Bullet train chassis oxidization film automatic grinding system

An oxide film and chassis technology, applied in the direction of grinding automatic control device, grinding machine, grinding frame, etc., can solve the problem of not providing automatic grinding equipment, etc., and achieve a small footprint, uniform processing quality, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

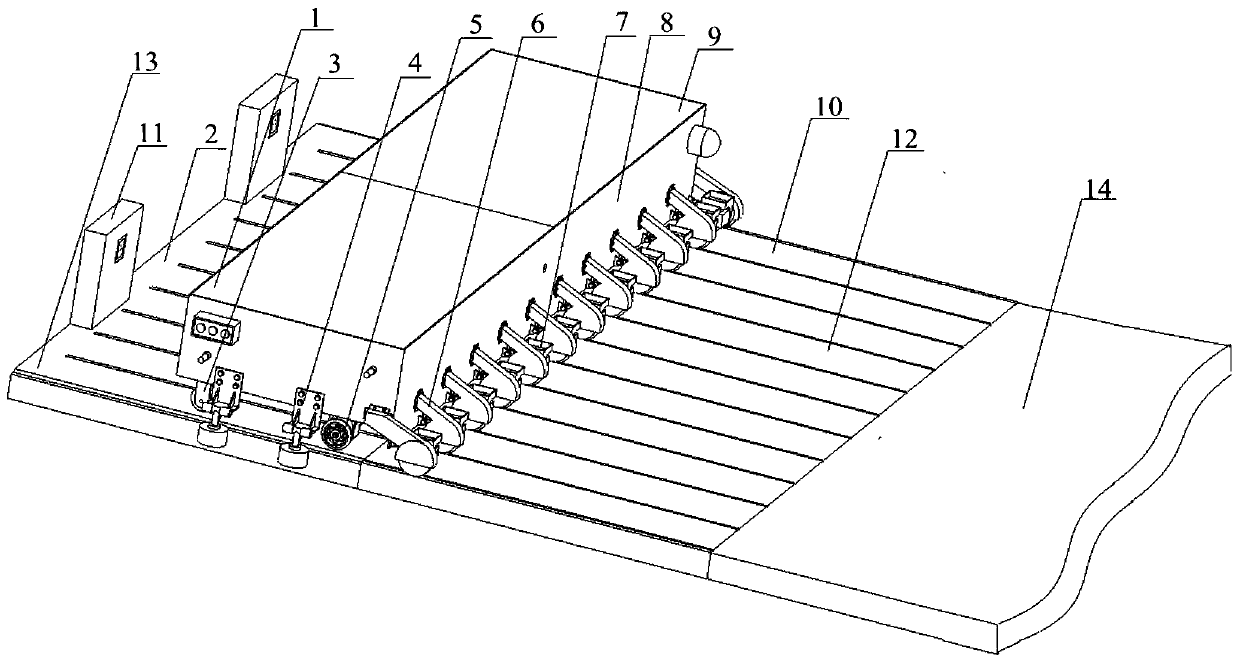

[0038] In order to achieve the above object, the automatic polishing system for the oxide film of the chassis of the motor vehicle proposed by the present invention includes three parts: the mobile device 1 , the polishing device 7 and the workbench 12 .

