Application of rhodococcus pyridinovorans to anaerobic fermentation methanol production

A technology of Rhodococcus pyridinephilus and anaerobic fermentation, which is applied in the application field of Rhodococcus pyridinephilus in anaerobic fermentation of methane, can solve problems that have not yet been discovered, and achieve improved biogas production, a wide spectrum of electron donors, and easy The effect of cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Verification of the performance of Rhodococcus pyridineophilus in promoting anaerobic fermentation to produce methane

[0023] (1) Construct a small-scale test system of anaerobic fermentation producing methane:

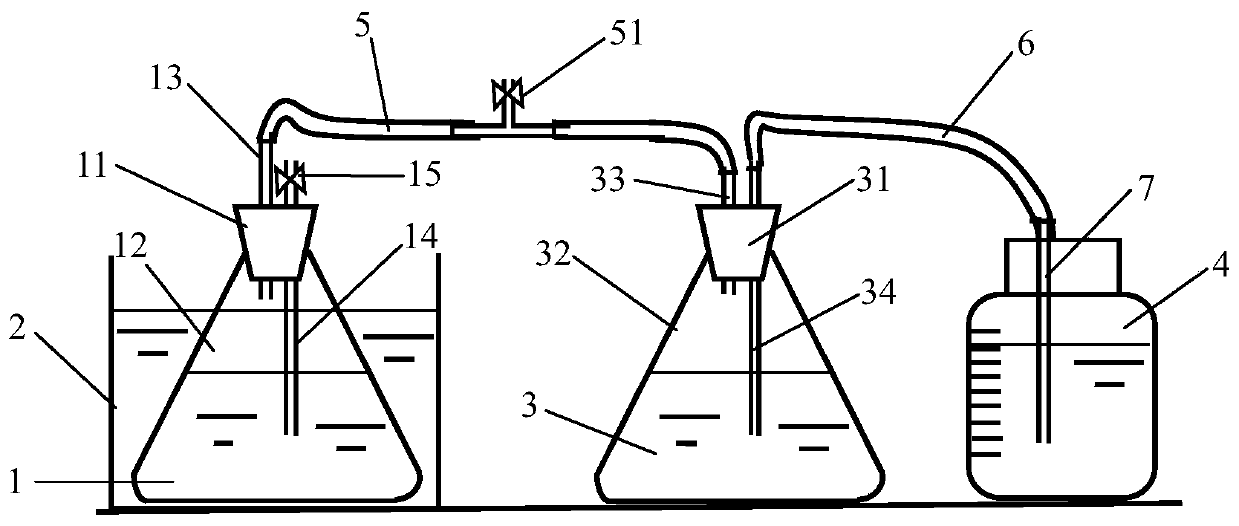

[0024] Such as figure 1 As shown, the small test system for producing methane by anaerobic fermentation of the present invention includes an anaerobic fermentation reaction device 1 , a constant temperature control device 2 , a gas collection device 3 and a measuring device 4 . The anaerobic fermentation reaction device 1 comprises the first conical flask 12 sealed with the first rubber stopper 11, the first conical flask 12 is a 2000mL conical flask, the first rubber stopper 11 is provided with an exhaust pipe 13 and a sample feeding pipe 14, and The sample feeding end of the sample tube 14 is provided with a first valve 15 . The constant temperature control device 2 is a constant temperature water tank, and the anaerobic fermentation reaction de...

Embodiment 2

[0034] Concrete operation process is identical with embodiment 1, and difference is:

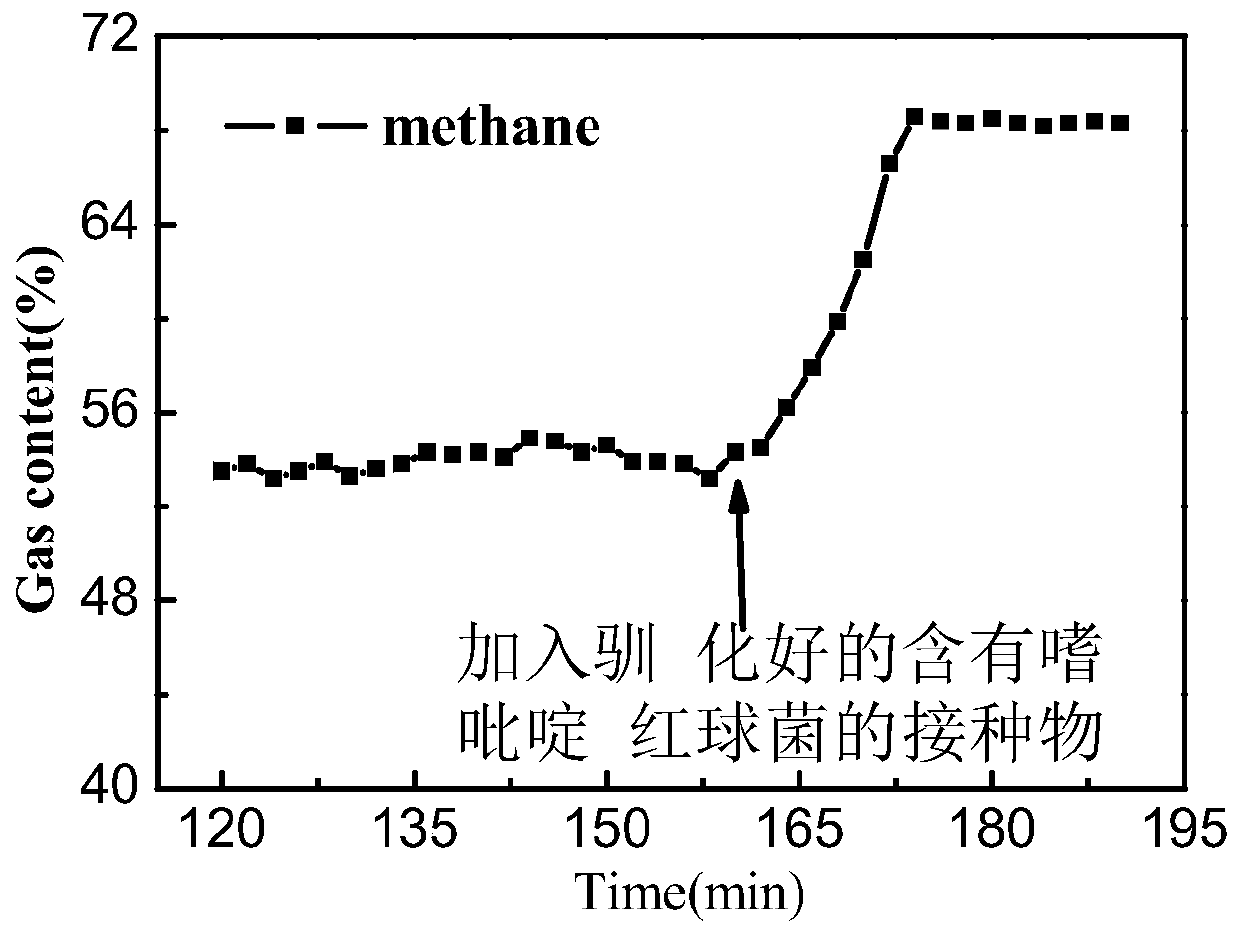

[0035] The raw material in the small-scale test system for anaerobic fermentation methane production is chicken manure. The original biogas production of anaerobic fermentation of chicken manure was 320-350mL / g·VS, and the methane content in the generated biogas was about 57.3%. After the inoculum of Rhodococcus pyridineophilus, the gas production of biogas increased to 420±30mL / g VS, while the methane content in the biogas increased to 73.1%, as image 3 .

