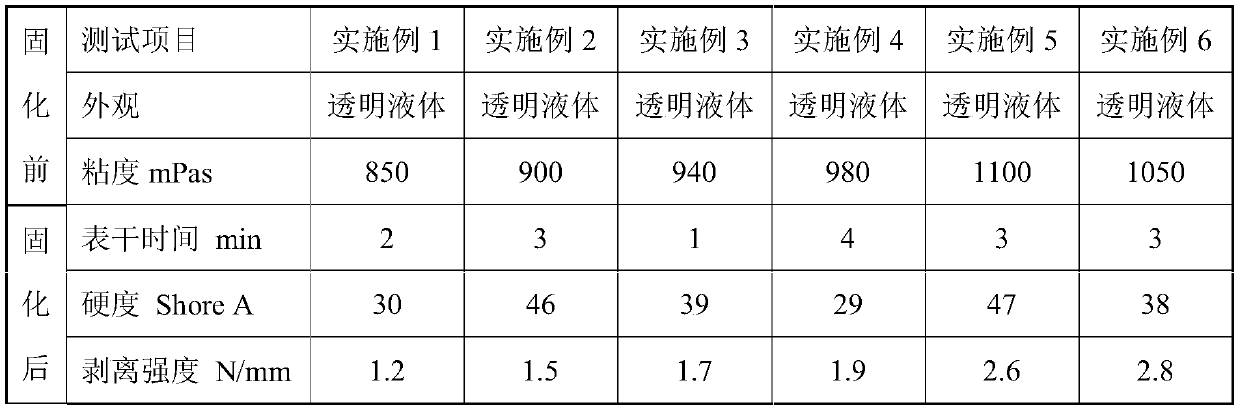

Embodiment 1

[0035] This embodiment provides a silicone conformal adhesive and a preparation method thereof.

[0036] A silicone conformal adhesive, which consists of the following raw materials in terms of mass percentage: terminal group hydrogen-containing silicone oil crosslinking agent 14%, vinyl MQ resin 70%, tackifier 5%, inhibitor 3% and terminal vinyl group 8% silicone oil, the total mass of the above-mentioned raw materials is 100%; in addition, a platinum catalyst (Castel catalyst) with a mass of 5 ppm is added.

[0037] The preparation method is as follows:

[0038] (1) Preparation of the vinyl component: Mix 8g of terminal vinyl silicone oil and 70g of liquid vinyl MQ resin with a vinyl content of 2.4%, stir evenly, react at 110°C and cool to room temperature, then add 5g of Adhesive vinylmethyldimethoxysilane, to obtain a clear and transparent vinyl component;

[0039] (2) Preparation of three anti-adhesive glue: the vinyl component obtained in step (1), 3g inhibitor 1-ethyn...

Embodiment 2

[0041] For the preparation of one-component, fast-curing, solvent-free silicone conformal adhesive:

[0042] A silicone conformal adhesive, which is composed of the following raw materials in terms of mass percentage: 9% of terminal group hydrogen-containing silicone oil crosslinking agent, 2% of fumed silica, 68% of vinyl MQ resin, 5% of tackifier, inhibitor 0.006% of platinum catalyst (Castel catalyst) and 13% of vinyl-terminated silicone oil with a mass concentration of 5-50ppm, the mass concentration of the above-mentioned raw materials is 100%; in addition, a platinum catalyst (Castel catalyst) of 50ppm in mass concentration is added. ).

[0043] The preparation method is as follows:

[0044] (1) Preparation of the vinyl component: Mix 13g of terminal vinyl silicone oil and 68g of liquid vinyl MQ resin with a vinyl content of 2.0%, add 2g of fumed silica in batches, stir evenly, and heat at 110°C Cool to room temperature after the reaction, then add 5g tackifier vinyltr...

Embodiment 3

[0047] For the preparation of one-component, fast-curing, solvent-free silicone conformal adhesive:

[0048] A silicone conformal adhesive, which is composed of the following raw materials in terms of mass percentage: 12% of terminal group hydrogen-containing silicone oil crosslinking agent, 2% of fumed silica, 73% of vinyl MQ resin, 1% of tackifier, inhibitor Agent 1% and vinyl-terminated silicone oil 11%, the total quality of the above-mentioned raw materials is 100%; in addition, a platinum catalyst (Caster catalyst) with a material quality of 25ppm is added.

[0049] The preparation method is as follows:

[0050] (1) Preparation of the vinyl component: Mix 11g of terminal vinyl silicone oil with 73g of liquid vinyl MQ resin with a vinyl content of 1.8%, add 2g of fumed silica in batches, stir evenly, and heat at 110°C Cool to room temperature after the reaction, and then add 1g of tackifier vinyltriethoxysilane to obtain a clear and transparent vinyl component;

[0051] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com