Linear motor generator power supply

A linear motor, power supply technology, applied in electrical components, electromechanical devices, etc., can solve the problems of low power density and application value, consumption of petroleum energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

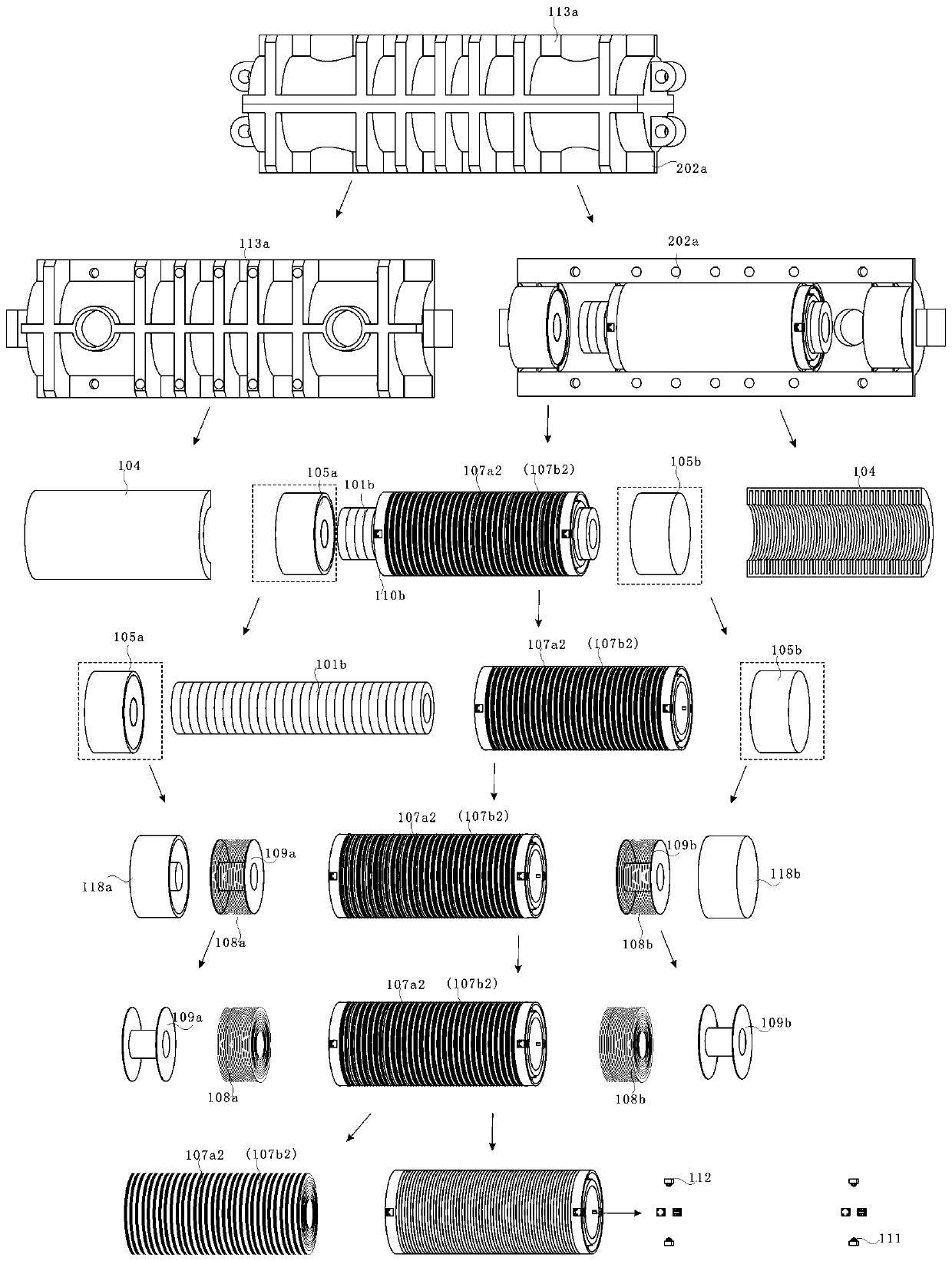

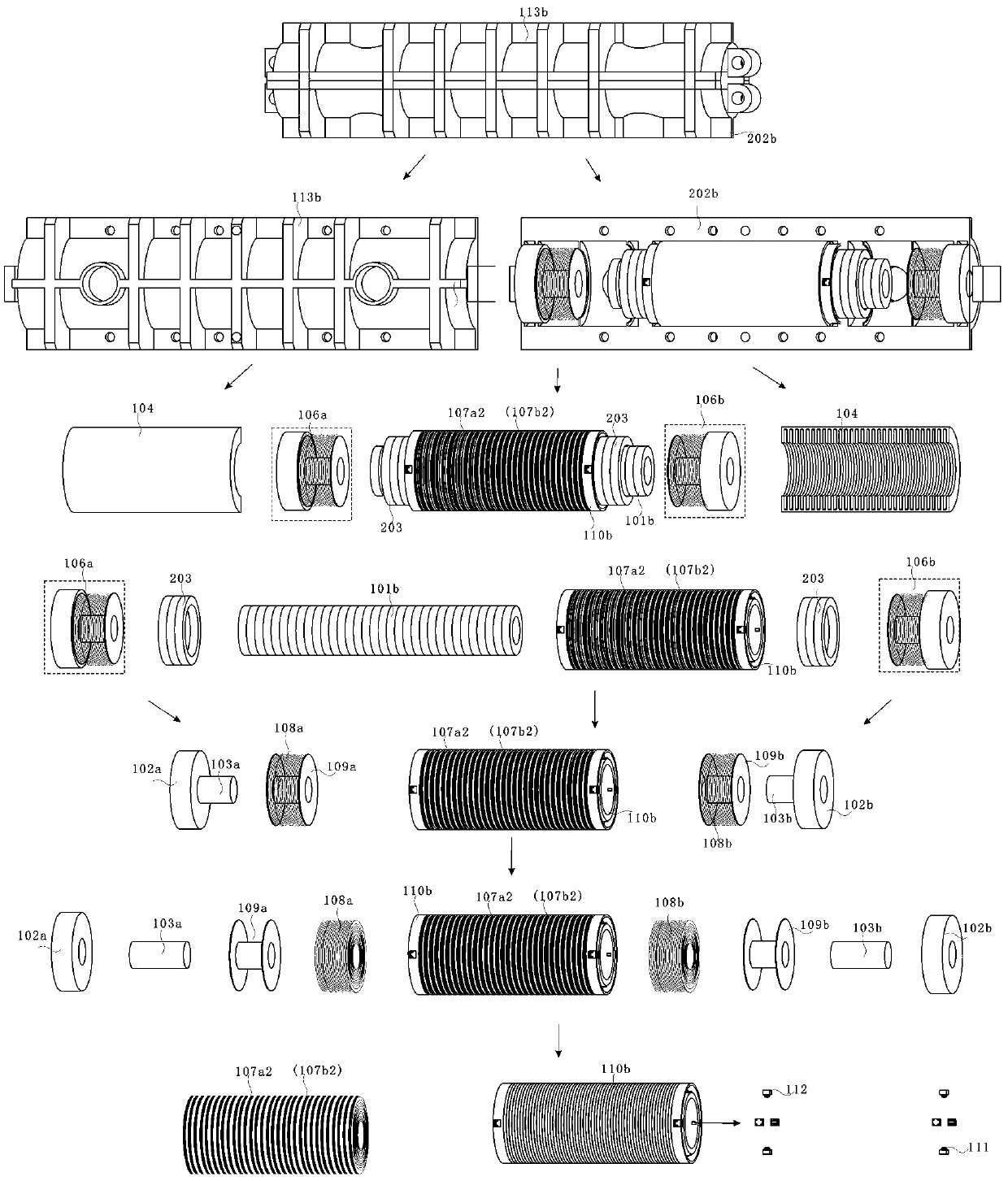

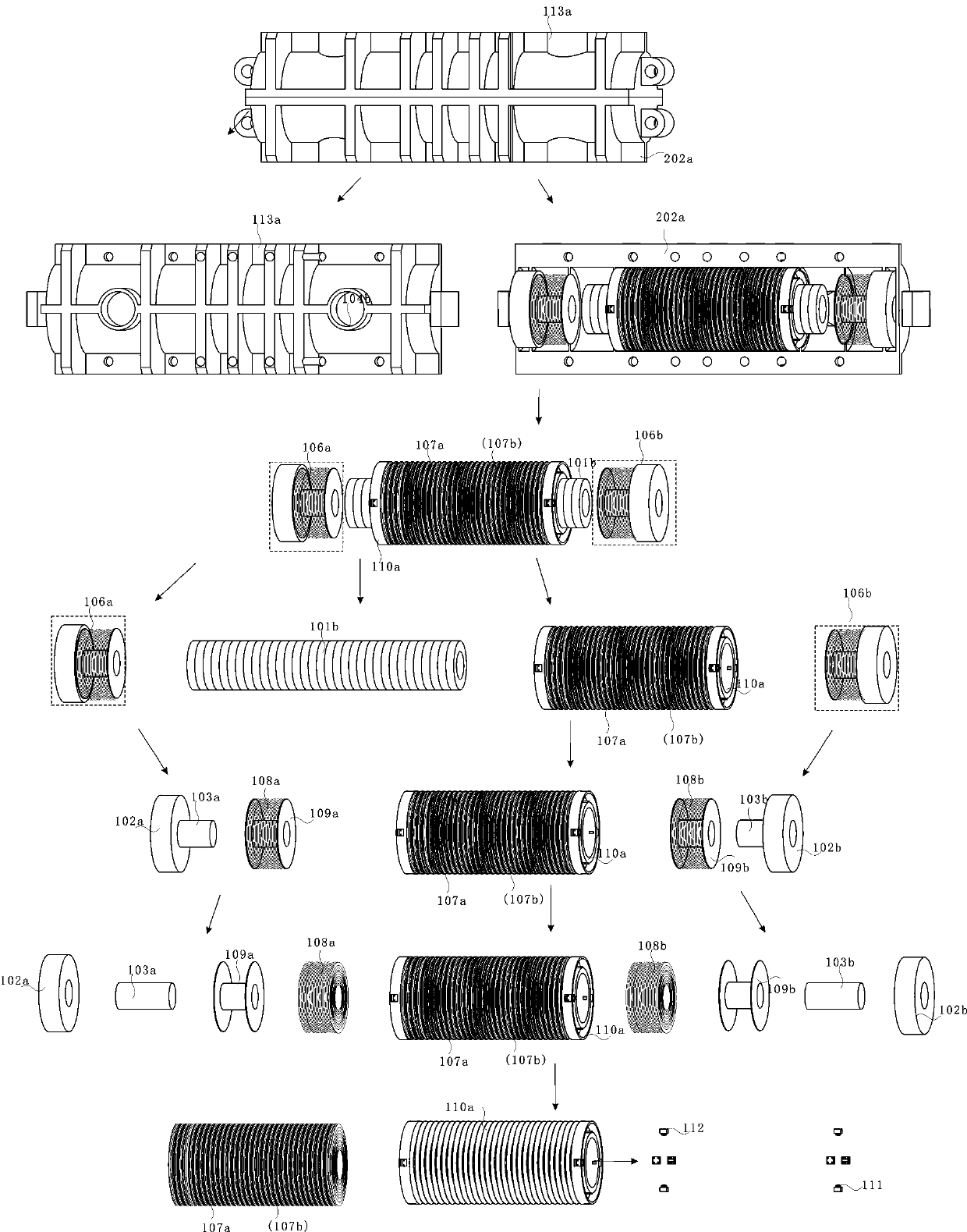

[0072] Specific embodiment one (see Figure 1-4 ) assembly assembly process steps are.

[0073] Step 1: 8 ceramic bearings are embedded in the inner wall of the two ends of the winding skeleton 110 cylinder, and 4 of each end form an angle of 90 degrees; Coaxial, the gland 112 is pressed on the ceramic bearing shaft, and the gland 112 is provided with a screw hole and fastened with the winding frame 110 to form a guide roller.

[0074] Step 2: The winding frame 110a has a plurality of annular grooves, and the non-stator windings 107a and b are sequentially embedded, and the outer peripheral surfaces of the non-stator windings 107a2 and b2 are resin-filled to form the non-stator windings 107a and b.

