Device and technology for processing wastewater generated in fastener surface treatment

A surface treatment and treatment device technology, which is applied in general water supply conservation, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of non-reusability and low purity of solid salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

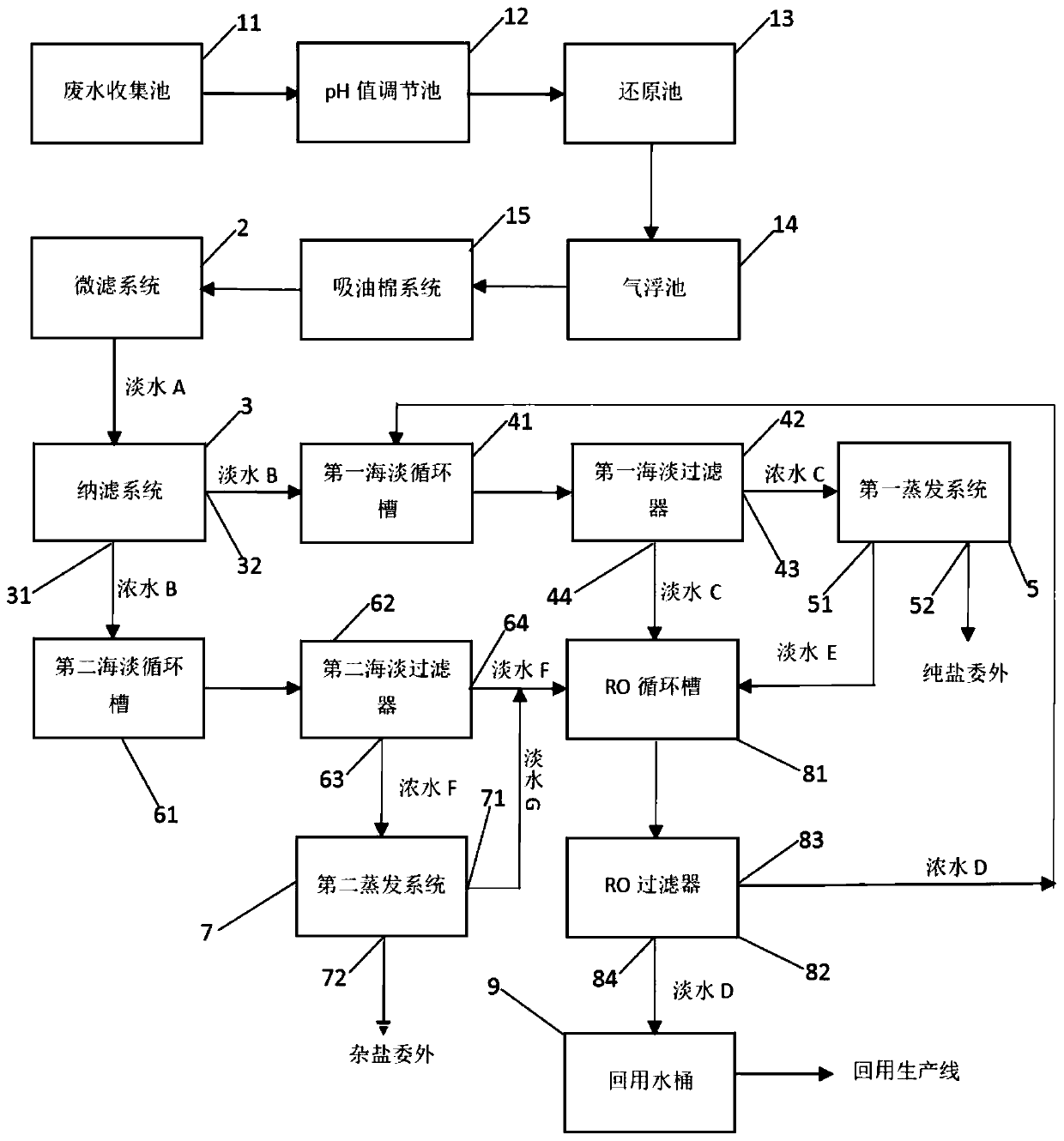

[0041] figure 1 It is a process flow diagram of a treatment device for fastener surface treatment wastewater provided in Example 1 of the present invention. see figure 1 , Embodiment 1 of the present invention provides a treatment device for treating wastewater on the surface of fasteners, including: a pretreatment system, a microfiltration system 2, a nanofiltration system 3, a first desalination system, a first evaporation system 5, and a second seawater desalination system. Dilute system, second evaporation system 7 and RO system. The pretreatment system, the microfiltration system 2 and the nanofiltration system 3 are connected in sequence.

