Metal target used for electrochromic glass and preparation method and application method thereof

A technology of electrochromic glass and metal targets, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as inapplicability to large-scale production, affecting production efficiency, slow discoloration speed, etc., to achieve Fast film forming speed, high production efficiency and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

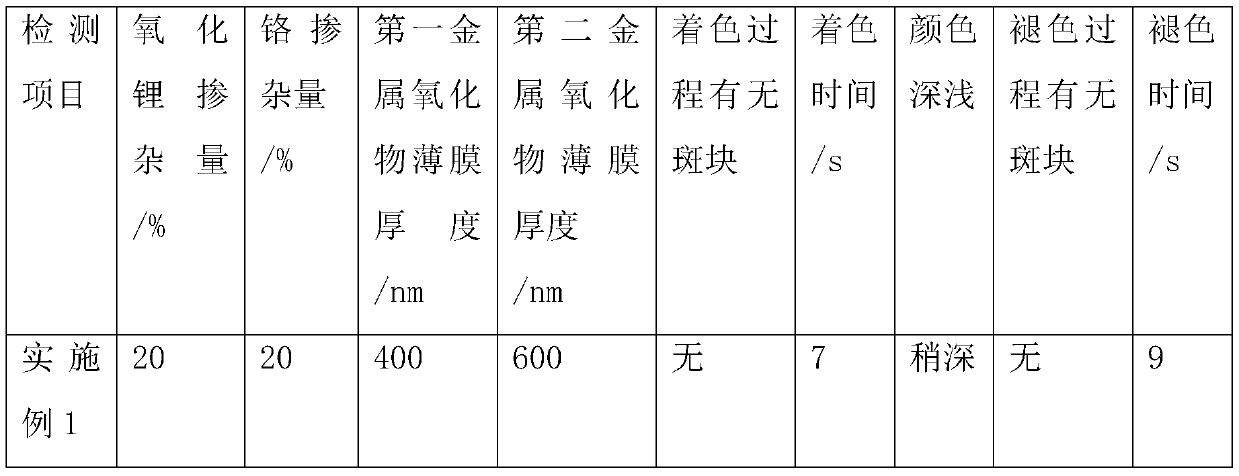

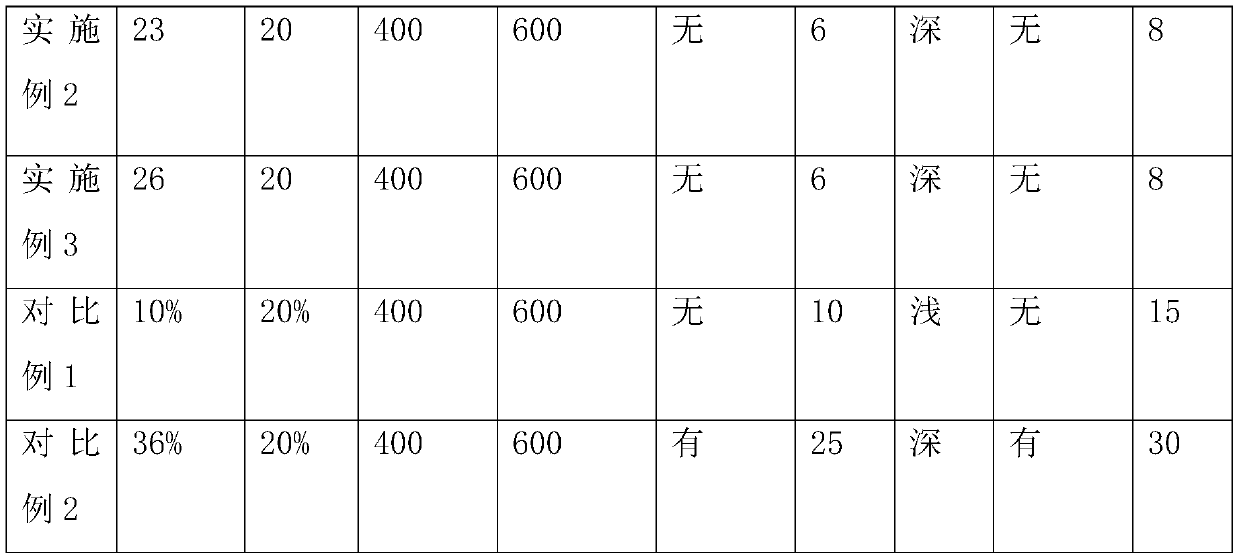

Embodiment 1

[0038] Example 1: A metal target for electrochromic glass, including a first metal target and a second metal target, the first metal target is tungsten powder, and the particle size of the tungsten powder is less than or equal to 40 μm. The two-metal target includes nickel powder, chromium powder and lithium oxide powder with a mass ratio of 1:0.2:0.2. The particle size of nickel powder and chromium powder is 38μm, and the particle size of lithium oxide powder is 400nm;

[0039] The preparation method of the above-mentioned first metal target for electrochromic glass is as follows: the tungsten powder is made into a target by hot pressing, the hot pressing temperature is 1000°C, the hot pressing pressure is 20 MPa, and the holding time is 40 minutes;

[0040] The application method of the above-mentioned first metal target for electrochromic glass is as follows: use DC reactive magnetron sputtering to coat the first oxide film on the first transparent ITO conductive layer, the ...

Embodiment 2

[0043] Example 2: A metal target for electrochromic glass, including a first metal target and a second metal target, the first metal target is tungsten powder, the particle size of the tungsten powder is 40 μm, the second metal The target material includes nickel powder, chromium powder and lithium oxide powder with a mass ratio of 1:0.2:0.23. The particle size of nickel powder and chromium powder is 40 μm, and the particle size of lithium oxide powder is 400 nm;

[0044] The preparation method of the above-mentioned first metal target for electrochromic glass is as follows: the tungsten powder is made into a target by hot isostatic pressing, the hot isostatic pressing temperature is 1250° C., and the hot isostatic pressing pressure is 140 MPa. Pressure holding time 2.5h;

[0045] The application method of the above-mentioned first metal target for electrochromic glass is as follows: use DC reactive magnetron sputtering to coat the first oxide film on the first transparent ITO...

Embodiment 3

[0048] Example 3: A metal target for electrochromic glass, including a first metal target and a second metal target, the first metal target is tungsten powder, the particle size of the tungsten powder is 40 μm, the second metal The target material includes nickel powder, chromium powder and lithium oxide powder with a mass ratio of 1:0.2:0.26. The particle size of nickel powder and chromium powder is nickel powder with a particle size of 40 μm, and the particle size of lithium oxide powder is 400 nm;

[0049] The preparation method of the above-mentioned first metal target for electrochromic glass is as follows: the tungsten powder is made into a target by hot isostatic pressing, the hot pressing temperature is 800°C, the hot pressing pressure is 19 MPa, and the holding time is 35 minutes ;

[0050] The application method of the above-mentioned first metal target for electrochromic glass is as follows: use DC reactive magnetron sputtering to coat the first oxide film on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com