High-strength polyolefin composite material and its preparation method

A composite material and polyolefin technology, applied in the field of high-strength polyolefin composite materials and its preparation, can solve problems that have not been solved well, and achieve the effect of high structure retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, polypropylene (PP) weighed 48.85g, C60 weighed 0.75g, cerium trifluoromethanesulfonate (CAS No. 76089-77-5, cerium trifluoromethanesulfonate, Ce(OTf) 3 ) weighed 0.4g, put them into a blast drying oven and dried at 90°C for 24 hours; then put the dried raw materials into a torque rheometer for melt blending, and recorded the torque data. The blending temperature was 180 ℃, rotating speed 60r / min, blending time 8min, prepared PP / C60 / Ce(OTf) 3 composite material. Its reaction mechanism is as follows:

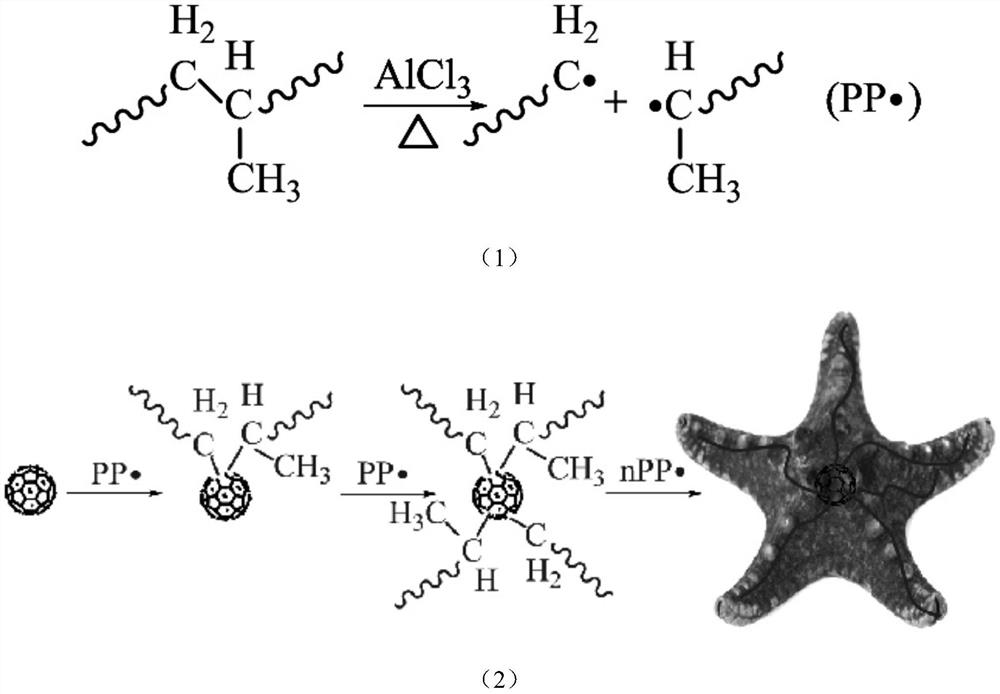

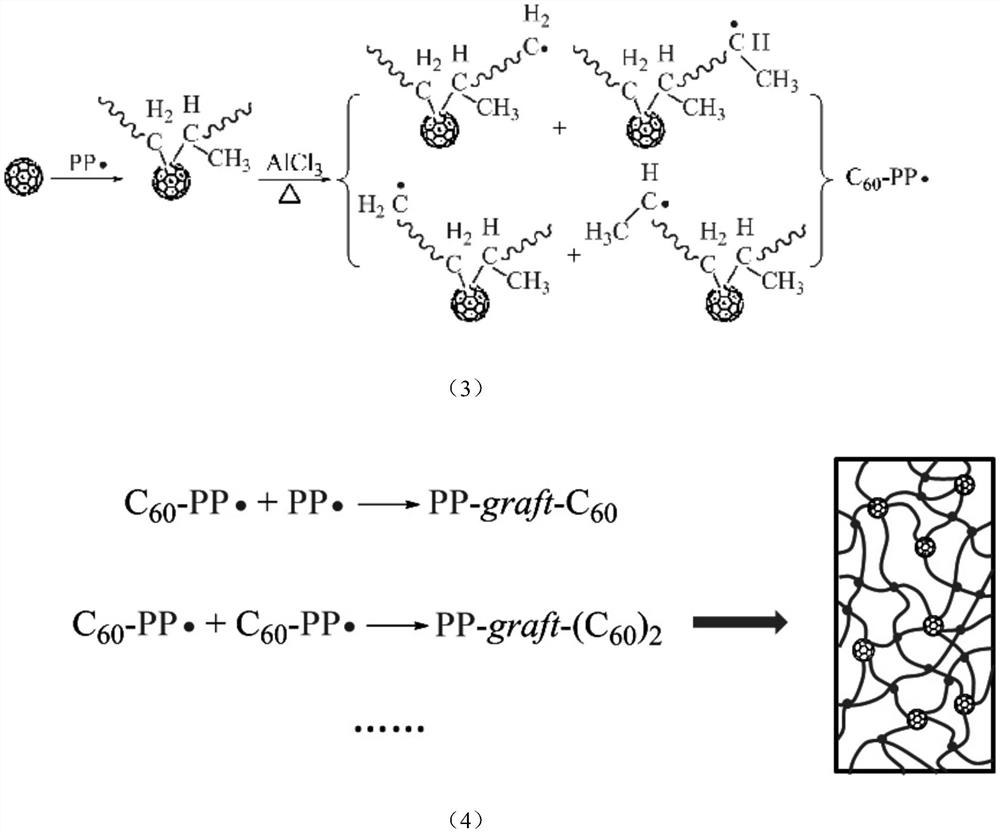

[0024] Lewis acid catalyzes the formation of macromolecular free radicals from the long chains of PP macromolecules, as shown in the following formula 1, and the macromolecular segments are grafted to the C 60 on the sphere. C 60 Known as "free radical sponge", each C 60 The spheres have numerous "reaction sites" where free radical addition can occur. The macromolecular chains are grafted to the C by radical addition reaction 60 sphere, formed with C 60 The c...

Embodiment 2

[0032] First, high-density polyethylene (HDPE) weighed 49.1g, C 60 Weigh 0.8g, yttrium trifluoromethanesulfonate (trifluoromethanesulfonate yttrium, CAS NO: 52093-30-8, Yb(OTf) 3 )) Weigh 0.3g, put them into a blast drying oven and dry at 100°C for 12h; then put the dried raw materials into a torque rheometer for melt blending, and record the torque data, blending temperature HDPE / C60 / Yb(OTf)3) composite material was prepared at 160°C, rotating speed 60r / min, and blending time 10min. Its reaction mechanism, sample preparation method and test method are with embodiment 1.

Embodiment 3

[0036] First, linear low density polyethylene (LLDPE) weighed 48.85g, C 70 Weigh 0.6g, cerium trifluoromethanesulfonate (Ce(OTf) 3 ) weighed 0.35g, put them into a blast drying oven and dried at 80°C for 24h; then put the dried raw materials into a torque rheometer for melt blending, and recorded the torque data, the blending temperature was 170 ℃, rotating speed 80r / min, blending time 10min, prepared LLDPE / C 70 / Ce(OTf) 3 composite material. Its reaction mechanism, sample preparation method and test method are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com