Production method of large-particle cobalt carbonate for high-voltage lithium cobaltate

A production method and technology for large particles, applied in cobalt carbonate and other directions, can solve problems such as poor morphology, poor stability, and wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

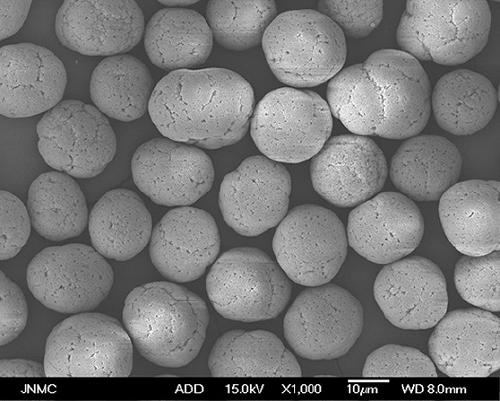

Image

Examples

Embodiment 1

[0025] A method for producing large-particle cobalt carbonate for high-voltage lithium cobalt oxide, the method comprising a nucleus growth process, a particle growth process, and an aging process, wherein the nucleus growth process is to nucleate reaction raw materials in a crystal nucleus generation kettle, The pH value is 8.5; the particle growth process includes a particle primary growth process and a particle optimization growth process. The particle primary growth process is carried out in the primary reactor, and the particle optimization growth process is carried out in the optimization reactor. The pH value of the growth process is within the scope of 8.0; the aging process is carried out in the aging kettle;

[0026] Specifically include the following steps:

[0027] (1) 60g / L of cobalt chloride metal liquid and 160g / L of ammonium bicarbonate solution were added to the ammonium bicarbonate solution containing 160g / L of ammonium bicarbonate through a metering pump at ...

Embodiment 2

[0033] A method for producing large-particle cobalt carbonate for high-voltage lithium cobalt oxide, the method comprising a nucleus growth process, a particle growth process, and an aging process, wherein the nucleus growth process is to nucleate reaction raw materials in a crystal nucleus generation kettle, The pH is 6.8; the particle growth process includes a particle primary growth process and a particle optimized growth process. The particle primary growth process is performed in the primary reactor, and the particle optimized growth process is performed in the optimized reactor. The pH value of operation is 6.8; Described ageing operation is carried out in ageing kettle;

[0034] Specifically include the following steps:

[0035] (1) 105g / L of cobalt chloride metal liquid and 200g / L of ammonium bicarbonate solution were added to the solution containing 240g / L of ammonium bicarbonate through a metering pump according to the flow rates of 450L / h and 550L / h, respectively. ...

Embodiment 3

[0041] A method for producing large-particle cobalt carbonate for high-voltage lithium cobalt oxide,

[0042] The method includes a nucleus growth process, a particle growth process, and an aging process. The nucleus growth process is to nucleate the reaction raw materials in a crystal nucleus generation kettle, and the pH value is 7; the particle growth process includes a particle primary growth process, a particle growth process, and a The optimized growth process, the particle primary growth process is performed in the primary reactor, the particle optimized growth process is performed in the optimized reactor, and the pH values of the particle primary growth process and the particle optimized growth process are both controlled at 7; the aging process is in In the aging kettle;

[0043] Include the following steps:

[0044] (1) 150g / L of cobalt chloride metal liquid and 240g / L of ammonium bicarbonate solution were added to the solution containing 180g / L of ammonium bicar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com