White LED chip structure and manufacturing method thereof

An LED chip and manufacturing method technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of image color distortion, cumbersome process, phosphor aging, etc., to avoid energy loss, simple manufacturing process, and high luminous efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

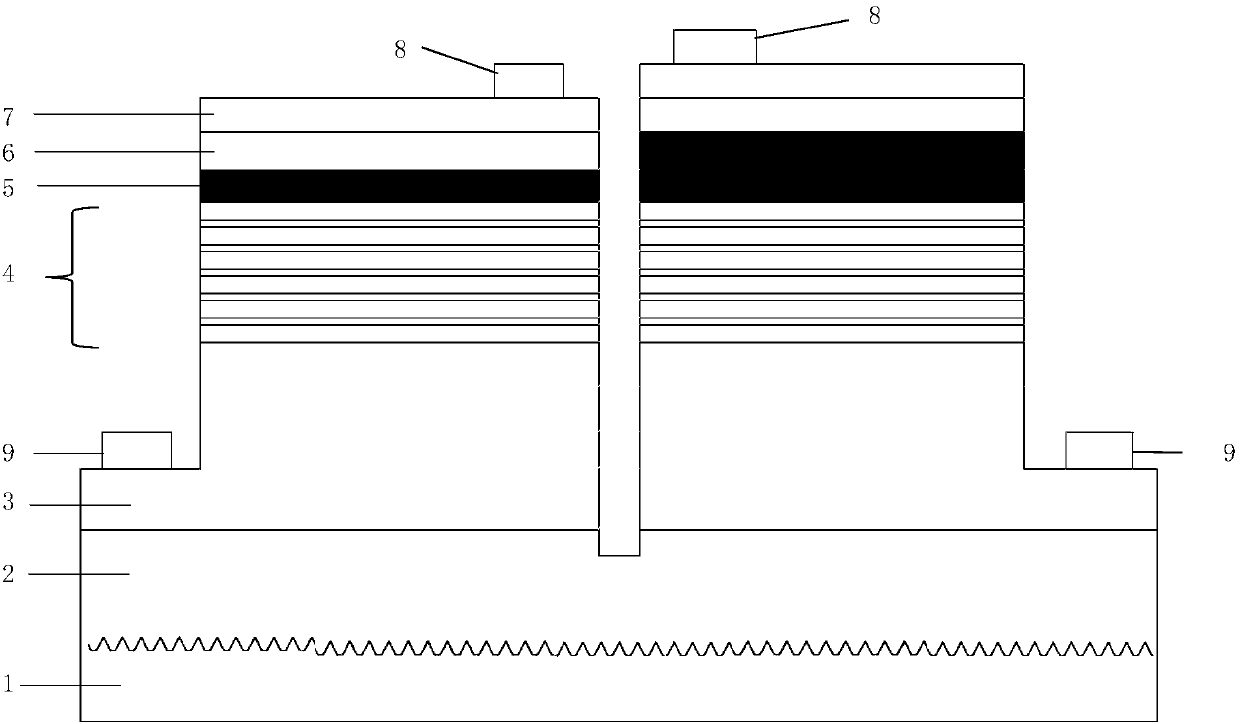

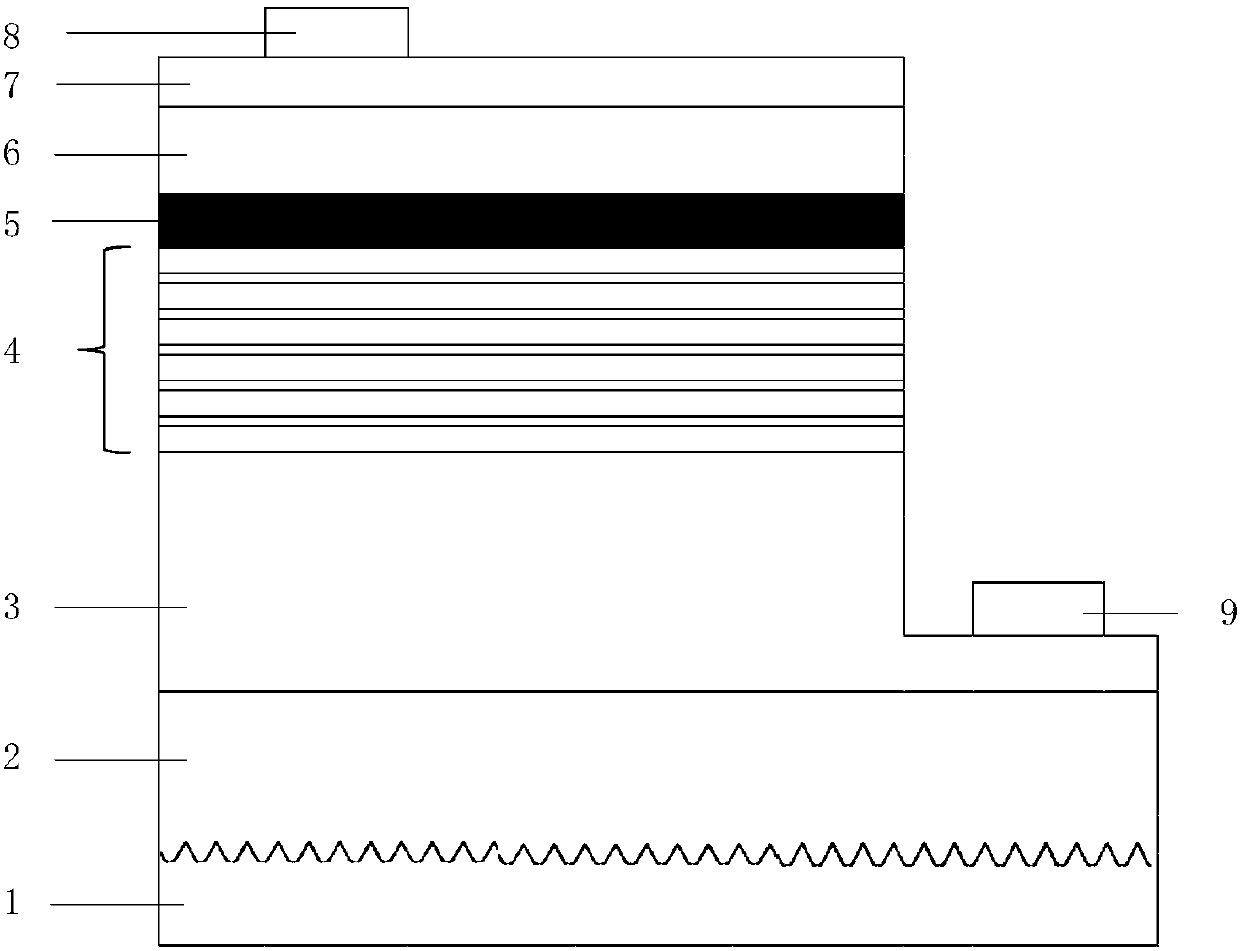

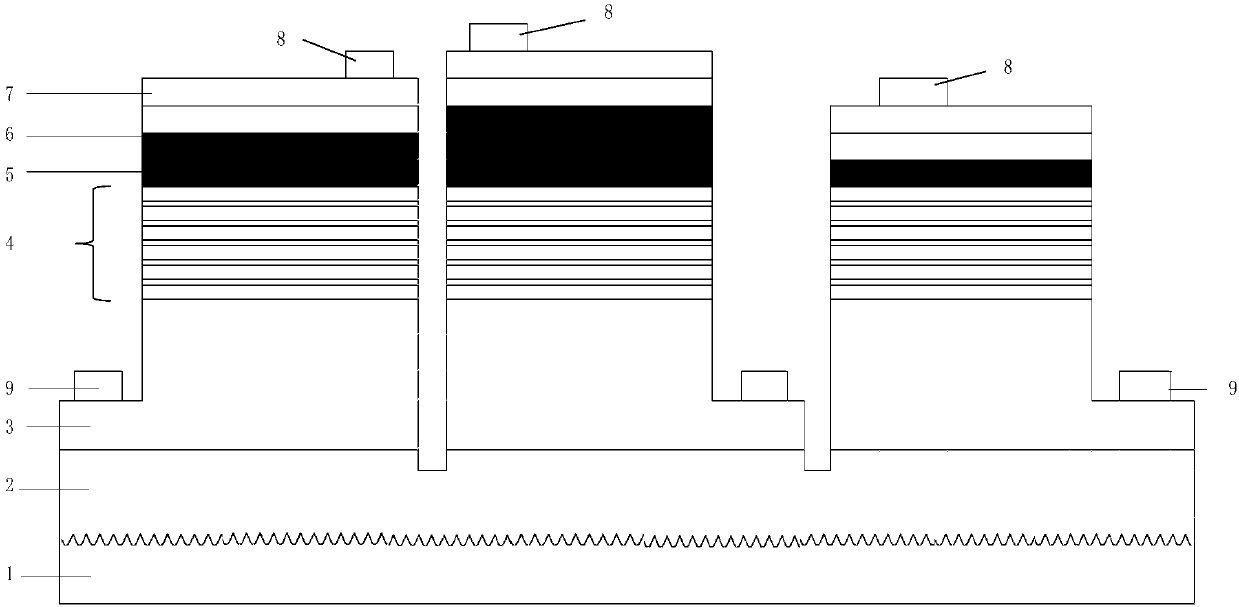

[0022] Such as figure 2 As shown, Embodiment 1 of the present invention provides a white light LED chip structure. At least two sub-chips are provided on the same LED chip. The sub-chips include a substrate 1 and an epitaxial layer formed on the substrate. The epitaxial layer is provided with The electron blocking layer 5 and the light-emitting layer 4, by setting the thickness of the electron blocking layer 5 of different sub-chips, cooperate with the light-emitting layer 4, different sub-chips can emit light of different wavelengths, and the lights of different wavelengths are mixed to form white light.

[0023] A white light LED chip structure provided by Em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com