[0075] Step 3: Stator windings 107a2 and b2 are sequentially embedded in a plurality of circular grooves in the winding frame 110b, and the outer peripheral surfaces of the stator windings 107a2 and b2 are resin-filled to form no stator windings 107a2 and b2.

[0076] Step 4: Wi...

specific Embodiment 2

[0084] Specific embodiment two, ( Image 6 , 7 and 8) Linear motor generator drive mode 1, dual control bidirectional Buck-BoostDC / DC converters VT20, VT21, VT10, VT11 are turned on and VT19, VT22, VT9, VT12 are turned off, and the super capacitor module has 304 DC directions Bus discharge, supercapacitor module 305 charging, single-phase inverter circuit VT2, VT3, VT5, VT8 off, pulse-type alternate conduction on VT1, VT4 and VT6, VT7, excitation coil 108a or b is energized and driven, forcing the permanent magnet The array free piston mover 101 reciprocates axially, the bidirectional thyristors U1, U2 and U3, U4 alternately control the rectification and isolation circuits 302a and 302b, the excitation coil 108a or 108b and the stator winding 107a or 107a2 generate an induced current, which is output through rectification and filtering. The two-way Buck-Boost DC / DC converter is controlled by joint connection busbars to charge the supercapacitor module 305; when the voltage of ...

specific Embodiment 3

[0085] Specific embodiment three, ( Image 6 , 7 And 8) Linear motor generator drive mode 2, dual control bidirectional Buck-BoostDC / DC converter VT20, VT21, VT10, VT11 on and VT19, VT22, VT9, VT12 off, super capacitor module 304 directions Bus discharge, supercapacitor module 305 charging, three-phase inverter circuit VT13-VT18 IGBT tube phase sequence two-two pulse conduction stator winding 107b and single-phase inverter circuit VT1-VT8 off, forcing the permanent magnet array free piston The mover 101 is suspended and reciprocated in the axial direction, the bidirectional thyristors control the rectification circuits U1, U2 and U3, U4 and U5, U6 and U7, U8 and U9, and U10 alternately control the rectification and isolation circuits 302a or 302b and 309, 310 or 311, and the excitation coil 108a or 108b, the stator winding 107a or 107a2, and one phase of the stator winding 107b or b2 generate an induced current, output it through rectification and filtering, and jointly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com