Thermoplastic polyurethane elastomer, and preparation method and application thereof

A thermoplastic polyurethane and elastomer technology, which is applied in the field of chemical material synthesis, can solve the problems of detachment and pollution, and achieve the effects of easy acquisition, odor removal and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

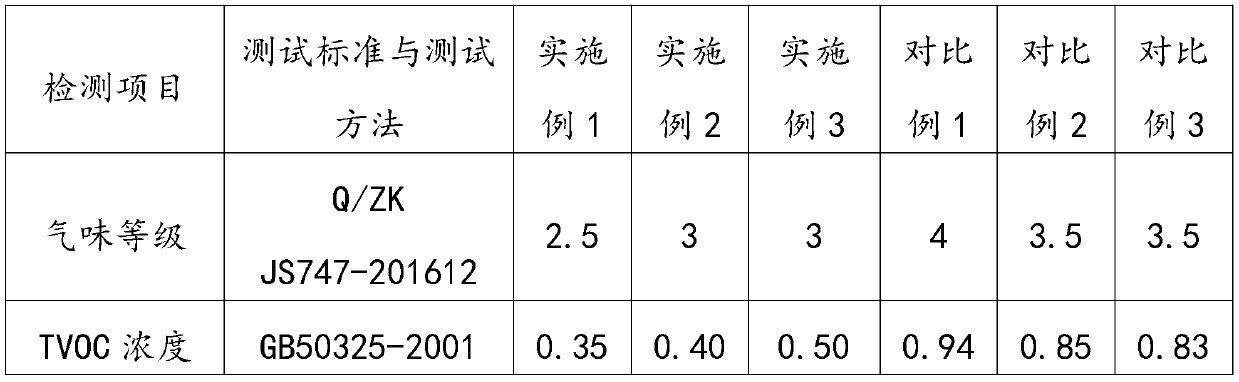

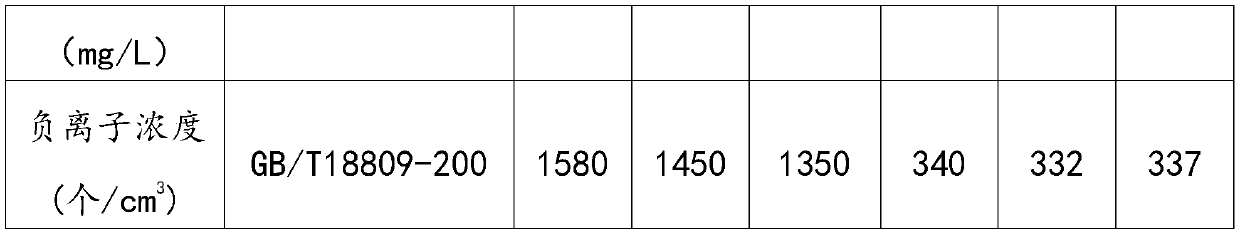

Examples

Embodiment 1

[0025] A thermoplastic polyurethane elastomer material made of the following raw materials: 5600g of polytetrahydrofuran diol (PTMG) with a molecular weight of 1000g / mol, 794g of 1,4-butanediol (BDO), 3606g of diphenylmethane diisocyanate (MDI ), 1000g tourmaline with a particle size of 1μm, 800g wizard stone with a particle size of 1μm, 200g vinyl trichlorosilane, 150g tetrakis (4-hydroxy 3,5-tert-butylphenyl propionate) pentaerythritol ester, 50g tri (2.4-Di-tert-butylphenyl)phosphite.

[0026] The preparation method of above-mentioned thermoplastic polyurethane elastomer material, comprises the steps:

[0027] 1) 5600g of PTMG, 1000g tourmaline, 800g wizard stone, 200g vinyl trichlorosilane, 150g tetrakis (4-hydroxy 3,5-tert-butylphenyl propionate) pentaerythritol ester, 50g tris (2.4-di-tert Butyl phenyl) phosphite is added in the container with heating function, use ultrasonic instrument and high-speed mechanical stirring device to ultrasonic, stir and mix, obtain system...

Embodiment 2

[0031] A thermoplastic polyurethane elastomer material consisting of the following raw materials: 5900g polyester polyol (PE20) with a molecular weight of 2000g / mol, 873g 1,4-butanediol (BDO), 3227g diphenylmethane diisocyanate (MDI) , 500g tourmaline with a particle size of 50μm, 400g wizard stone with a particle size of 50μm, 100g vinyltrimethoxysilane, 150g tetrakis (4-hydroxy 3,5-tert-butylphenylpropionate) pentaerythritol ester, 50g tri (2.4-Di-tert-butylphenyl)phosphite.

[0032] The preparation method of above-mentioned thermoplastic polyurethane elastomer material, comprises the steps:

[0033] 1) Mix 590g PE20, 500g tourmaline, 400g wizard stone, 100g vinyltrimethoxysilane, 150g tetrakis (4-hydroxy 3,5-tert-butylphenyl propionate) pentaerythritol ester and 50g tris(2.4-di-tert Butyl phenyl) phosphite is added in the container with heating function, use ultrasonic instrument and high-speed mechanical stirring device to ultrasonic, stir and mix, obtain system A;

[00...

Embodiment 3

[0037] A thermoplastic polyurethane elastomer material consisting of the following raw materials: 5600g of polyester polyol (PE20) with a molecular weight of 2000g / mol, 638g of ethylene glycol (EDO), 3438g of diphenylmethane diisocyanate (MDI), 100g of particle size 100μm tourmaline, 100g wizard stone with a particle size of 100μm, 100g 3-isocyanate propyltriethoxysilane, 200g tetrakis (4-hydroxy 3,5-tert-butylphenyl propionate) pentaerythritol ester, 50g tri (2.4-Di-tert-butylphenyl)phosphite.

[0038] The preparation method of above-mentioned thermoplastic polyurethane elastomer material, comprises the steps:

[0039] 1) 5600g PE20, 100g tourmaline, 100g wizard stone, 100g 3-isocyanate propyltriethoxysilane, 200g tetrakis (4-hydroxy 3,5-tert-butylphenyl propionate) pentaerythritol ester and 50g tri( 2. Add 4-di-tert-butylphenyl)phosphite into a container with a heating function, use an ultrasonic instrument and a high-speed mechanical stirring device to ultrasonically, stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com