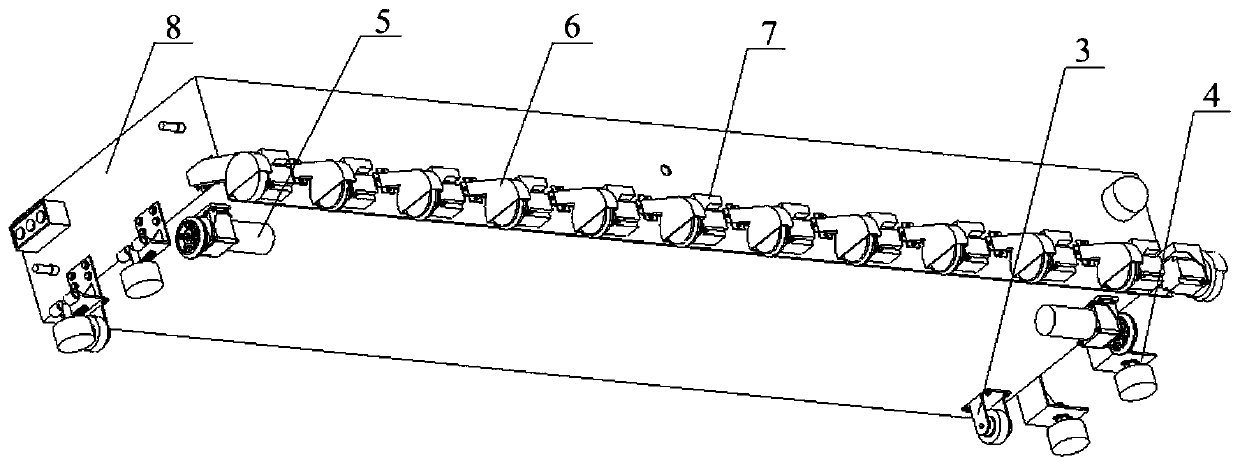

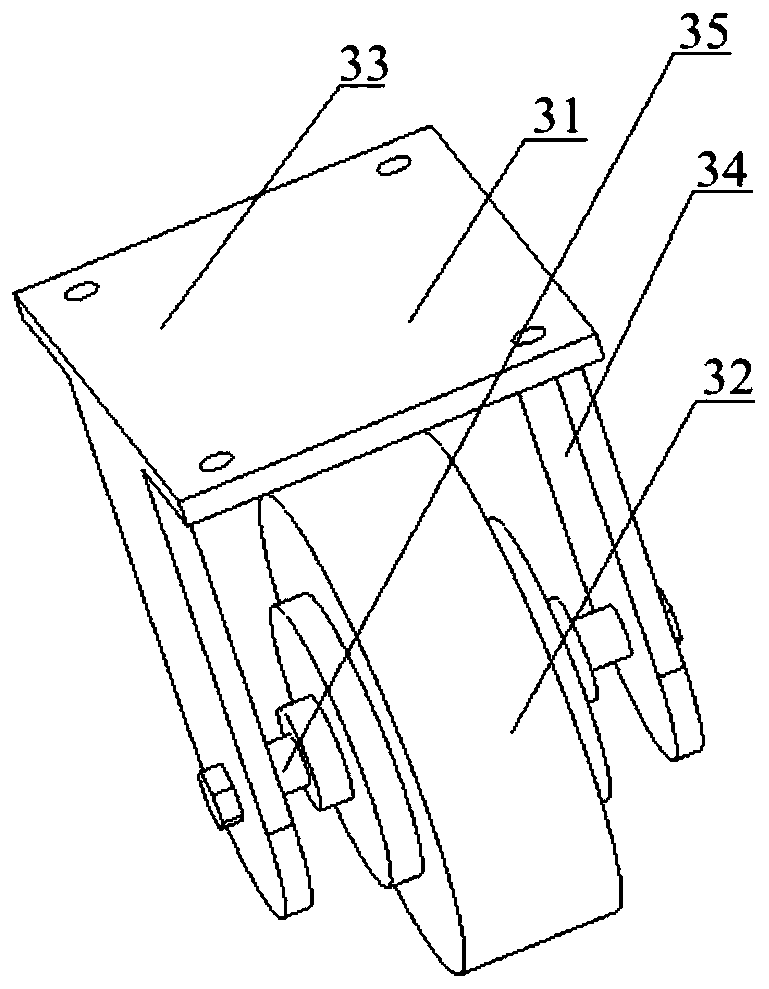

[0039] The overall layout of the automatic grinding system is as follows: figure 1 and figure 2As shown, on the workbench 12 or on the workpiece 14 extending from the workbench 12, the mobile device 1 and the vehicle body 8 supported by it are provided. In a preferred embodiment, the workbench 12 is fixed and has the same width as the chassis of the motor car. The chassis of the motor car is slightly higher than the workbench. The chassis of the motor car is spliced by twelve aluminum profiles. Both are the same size. The mobile device 1 includes a driving wheel assembly 5 , a driven wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com