Shape memory wound closing device

A closed device and memory polymer technology, applied in the field of medical devices, can solve the pain of the injured and other problems, and achieve the effect of good continuity, simple steps and fast process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The manufacture and use of the device of this embodiment include the following steps:

[0026] Step 1, take polyurethane (PU) as raw material, dissolve it in chloroform-dimethylformamide (DMF) mixed solvent with a concentration ratio of 1:1, and prepare a polyurethane-chloroform-DMF solution with a polyurethane concentration of 20% .

[0027] Step 2, put the prepared polyurethane-chloroform-DMF solution into the electrospinning machine, and then spin the film with the parameters of spinning voltage 6kV, drum speed 700 rpm / min, and spinning distance 6 cm, and cut it into a length of 30 mm. Several long polyurethane strips with a width of 3 mm and a thickness of 0.5 mm (that is, fiber membrane 1).

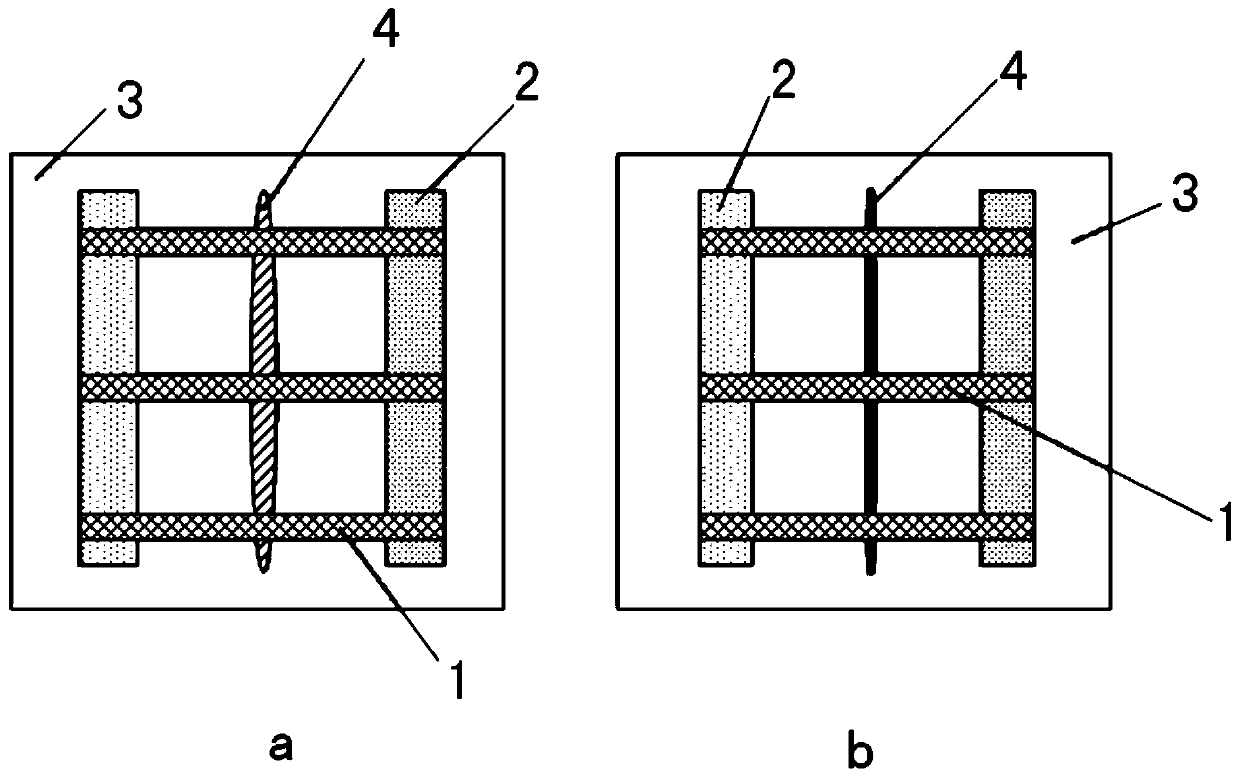

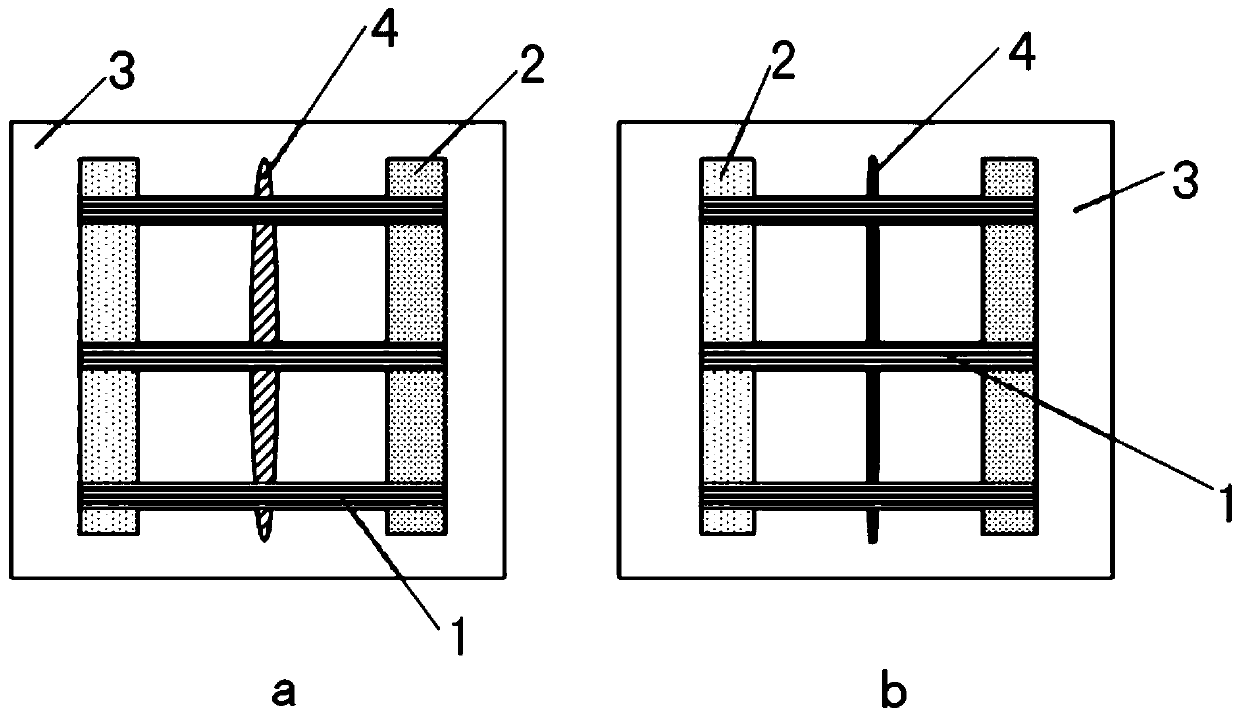

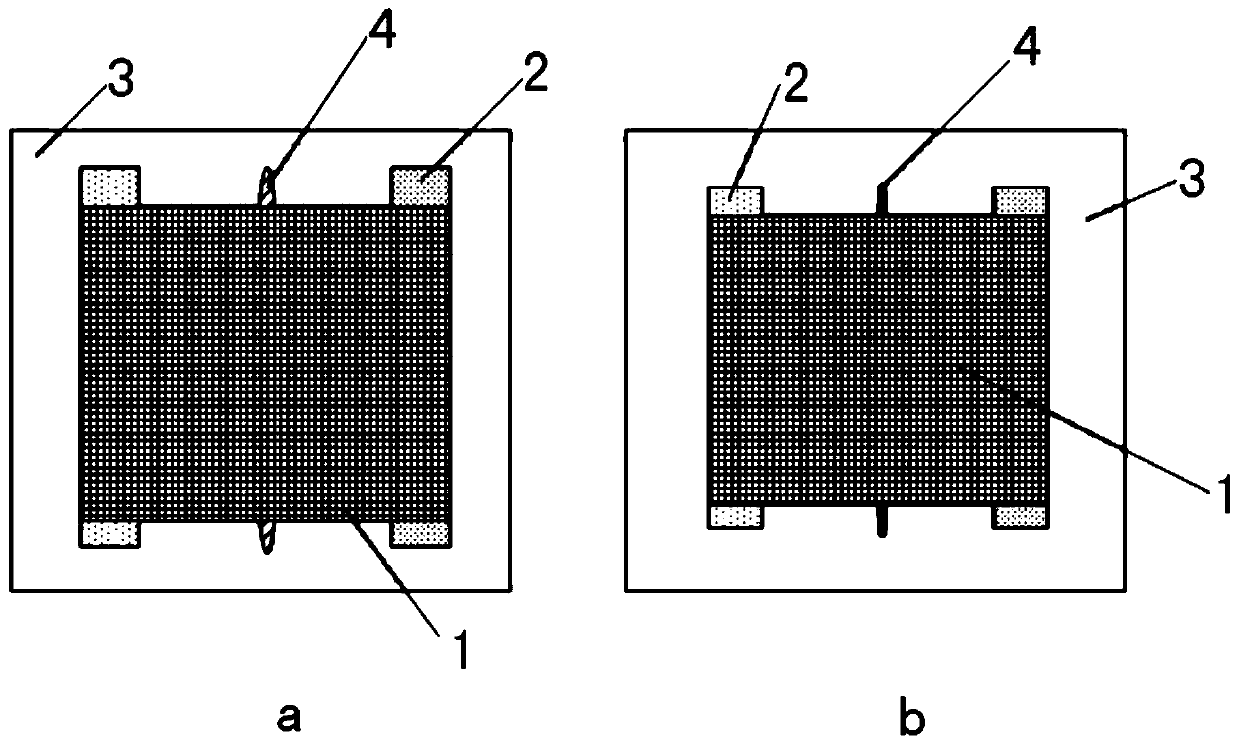

