Air-permeable and seepage-proof carpet and production technology thereof

A technology of breathable anti-seepage blanket and production process, which is applied in marine engineering, layered products, water conservancy projects, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

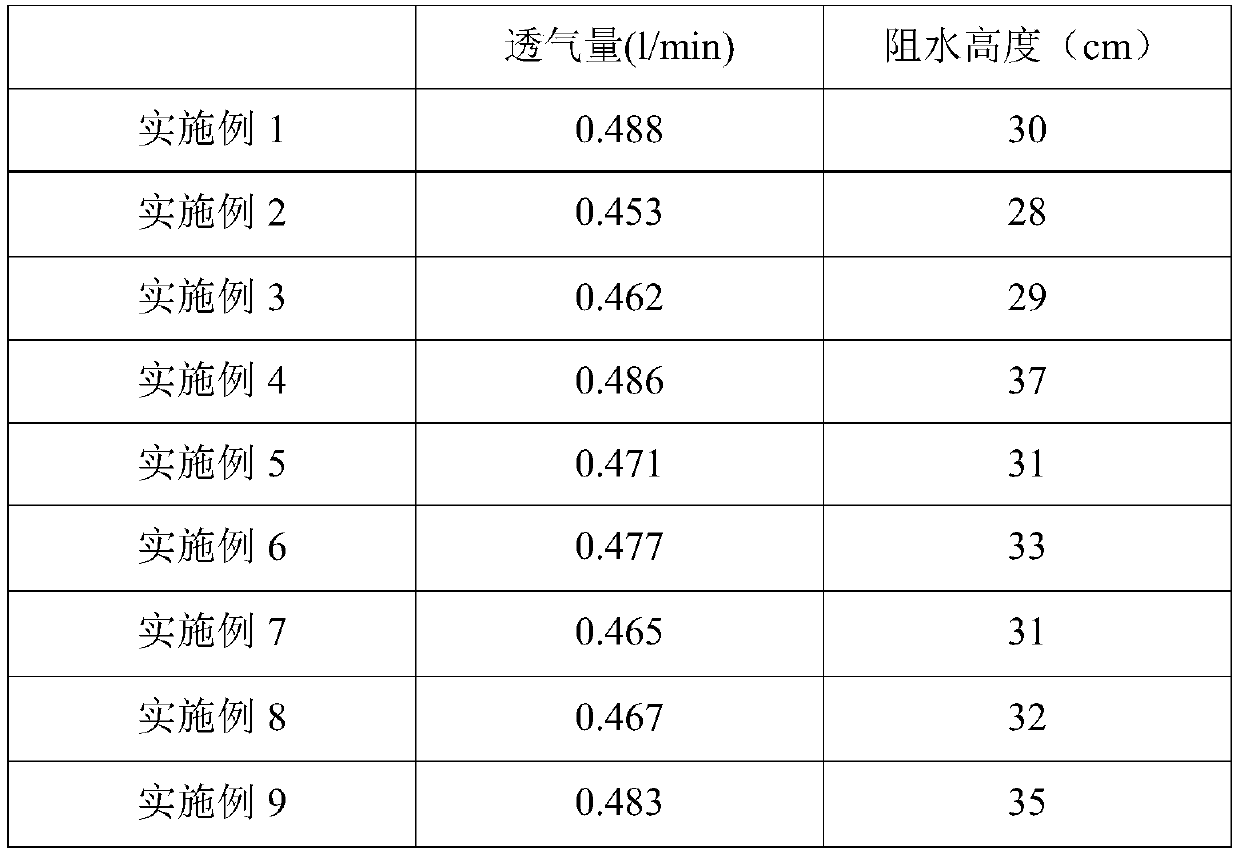

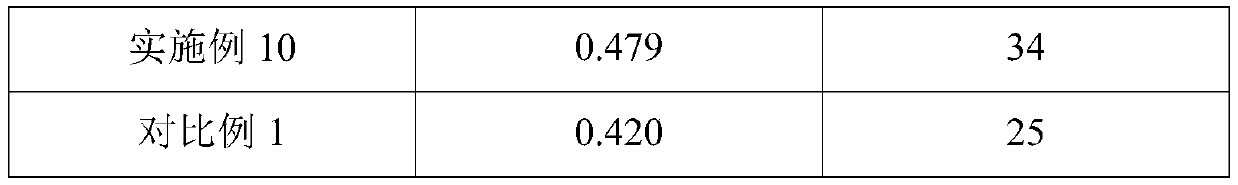

Examples

Embodiment 1

[0064] This embodiment provides a breathable and anti-seepage blanket, the breathable and anti-seepage blanket comprises an upper air-permeable layer, a lower air-permeable layer and an air-permeable and anti-seepage sand layer clamped between them, the upper air-permeable layer is an upper air-permeable fiber Cloth, the lower air-permeable layer is a lower air-permeable fiber cloth, and the air-permeable anti-seepage sand layer includes 70g of sand, 20g of hydrophobic organic materials, and 0.1g of expansive particles; the expansive particles are bentonite particles with a particle diameter of 5mm ; The hydrophobic organic material is a linear aliphatic epoxy resin with a particle size of 0.045mm; the particle size of the sand is 5mm.