Embodiment 3

[0037] Concrete operation process is identical with embodiment 1, and difference is:

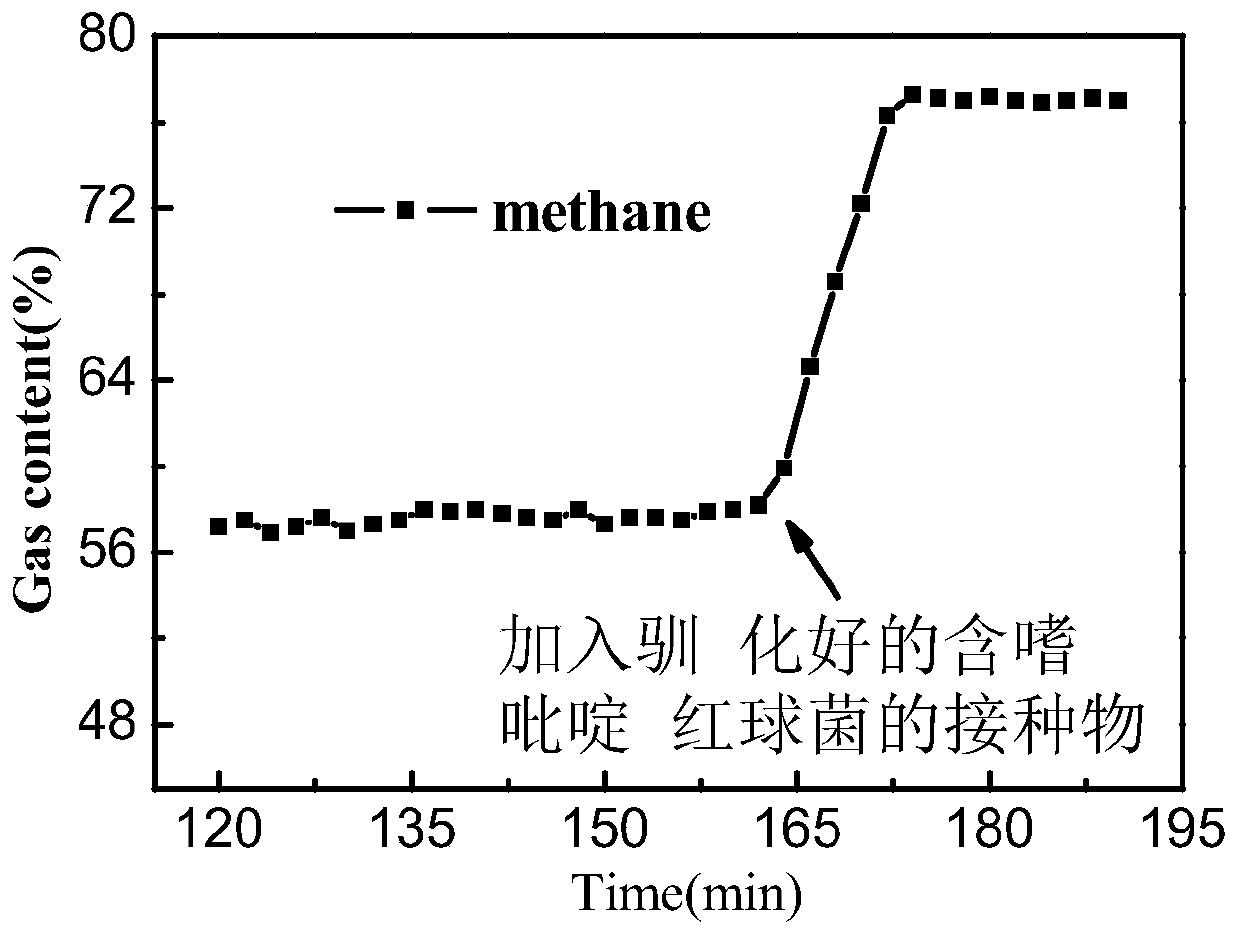

[0038] The raw material in the small test system of anaerobic fermentation methane production is kitchen waste. The original biogas production of anaerobic fermentation of kitchen waste was 230-250mL / g·VS, and the methane content in the generated biogas was about 48.3%. After a good inoculum containing Rhodococcus pyridineophilus, the gas production of biogas increased to 320±30mL / g VS, and the methane content in biogas increased to 67.3%, as Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com