Novel powder metallurgy production process of high-performance automobile synchronizer gear ring

A synchronizer gear ring and powder metallurgy technology, which is applied in the field of new powder metallurgy production technology of high-performance automobile synchronizer gear ring, can solve the problems of high manufacturing cost, low material utilization rate, complex machining process, etc., and achieve low cost , low scrap rate, and the effect of improving product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

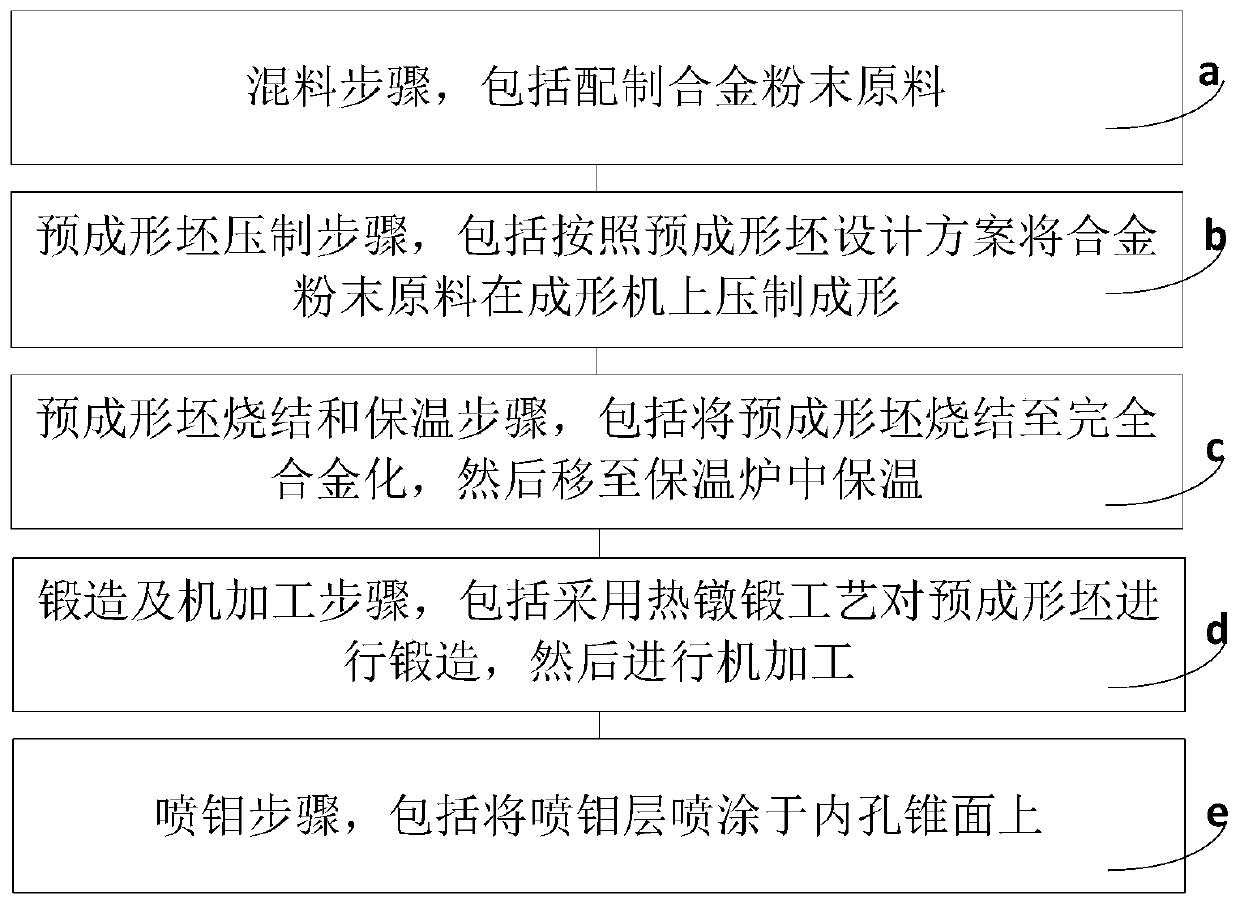

[0044] 1. Select the domestic water atomized AISI4600 low-alloy steel powder with good cost performance and good pressing, sintering and forging process performance as the alloy powder raw material, and mix it evenly.

[0045] 2. Using the simple shape preform design scheme, the alloy powder is pressed and formed on the forming machine, and the forming density is 6g / cm 3 , The quality deviation is controlled at ±0.5%.

[0046] 3. Sinter the preform at 1100°C in a non-oxidizing environment until it is completely alloyed, and then move the sintered body into a holding furnace at 1000°C in a non-oxidizing atmosphere for heat preservation.

[0047] 4. Quickly move the preform to the forging die which has been preheated at 250°C. The exposure time in the air is controlled within 5 seconds. The forging temperature is 910°C. After the forging is released from the mold, it is slowly cooled in a sandbox. It is then machined using a CNC machine.

[0048] 5. Spray the molybdenum spray ...

Embodiment 2

[0050] 1. Select the domestic water atomized AISI4600 low-alloy steel powder with good cost performance and good pressing, sintering and forging process performance as the alloy powder raw material, and mix it evenly.

[0051] 2. Using the simple shape preform design scheme, the alloy powder is pressed and formed on the forming machine, and the forming density is 7g / cm 3 , The quality deviation is controlled at ±0.5%.

[0052] 3. The preform is sintered at 1130°C in a non-oxidizing environment until it is completely alloyed, and then the sintered body is moved into a holding furnace at 1000°C in a non-oxidizing atmosphere for heat preservation.

[0053] 4. Quickly move the preform to the preheated forging die at 260°C. The exposure time in the air is controlled within 5 seconds. The forging temperature is 950°C. After the forging is released from the mold, it is slowly cooled in a sandbox. It is then machined using a CNC machine.

[0054] 5. Spray the molybdenum spray layer ...

Embodiment 3

[0056] 1. Select the domestic water atomized AISI4600 low-alloy steel powder with good cost performance and good pressing, sintering and forging process performance as the alloy powder raw material, and mix it evenly.

[0057] 2. Using the simple shape preform design scheme, the alloy powder is pressed and formed on the forming machine, and the forming density is 6.5g / cm 3 , The quality deviation is controlled at ±0.5%.

[0058] 3. The preform is sintered at 1120°C in a non-oxidizing environment until it is completely alloyed, and then the sintered body is moved into a holding furnace at 1000°C in a non-oxidizing atmosphere for heat preservation.

[0059] 4. Quickly move the preform to the forging die that has been preheated at 300°C. The exposure time in the air is controlled within 5 seconds. The forging temperature is 900°C. After the forging is released from the mold, it is slowly cooled in a sand box. It is then machined using a CNC machine.

[0060] 5. Spray the molybd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com