Diamond wire saw saw-cutting machining performance evaluating testing machine

A diamond wire saw and processing performance technology, applied in the field of testing machines, can solve the problems of large size, complex structure and high cost, and achieve the effect of eliminating tension control mechanism, small overall volume and simplified control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

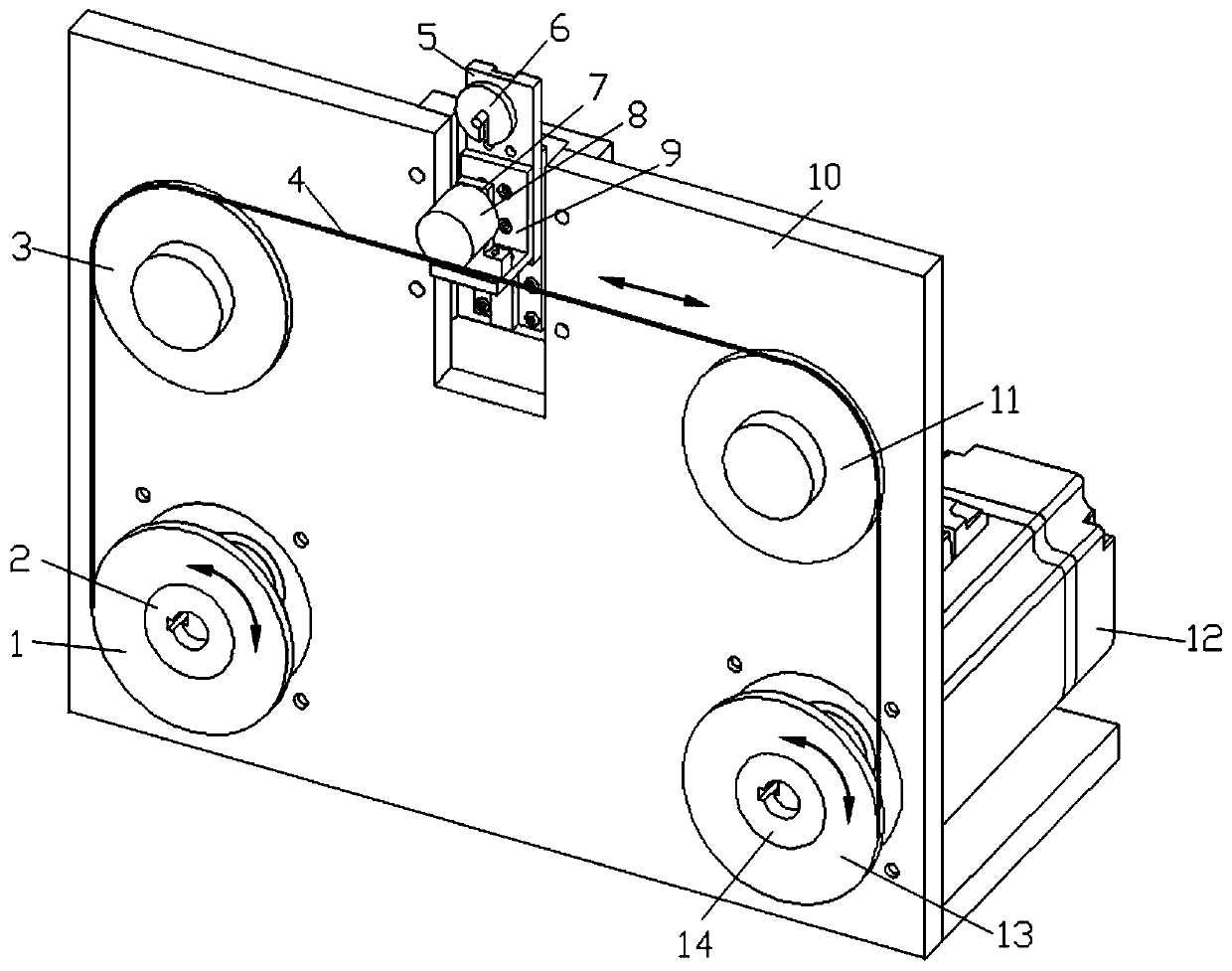

[0024] Diamond wire saw sawing performance evaluation test machine of the present invention is used for diamond wire saw sawing performance evaluation test, its overall structure is as follows figure 1 As shown, it includes a frame 10, a constant force feeding unit, a sawing processing unit and a control unit. The constant force feeding unit, the sawing processing unit and the control unit are all arranged on the frame 10 .

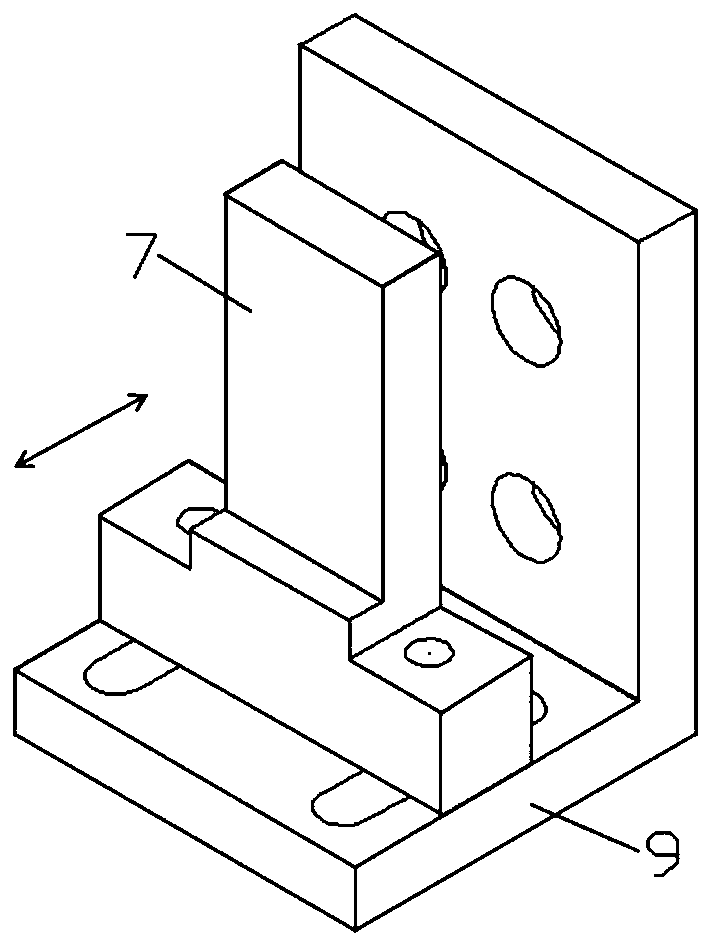

[0025] The constant force feeding unit includes a rolling guide rail 5 , an object stage 7 , a working table 9 and a weight 6 . The structure of stage 7 is as figure 2 As shown, a long hole is provided on it, and the workbench 9 is installed and fixed on the stage 7 through the bolt inserted into the long hole, so that the stage 7 is installed on the workbench 9 and its position can be adjusted, and the workpiece 8 is fixed. It is installed on the stage 7 to realize the adjustment of slice thickness. The workbench 9 is fixedly installed on the rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com