Covalent organic framework IISERP-COOH-COF1 membrane and preparation method and application

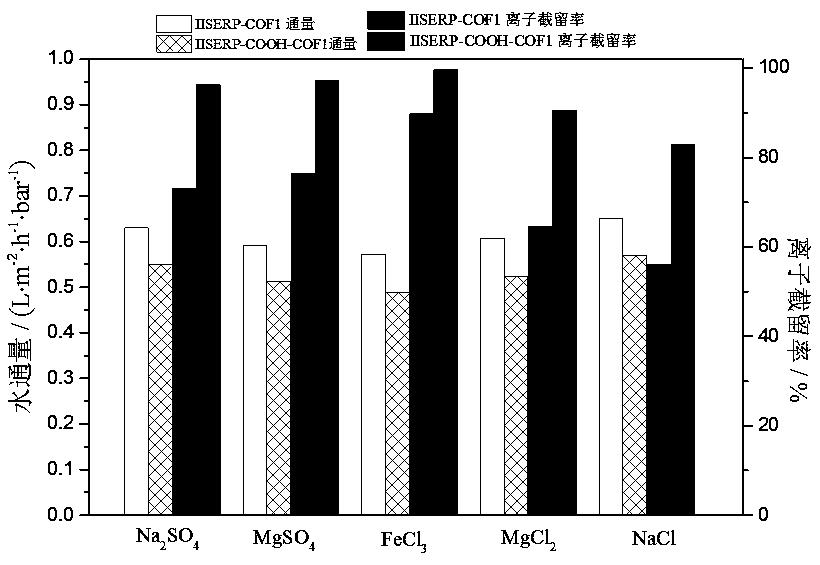

A technology of IISERP-COOH-COF1 and IISERP-COF1, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of low ion retention rate, achieve good application prospects and high film repeatability , The effect of excellent seawater desalination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

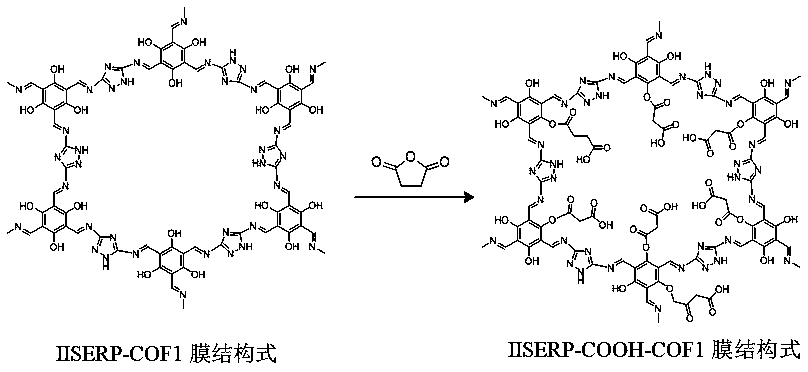

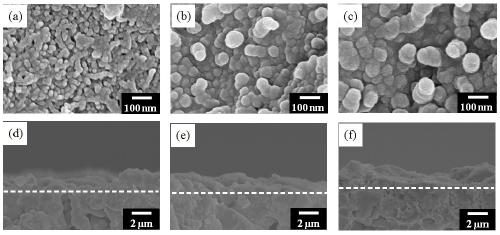

[0048] Example 1 Covalent Organic Framework Film IISERP-COOH-COF1

[0049] Step 1: APTES functionalized porous tubular alumina support

[0050] The alumina ceramic tube adopted in the present invention has an outer diameter of 10 mm, an inner diameter of 6 mm, an inner diameter of 8 mm, a pore diameter of 0.5 μm, and a porosity of 25%.

[0051] APTES functionally modifies the porous carrier, modifying a layer of amino groups on the surface of the carrier, 3ml of APTES (3-aminopropyltriethoxysilane), 60ml of toluene, put the alumina ceramic tube into the prepared above Solution, hydrothermal reaction at 110°C for 90 minutes.

[0052] Step 2: Preparation of covalent organic framework seed layer by in situ seeding method

[0053] The IISERP-COF1 seed layer was prepared on the surface of APTES-modified alumina ceramic tube by in-situ growth method, and the seed layer was introduced. Specifically, 80 mg of phloroglucinol trialdehyde, 40 mg of 2,5-diaminotriazole, 10 ml of N,N-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com