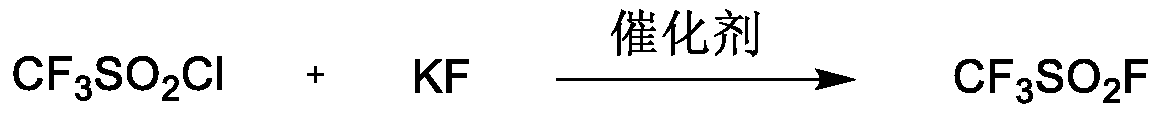

Method for preparing trifluoromethylsulfonyl fluoride from trifluoromethylsulfonyl chloride

A technology of trifluoromethanesulfonyl chloride and trifluoromethanesulfonyl, applied in the field of organic chemical industry, to achieve the effects of improving reaction speed and production efficiency, simple synthesis route, and high fault tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

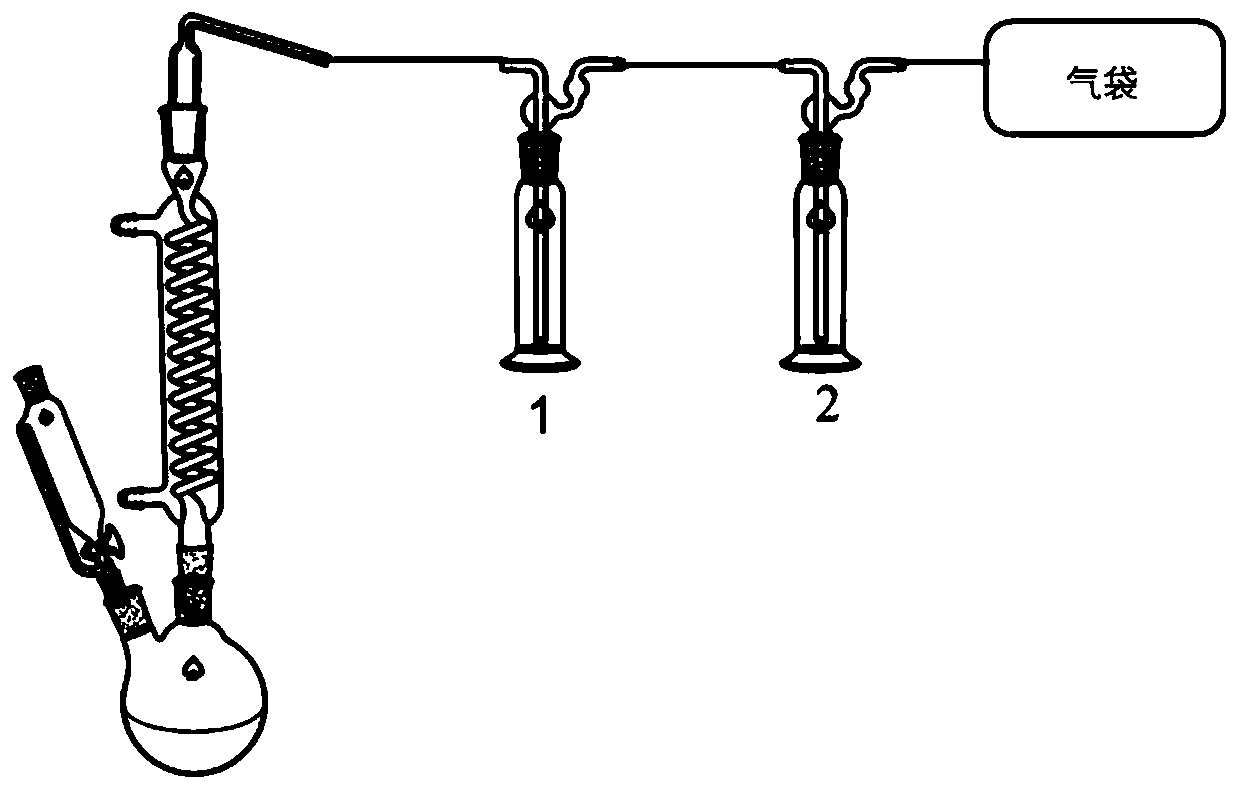

Image

Examples

Embodiment 1

[0038] 10 g of potassium fluoride and 0.1 g of 18-crown-6 were added to 30 mL of anhydrous acetonitrile solution, 10 g of trifluoromethanesulfonyl chloride was added dropwise to the solution, and the solution was placed in an ice-water bath with the temperature kept at 0°C. After the dropwise addition was completed, it was kept for 2 hours. After the reaction was finished, 3.48 g of trifluoromethanesulfonyl fluoride could be collected in No. 2 cold trap, with a yield of 40% and a purity of 94.0%.

Embodiment 2

[0040] 100 g of potassium fluoride and 5 g of 18-crown-6 were added to 400 mL of anhydrous acetonitrile solution, 100 g of trifluoromethanesulfonyl chloride was added dropwise to the solution, and the solution was placed in an ice-water bath with the temperature kept at 0°C. After the dropwise addition was completed, it was kept for 2 hours. After the reaction was finished, 56.55 g of trifluoromethanesulfonyl fluoride could be collected in No. 2 cold trap, with a yield of 65% and a purity of 98.4%.

Embodiment 3

[0042] Add 50 g of potassium fluoride and 1.25 g of 18-crown-6 into 200 mL of anhydrous acetonitrile solution, add 50 g of trifluoromethanesulfonyl chloride dropwise into the solution, and place the solution in an ice-water bath with the temperature kept at 0°C. After the dropwise addition was completed, it was kept for 2 hours. After the reaction was finished, 28.00 g of trifluoromethanesulfonyl fluoride could be collected in No. 2 cold trap, with a yield of 64% and a purity of 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com