[0065] The production process of the above-mentioned air-permeable anti-seepage blanket comprises the following steps:

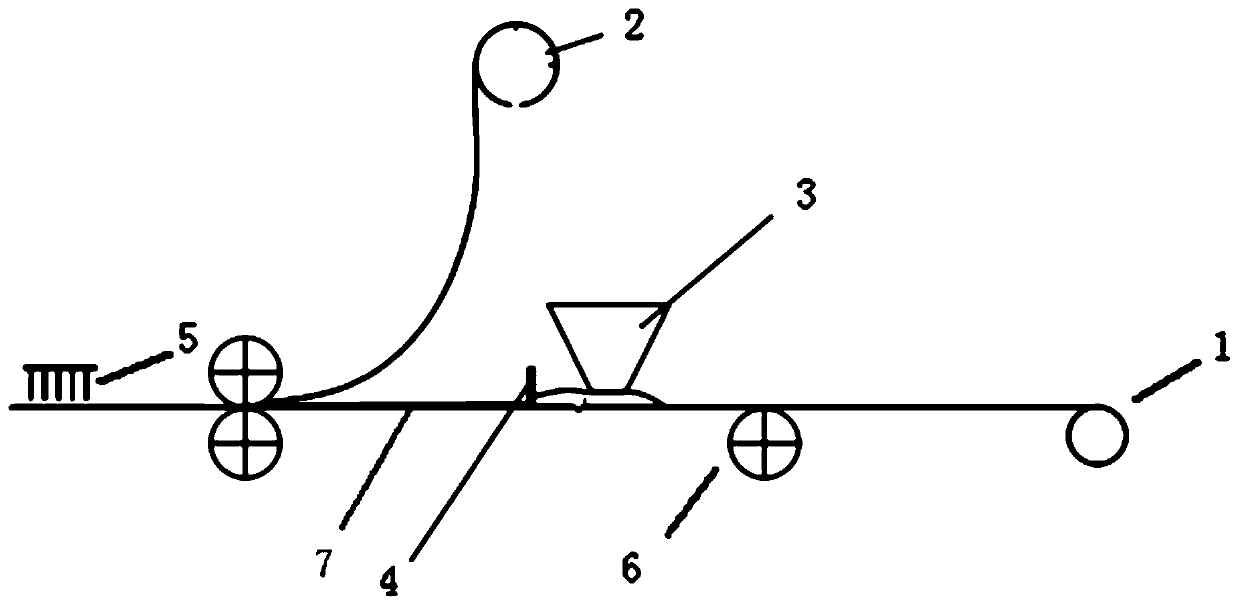

[0066] 1) Coating acrylic resin on the rotating roller 6, the lower air-permeable fiber cloth 1 is laid on the rotating ro...

Embodiment 2

[0071] This embodiment provides a breathable and anti-seepage blanket, the breathable and anti-seepage blanket comprises an upper air-permeable layer, a lower air-permeable layer and an air-permeable and anti-seepage sand layer clamped between them, the upper air-permeable layer is an upper air-permeable fiber Cloth, the lower air-permeable layer is a lower woven cloth, and the air-permeable anti-seepage sand layer includes 99g of sand, 0.01g of hydrophobic organic material, and 50g of expandable particles; the expandable particles are clay particles with a particle diameter of 0.001mm ; The hydrophobic organic material is an alicyclic epoxy resin with a particle size of 1mm; the particle size of the sand is 0.045mm.

[0072] The production process of the above-mentioned air-permeable anti-seepage blanket comprises the following steps:

[0073] 1) Coating water-based epoxy resin on the rotating roller 6, laying the lower layer of woven cloth on the rotating roller 6, and trans...

Embodiment 3

[0078] This embodiment provides a breathable and anti-seepage blanket, the breathable and anti-seepage blanket comprises an upper air-permeable layer, a lower air-permeable layer and an air-permeable and anti-seepage sand layer clamped between them, the upper air-permeable layer is an upper air-permeable fiber Cloth, the lower air-permeable layer is a lower air-permeable fiber cloth, and the air-permeable anti-seepage sand layer includes 80g of sand, 10g of hydrophobic organic materials, and 10g of expansive particles; the expansive particles are clay particles with a particle diameter of 0.075mm ; The hydrophobic organic material is glycidyl ether epoxy resin with a particle size of 0.1 mm; the particle size of the sand is 0.1 mm.

[0079] The production process of the above-mentioned air-permeable anti-seepage blanket comprises the following steps:

[0080] 1) Coating water-based epoxy resin on the rotating roller 6, laying the lower air-permeable fiber cloth 1 on the rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com