Vanadium pentoxide cathode material, preparation method and application thereof

A technology of vanadium pentoxide and cathode material, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of low lithium ion diffusion coefficient, poor cycle stability, unstable structure, etc. The effect of distance, maintaining stability, reducing transit time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] A vanadium pentoxide positive electrode material, the vanadium pentoxide positive electrode material is a three-dimensional nanoflower structure, the sheet thickness of the nanoflower is 10-100 nm, and a plurality of holes are distributed on the three-dimensional nanoflower, each The diameter of each hole is 1-50 μm.

[0026] Further, the vanadium content in the positive electrode material of vanadium pentoxide is 10-50wt%, preferably 20-30wt%, the carbon content is 10-50wt%, preferably 20-40wt%, and the rest is oxygen.

[0027] A preparation method of vanadium pentoxide cathode material, comprising the following steps:

[0028] Step 1, hydrothermally growing vanadium disulfide with a three-dimensional nanoflower structure on an inert conductive substrate;

[0029] Step 2: putting the conductive substrate of vanadium disulfide with three-dimensional nanoflower structure into an oxygen-containing atmosphere and annealing to obtain a positive electrode material of vanadi...

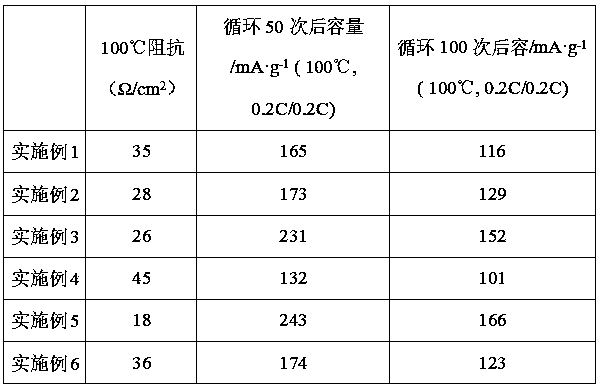

Embodiment 1

[0045] (1) Set the size to 2 cm 2 , the graphene paper with a thickness of 20 μm was placed in the precursor mixed aqueous solution A with a mass ratio of 1:1 thioacetamide and ammonium metavanadate, and hydrothermally reacted at 120°C for 12 h to obtain a three-dimensional nanoflower structure vanadium disulfide VS 2 , wherein the concentration of the mixed solution A is 30 g / L;

[0046] (2) VS loaded with three-dimensional nanoflower structure 2 The graphene paper was annealed in an oxygen environment, the annealing temperature was 200°C, and the annealing time was 1 h to obtain a three-dimensional nanoflower structure vanadium pentoxide positive electrode material;

[0047] (3) Grind the vanadium pentoxide positive electrode material with a three-dimensional nanoflower structure into a powder particle with a particle size of 5-50 μm, mix it with NMP and Super P to obtain a mixed solution B, and add the mixed solution B dropwise to the 100 μm thick Garnet solid electrolyte...

Embodiment 2

[0050] (1) Set the size to 2 cm 2 , the graphene paper with a thickness of 50 μm was placed in the precursor mixed aqueous solution A with a mass ratio of 1:3 thioacetamide and ammonium metavanadate, and hydrothermally reacted at 180°C for 24 h to obtain a three-dimensional nanoflower structure vanadium disulfide VS 2 , wherein the concentration of mixed aqueous solution A is 50 g / L;

[0051] (2) VS loaded with three-dimensional nanoflower structure 2 The graphene paper was annealed in the air environment, the annealing temperature was 400 ° C, and the annealing time was 2 h to obtain a three-dimensional nanoflower structure vanadium pentoxide positive electrode material;

[0052] (3) Grind the vanadium pentoxide positive electrode material with a three-dimensional nanoflower structure into a powder particle with a particle size of 5-50 μm, mix it with NMP and Super P to obtain a mixed solution B, and add the mixed solution B dropwise to the 50 μm thick Garnet solid electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com