Method for purifying attapulgite

A technology of attapulgite and attapulgite, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem that ultrasonic devices cannot be widely used in large-scale production, purified attapulgite cannot be effectively utilized, and the specific surface area has not been improved. problems, to achieve the effect of abundant reserves, low cost and optimized process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Primary purification of attapulgite:

[0028] The attapulgite clay raw ore is ball milled and vibrating screened to obtain a powder with a particle size of about 5um. Weigh 10g of the original soil powder for later use. Weigh 0.3g of sodium hexametaphosphate and add it to 1L solution to prepare a mass fraction of 3 % dispersant solution, and then pour it into the colloid mill and mix it evenly with the original soil powder, so that the attapulgite original soil is fully dispersed in the dispersant solution. The mixed solution was centrifuged and washed once for one hour and taken out for later use.

[0029] B. Secondary purification of attapulgite:

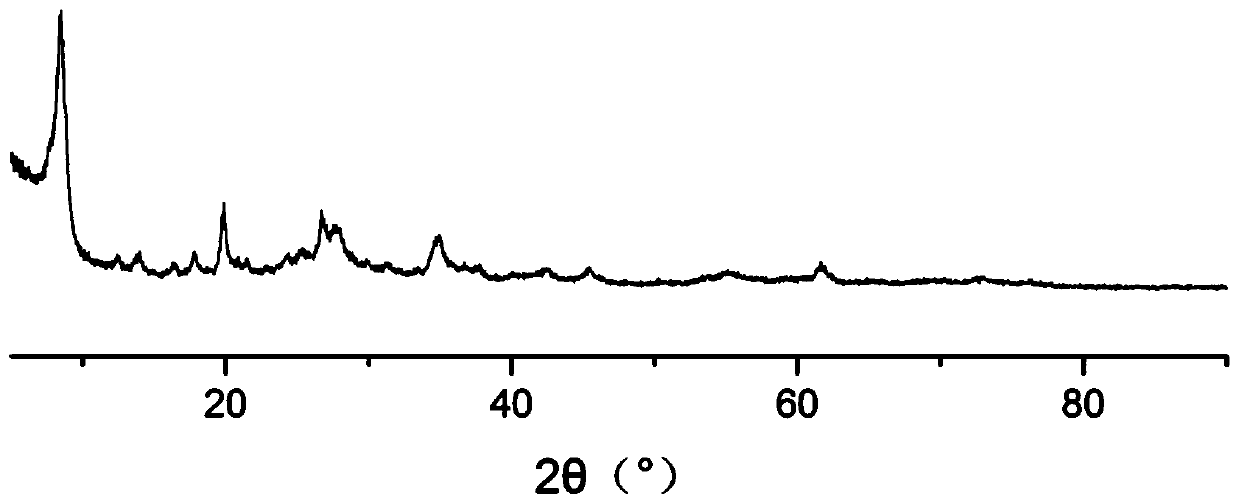

[0030] The attapulgite treated with the dispersant in step A is added to 200ml of 1mol / L hydrochloric acid solution, after fully mixing in the colloid mill for 1 hour, then the acidified attapulgite is centrifuged and added to 200ml of 1mol / L ammonia solution, Stir in a magnetic stirrer for 30 minutes and then centrifu...

Embodiment 2

[0035] Weigh 0.8g of sodium pyrophosphate and add it to 1L solution to prepare a dispersant solution with a mass fraction of 8%, then pour it into a colloid mill and mix it evenly with the original soil powder to fully disperse the attapulgite original soil in the dispersant solution.

[0036] Others are the same as embodiment 1.

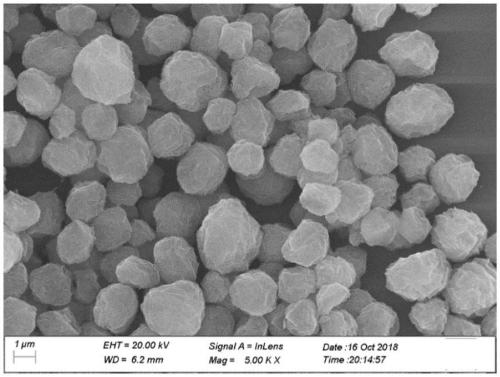

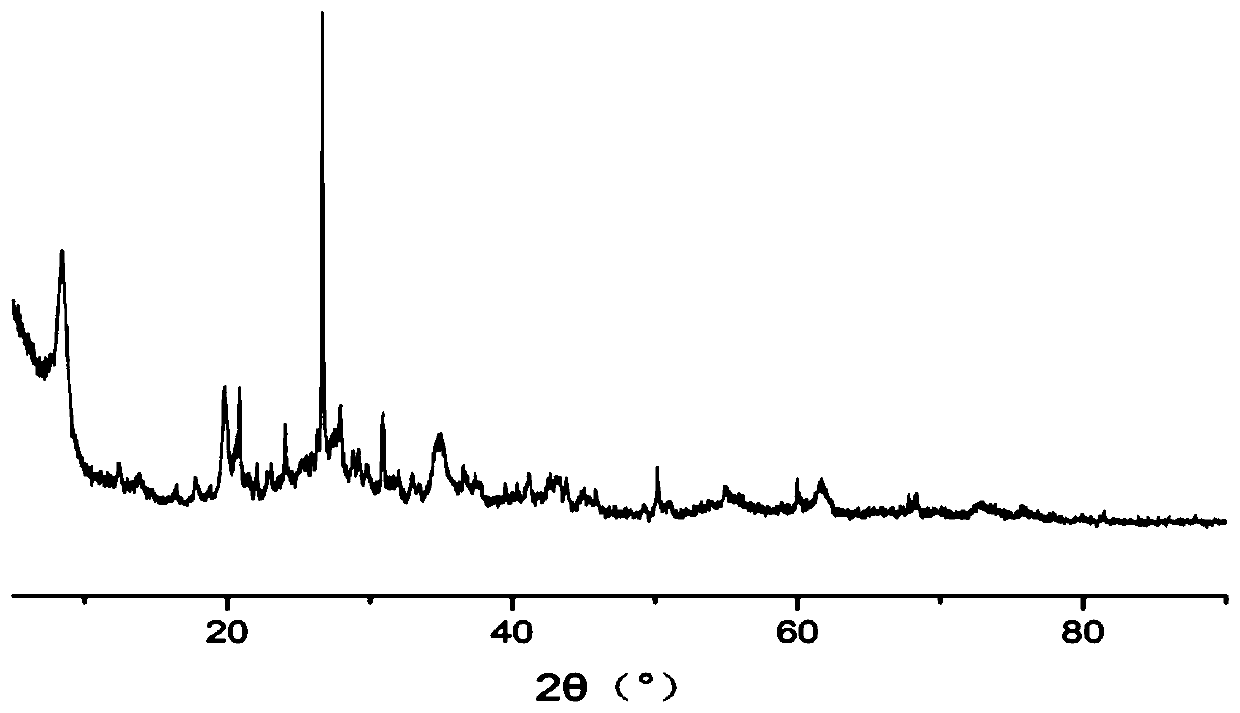

[0037] Specific data: SEM photo see Figure 5 , X-ray diffraction pattern see Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com