Solid peony seed oil and processing method thereof

A processing method and technology of peony seed oil, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of harming human health, reducing the nutritional value of peony seed oil and digestibility, etc. The effect of oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

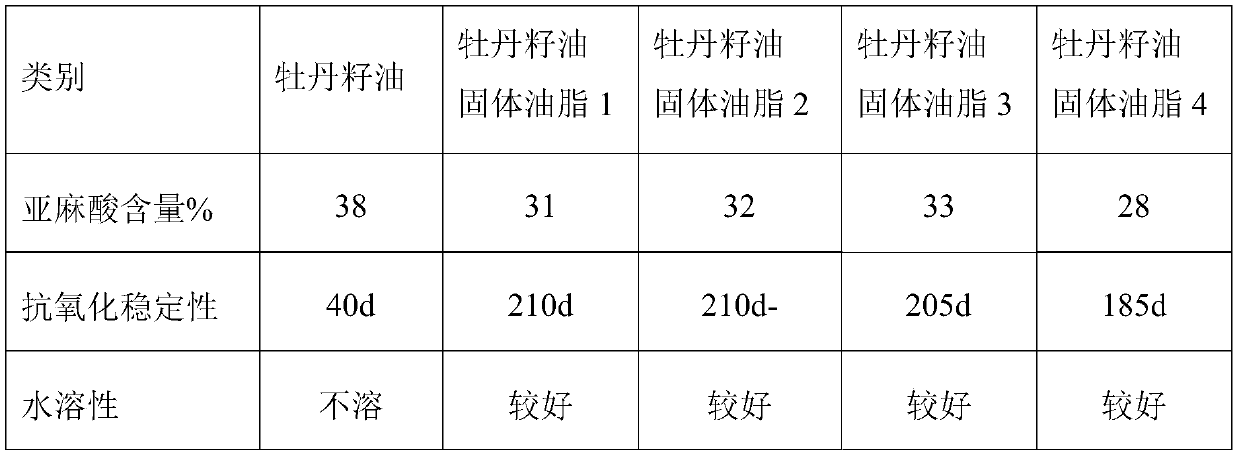

Examples

Embodiment 1

[0019] (1) Mix soy protein isolate, β-cyclodextrin, water, peony seed oil, and emulsifier uniformly at a temperature of 60°C to obtain a first mixture;

[0020] Among them, the mass ratio of soy protein isolate and β-cyclodextrin is 1.5:1, the total amount of soy protein isolate and β-cyclodextrin accounts for 32.5wt% of the first mixture; the amount of peony seed oil accounts for the first mixture 25wt%; the emulsifier uses sodium caseinate and sodium glycerol monostearate with a mass ratio of 1:1, the amount of emulsifier accounts for 1.5wt% of the first mixture; the balance is water;

[0021] (2) The first mixture obtained in step (1) is homogenized 3 times under 40MPa conditions with an ATS high-pressure homogenizer for 3 minutes each time to obtain an emulsion-like mixture without the presence of particulate solids, at a feed temperature of 50 ℃, the inlet air temperature is 180°C, and the outlet air temperature is 90°C, spray drying is performed, and then cooled to room tempe...

Embodiment 2

[0023] (1) Mix soy protein isolate, β-cyclodextrin, water, peony seed oil, and emulsifier uniformly at a temperature of 55°C to obtain a first mixture;

[0024] Among them, the mass ratio of soy protein isolate and β-cyclodextrin is 1:1.5, the total amount of soy protein isolate and β-cyclodextrin accounts for 30wt% of the first mixture; the amount of peony seed oil accounts for 20wt% of the first mixture %; The emulsifier uses sodium caseinate and sodium glycerol monostearate with a mass ratio of 1:1, and the amount of emulsifier accounts for 2wt% of the first mixture; the balance is water;

[0025] (2) The first mixture obtained in step (1) was homogenized 3 times under 35MPa conditions with an ATS high-pressure homogenizer for 3 minutes each time to obtain an emulsion-like mixture without the presence of particulate solids. At a feeding temperature of 40 ℃, the air inlet temperature is 170°C, and the air outlet temperature is 80°C, spray drying is performed, and then cooled to r...

Embodiment 3

[0027] (1) Mix soy protein isolate, β-cyclodextrin, water, peony seed oil, and emulsifier uniformly at a temperature of 70°C to obtain a first mixture;

[0028] Among them, the mass ratio of soy protein isolate and β-cyclodextrin is 1.5:2, the total amount of soy protein isolate and β-cyclodextrin accounts for 35wt% of the first mixture; the amount of peony seed oil accounts for 25wt% of the first mixture %; The emulsifier uses sodium caseinate and sodium glycerol monostearate with a mass ratio of 1:1, and the amount of emulsifier accounts for 2.5wt% of the first mixture; the balance is water;

[0029] (2) The first mixture obtained in step (1) is homogenized 3 times under the condition of 45MPa with an ATS high-pressure homogenizer for 3 minutes each time to obtain a mixture without particulate solids and an emulsion, at a feed temperature of 60 ℃, the inlet air temperature is 190°C, and the outlet air temperature is 100°C, spray drying is performed, and then cooled to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com