Corrosion inhibitor for steam flooding oil field produced water and preparation method thereof

A corrosion inhibitor and steam flooding technology, which is used in mining wastewater treatment, chemical instruments and methods, descaling and water softening, etc. It can save raw materials, meet the requirements of green and environmental protection, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

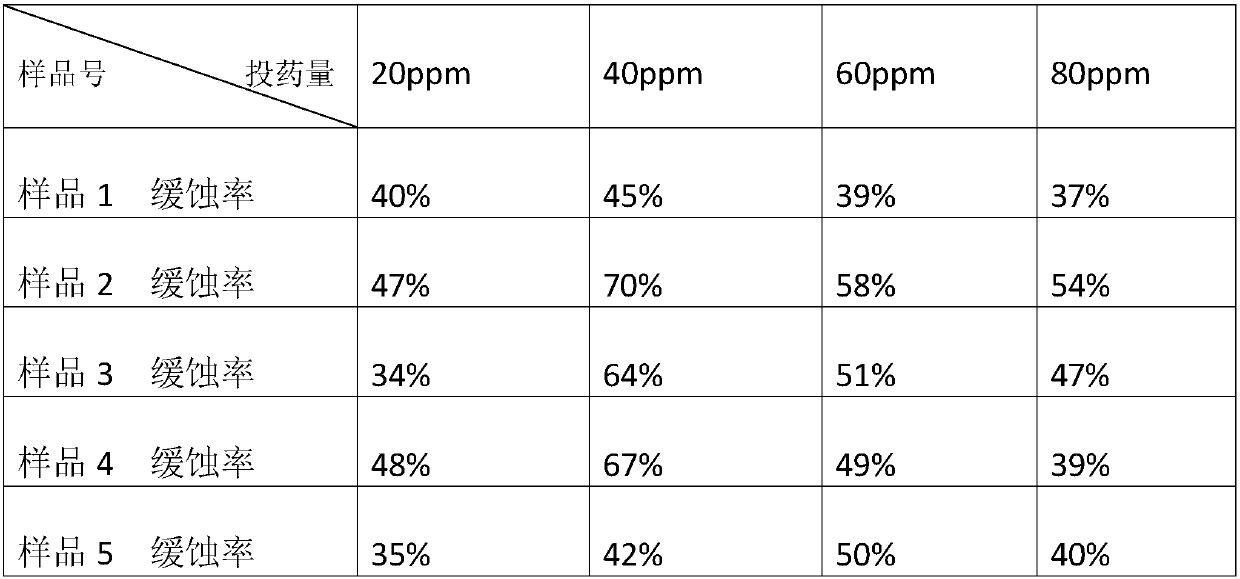

Examples

Embodiment 1

[0034]The preparation method of corrosion inhibitor sample 1:

[0035] 1) Add oleic acid and diethylenetriamine with a molar ratio of 1:1 into a sealed stainless steel reaction kettle, add a carrier agent (xylene solution with a mass fraction of 20%), react at 80°C for 20h, and then undergo amidation dehydration reaction, and then raise the temperature to 200°C for 10 hours through cyclodehydration reaction, and the reaction is completed when the system does not produce water;

[0036] 2) Add 0.5 ml of quaternizing agent (benzyl chloride) dropwise into the reaction system, react at a temperature of 60° C., and react for 8 hours to obtain the corrosion inhibitor for steam flooding oilfield produced water of the present invention—sample 1.

Embodiment 2

[0038] The preparation method of corrosion inhibitor sample 2:

[0039] 1) Add oleic acid and diethylenetriamine with a molar ratio of 1:1.2 into a sealed stainless steel reaction kettle, add a carrier agent (xylene solution with a mass fraction of 20%), react at 170°C for 4 hours, and then undergo amidation dehydration reaction, and then raise the temperature to 210°C for 4 hours through cyclodehydration reaction, and the reaction is completed when the system does not produce water;

[0040] 2) Add 1.3ml of quaternizing agent (benzyl chloride) dropwise into the reaction system, react at a temperature of 90° C., and react for 4 hours to obtain the corrosion inhibitor for steam flooding oilfield produced water of the present invention—sample 2.

Embodiment 3

[0042] The preparation method of corrosion inhibitor sample 3:

[0043] 1) Add oleic acid and diethylenetriamine with a molar ratio of 2:3 into a sealed polytetrafluoroethylene reactor, add a carrier agent (petroleum ether solution with a mass fraction of 20%), react at 50°C for 10h, and then Amidation dehydration reaction, and then raise the temperature to 240°C for 3 hours through cyclodehydration reaction, and the reaction is completed when the system does not produce water;

[0044] 2) Add 2.3ml of quaternizing agent (dimethyl sulfate) dropwise into the reaction system, react at a temperature of 60° C., and react for 8 hours to obtain the corrosion inhibitor-sample 3 for steam flooding oilfield produced water according to the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com