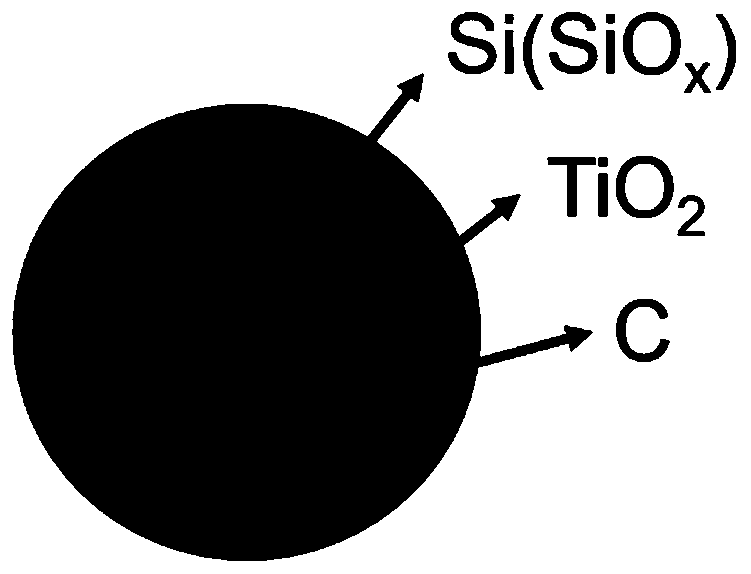

Silicon/silicon oxide-titanium dioxide-carbon core-shell structure composite particle and preparation thereof

A technology of composite particles and silicon oxide, which is applied in the direction of structural parts, secondary batteries, electrochemical generators, etc., can solve problems such as difficulty in ensuring coating uniformity, and achieve easy batch preparation, high specific capacity, uniform and dense crystallization degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] 100gSiO x The powder is placed in the fluidized bed reactor, with 600h -1 The space velocity of the Ar gas is introduced to make the powder in a fully fluidized state, and then the temperature is raised to 1200°C at a rate of 15°C / min; the TiCl carried by Ar is 4 steam and water vapor with TiCl 4 :H 2 The ratio of O=1:6 is respectively introduced into the fluidized bed for deposition reaction, in which TiCl 4 :Ar=1:5,H 2 O:Ar=1:10, the total space velocity of the two gases is 600h -1 . Stop feeding TiCl after 40min 4 steam and water vapor, naturally cooled to room temperature, the intermediate product SiO x @TiO 2 .

[0074] The intermediate product SiO x @TiO 2 Placed in a fluidized bed reactor for 600h -1 Inject Ar gas at a space velocity to keep the powder in a fully fluidized state, and then raise the temperature to 850°C at a rate of 10°C / min; 2 h 4 The gas is introduced into the fluidized bed for deposition reaction, where C 2 h 4 :Ar=1:6, the tota...

Embodiment 2

[0081] 100gSiO x The powder is placed in the fluidized bed reactor, with 200h -1 The space velocity of the Ar gas is introduced to make the powder in a fully fluidized state, and then the temperature is raised to 1000°C at a rate of 5°C / min; the TiCl carried by Ar is 4 steam and water vapor with TiCl 4 :H 2 The ratio of O=1:2 is respectively introduced into the fluidized bed for deposition reaction, in which TiCl 4 :Ar=1:1,H 2 O: Ar = 1: 2, the total space velocity of the two gases is 200h -1 . Stop feeding TiCl after 10min 4 steam and water vapor, naturally cooled to room temperature, the intermediate product SiO x @TiO 2 .

[0082] The intermediate product SiO x @TiO 2 Placed in a fluidized bed reactor for 200h -1 The space velocity of the Ar gas is introduced to make the powder in a fully fluidized state, and then the temperature is raised to 700°C at a rate of 5°C / min; the C carried by Ar is 3 h 6 The gas is introduced into the fluidized bed for deposition re...

Embodiment 3

[0084] 100gSiO x The powder is placed in the fluidized bed reactor, with 1000h -1 The space velocity of the Ar gas is introduced to make the powder in a fully fluidized state, and then the temperature is raised to 1400°C at a rate of 15°C / min; the TiCl carried by Ar is 4 steam and water vapor with TiCl 4 :H 2 The ratio of O=1:10 is respectively introduced into the fluidized bed for deposition reaction, in which TiCl 4 :Ar=1:10,H 2 O:Ar=1:20, the total space velocity of the two gases is 1000h -1 . Stop feeding TiCl after 60min 4 steam and water vapor, naturally cooled to room temperature, the intermediate product SiO x @TiO 2 .

[0085]The intermediate product SiO x @TiO 2 placed in a fluidized bed reactor for 1000h -1 Inject Ar gas at a space velocity to keep the powder in a fully fluidized state, and then raise the temperature to 1000°C at a rate of 15°C / min; 2 h 2 The gas is introduced into the fluidized bed for deposition reaction, where C 2 h 2 :Ar=1:10, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com