A kind of production technology of high amylose/polylactic acid composite material masterbatch method

A technology of high amylose and composite materials, which is applied in the production process of high amylose/polylactic acid composite materials, can solve the problems of high evaporation residue, difficulty in granulating the production masterbatch, and increased number of products, so as to achieve stable and reliable process flow and suitable for large-scale production. Effects of mass production and improved tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

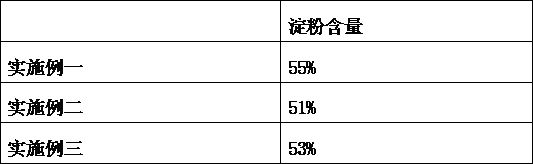

Examples

Embodiment Construction

[0030] The following is Embodiment 1 of the present invention.

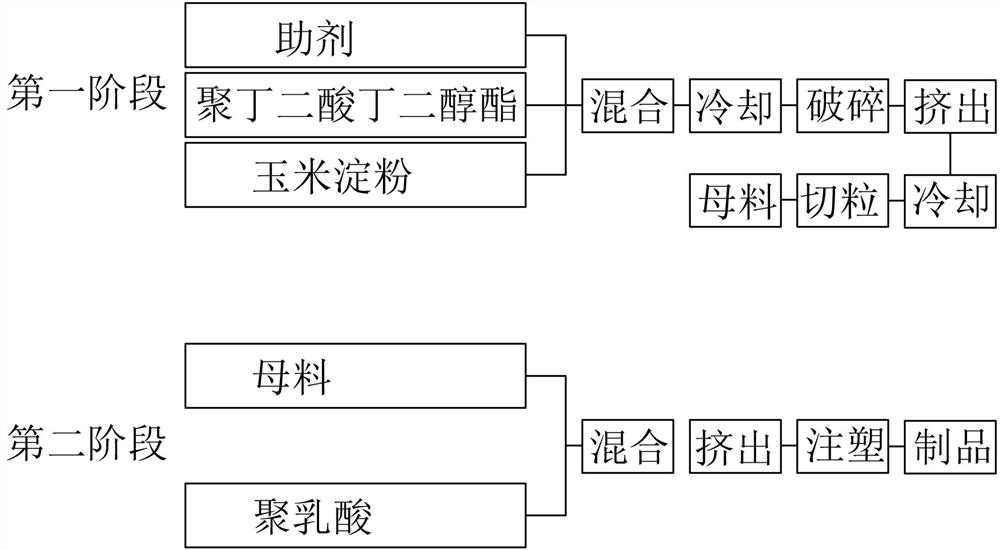

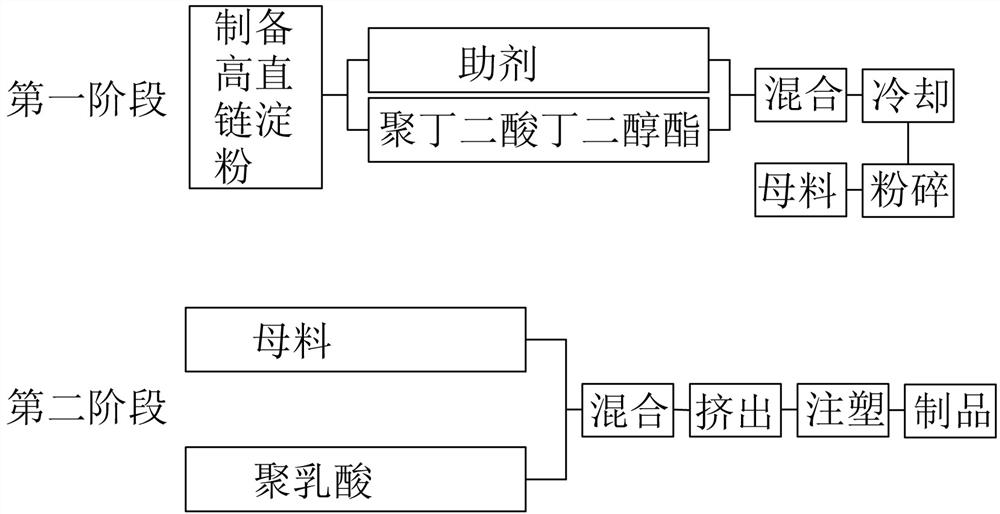

[0031] A high amylose / polylactic acid composite material master batch method production process, comprising the following steps:

[0032] The first step, prepare the masterbatch

[0033] (1.1) According to the weight ratio, select 90 parts of food-grade corn starch, 20 parts of polybutylene succinate, 1 part of maleic anhydride, and 3 parts of additives, and weigh them for later use;

[0034] (1.2) Select a high-speed mixing unit with a capacity of 800 liters, set the heating temperature of the high-speed mixing unit to 120°C, and the rotation speed of the stirring paddle to 900r / min, and start the mixing paddle from low to high. High-speed mixing unit;

[0035] (1.3) Put the above weight portion of cornstarch into the reactor of the high-speed mixing unit, and sequentially add 1 part of pullulanase and 1 part of n-butanol into the reactor to make the cornstarch, pullulanase , n-butanol is fully reacted to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com