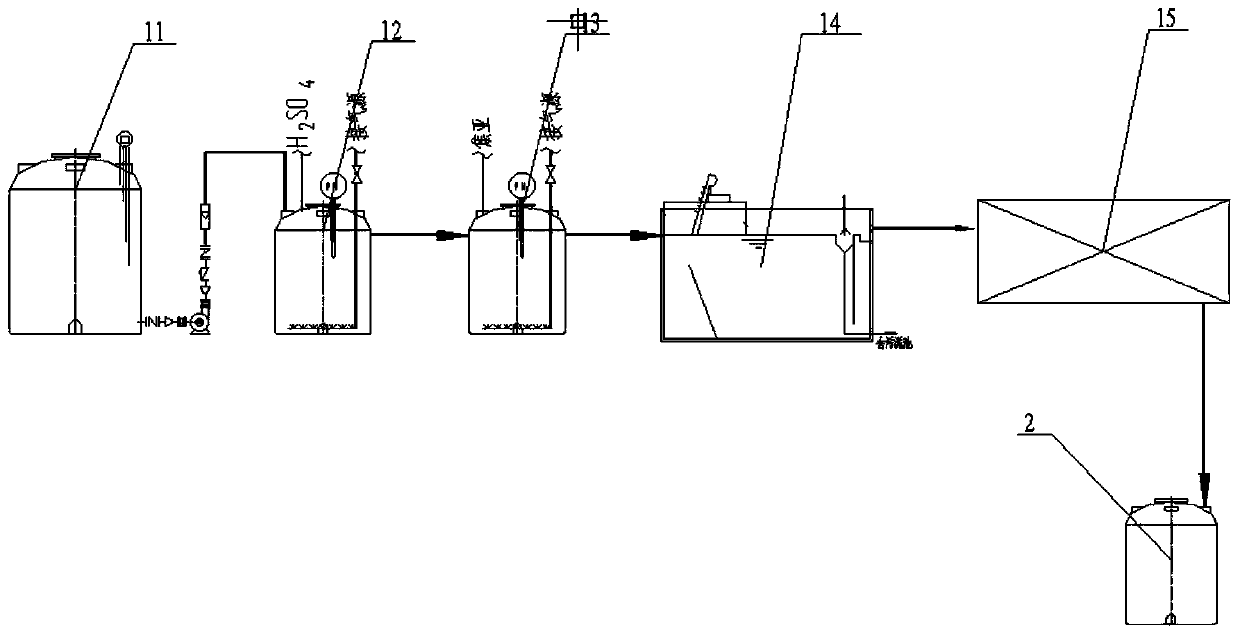

[0042] figure 2 yes figure 1 The structural block diagram of the pretreatment system and the microfiltration system 2 of the treatment device for treating wastewater on the surface of fasteners shown. see figure 2 , the pretreatment system includes a wastewater collection tank 11, a pH value adjustment tank 12, a reduction tan...

Embodiment 2

[0061] Embodiment 2 of the present invention provides a process for treating fastener surface treatment wastewater using the treatment device described in Embodiment 1, comprising the following steps:

[0062] S1. The fastener surface treatment wastewater is collected in the wastewater collection pool 11. The wastewater first enters the pH adjustment pool 12 for acid adjustment, then enters the reduction pool 13 for reduction treatment, and then enters the air flotation pool 14 for solid-liquid separation treatment. Finally enter the oil-absorbing cotton system 15 to remove oil stains;

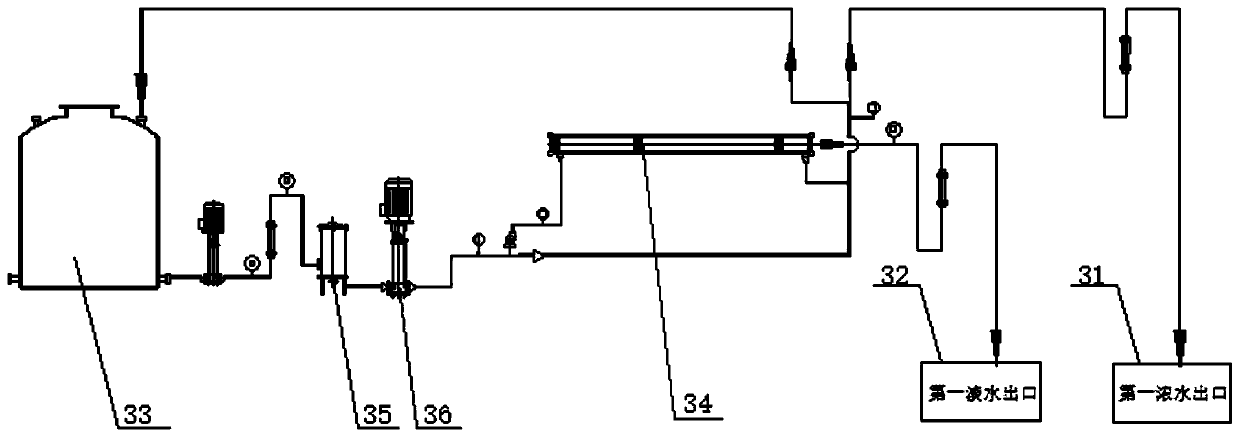

[0063] S2. Start the microfiltration system 2, so that the wastewater treated by S1 enters the microfiltration system 2 for cross-flow filtration to obtain fresh water A, which enters the nanofiltration system 3 and obtains fresh water B and concentrated water B, and fresh water B is obtained from the first fresh water The outlet 32 flows out, and the concentrated water B flows out from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com