[0028] Step 3, paste several long polyurethane strips on the non-adhesive surface of the medical adhesive tape 2 through the adhesive material layer on one side. For the specific arrangement, refer to figure 1 , the shape memory wound closure device was fabricated.

[0029]...

Embodiment 2

[0032] The manufacture and use of the device of this embodiment include the following steps:

[0033] Step 1, using polyurethane (PU) as raw material, dissolve it in a mixed solution of acetone and dimethylformamide (V / V) at a concentration ratio of 1:1 (V / V), and prepare polyurethane-acetone-two Methylformamide solution.

[0034] Step 2, put the prepared polyurethane-acetone-dimethylformamide solution into the electrospinning machine, and then spin the film with the parameters of spinning voltage 6 kV, drum speed 500 rpm / min, and spinning distance 8 cm Afterwards, several long polyurethane strips with a length of 28 mm, a width of 2.2 mm and a thickness of 0.15 mm are cut.

[0035] Step 3, heat several long strips of polyurethane strips to 50°C and pre-stretch them by 30%, and then paste them on the non-adhesive surface of the medical adhesive tape. For the specific arrangement, refer to figure 1 , the shape memory wound closure device was fabricated.

[0036] Step 4, refe...

Embodiment 3

[0040] The manufacture and use of the device of this embodiment include the following steps:

[0041] Step 1, using polycaprolactone (PCL) as a raw material, dissolve it in dimethylformamide: chloroform 1:1 (V / V) mixed solvent, and prepare polycaprolactone with a polycaprolactone concentration of 18%. Lactone-dimethylformamide-chloroform solution.

[0042] Step 2, put the prepared polycaprolactone-dimethylformamide-chloroform solution into the electrospinning machine, and then use the parameters of spinning electricity 8 kV, drum speed 600 rpm / min, and spinning distance 10 cm After weaving out the film, cut a number of elongated polycaprolactone strips with a length of 28 mm, a width of 2.2 mm, and a thickness of 0.15 mm.

[0043] Step 3. Pre-stretch several long polycaprolactone strips by 30% at room temperature and paste them on the non-adhesive surface of the medical adhesive tape. For the specific arrangement, refer to figure 1 , the shape memory wound closure device was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com