Method for producing PVC resin and obtained resin

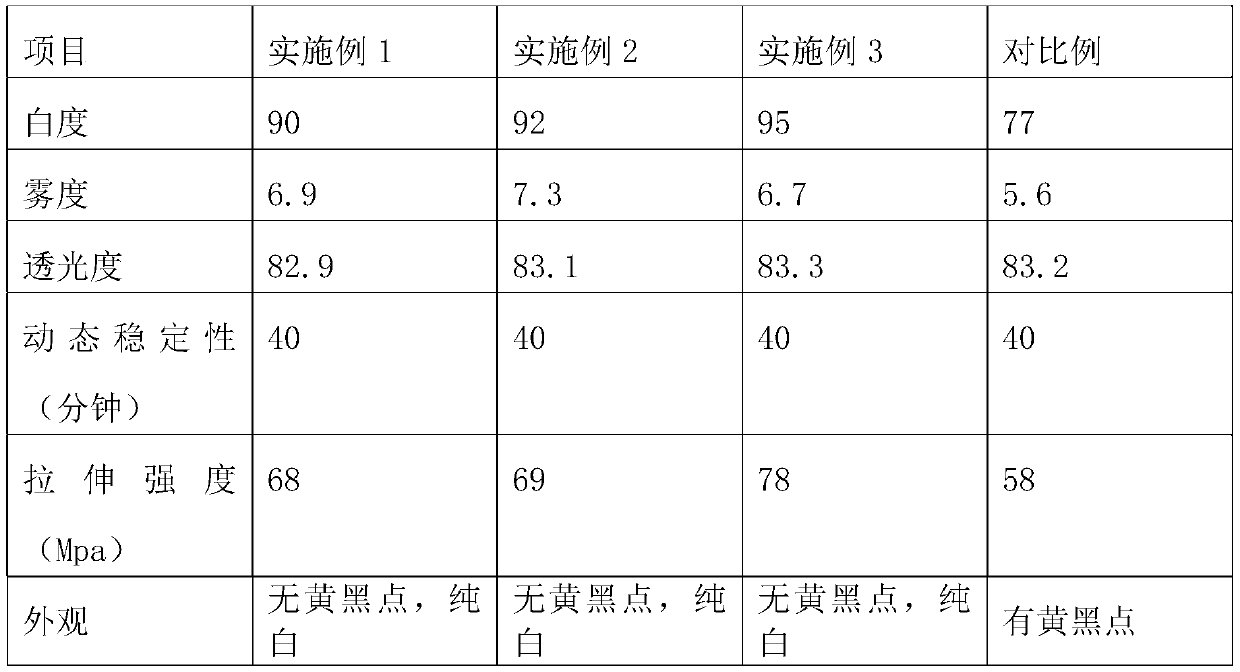

A PVC resin and production method technology, applied in the field of organic chemistry, can solve the problems of long-term use performance, physical and mechanical performance degradation, stability, and poor whiteness of PVC, and achieve high anti-aging performance, reduced black and yellow spots, The effect of little change in light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of production method of PVC resin, adopts suspension polymerization production process, described production method comprises operation:

[0036] Rare earth additives, vinyl chloride (VCM) monomers, and ion-free water are sequentially added into the polymerization kettle, wherein the rare earth additives are lanthanum stearate, and the mass of lanthanum stearate is 0.035% of VCM. delay 120s;

[0037] After adding the configured quantitative dispersant, initiator and other auxiliary agents, the polymerization kettle enters the reaction stage. Initiator: EHP and CNP (mass ratio 1:3), the total dosage is 8 / 10,000 of the monomer mass.

[0038] Dispersant 2: 25 parts of GH-20 (polyvinyl alcohol)

[0039] Dispersant 1: 80 parts of 7206 (polyvinyl alcohol)

[0040] HG-02 (polyvinyl alcohol) 10 parts

[0041] 60HD50 (hydroxypropyl methylcellulose) 10 parts

[0042] The total amount of dispersant is 8 / 10,000 of the monomer mass.

[0043] The reaction process is contr...

Embodiment 2

[0045] The production method of this embodiment is basically the same as that of Example 1, except that the rare earth auxiliary agent lanthanum stearate is added in the production process, and the quality of lanthanum stearate is 0.046% of VCM.

Embodiment 3

[0047] The production method of this embodiment is basically the same as that of Example 1, except that the rare earth additive lanthanum stearate is added in the production process, and the quality of lanthanum stearate is 0.073% of VCM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com