Soluble hydrogel microsphere and preparation method and application thereof in single cell detection

A hydrogel microsphere, soluble technology, applied in biochemical equipment and methods, immobilized on/in organic carriers, determination/inspection of microorganisms, etc., can solve the problem of reducing single cell capture rate, channel blockage, plastic It can solve the problems of poor plasticity of beads, and achieve the effect of solving difficult operation, preventing channel blockage and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] One aspect of the embodiments of the present invention provides a method for preparing soluble hydrogel microspheres, comprising:

[0035] mixing acrylamide, N,N-bis(acryloyl)amide, acetic acid and 2-hydroxy-2-methyl-1-phenyl-1-propanone uniformly to form a mixed mother liquor;

[0036] Mix the mixed mother liquor and sodium hydroxide evenly to obtain a prepolymer solution;

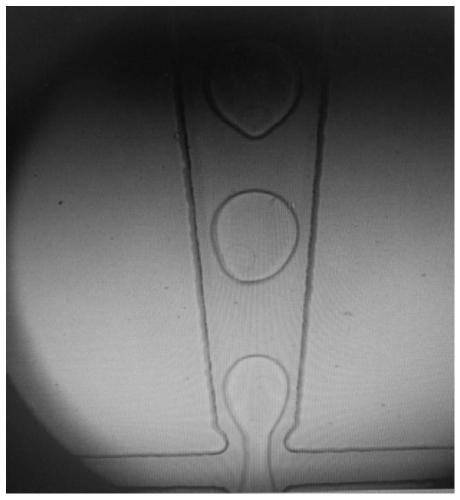

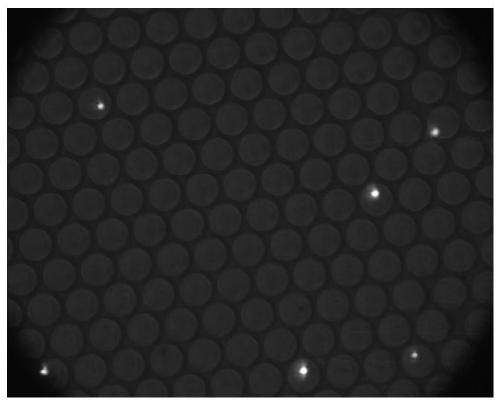

[0037] Using a single emulsion device, the prepolymer solution is used as the inner phase and the oil phase substance is used as the outer phase to prepare microdroplets, and then online polymerization at 30° C. to 65° C. for 10 to 14 hours to obtain soluble hydrogel microspheres.

[0038] In some embodiments, the flow rate of the prepolymer solution is 200-400 μL / h, the flow rate of the oil phase substance is 400-600 μL / h, and an appropriate flow rate is selected according to the required microsphere size.

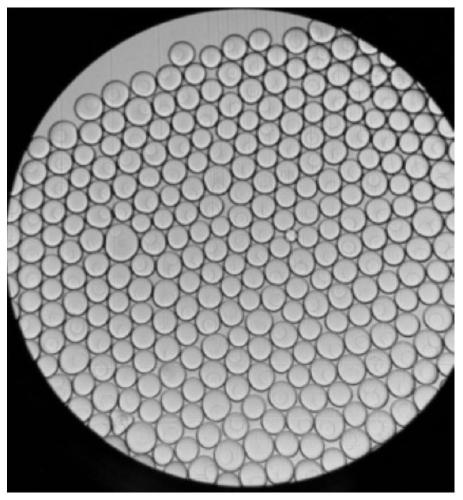

[0039] Further, the diameter of the soluble hydrogel microsphere is 20-120 μm. By adjust...

Embodiment 1

[0076] (1) Prepare the microfluidic chip

[0077] (2) Preparation of soluble hydrogel microspheres:

[0078] 1) Weigh 0.29g of acrylamide, 0.01g of N,N-bis(acryloyl)amide, dissolve in 1ml of 10% acetic acid, and add 3μL of 2-hydroxy-2-methyl-1-phenyl- 1-Acetone to give a total volume of 1 mL of 30% mother liquor.

[0079] 2) Mix 300 μL of the mother liquor with 600 μL of 1 mol / L sodium hydroxide to obtain a prepolymer solution with a concentration of 10%.

[0080] 3) Using the above-mentioned prepolymer solution as the internal phase, silicone oil as the external phase, the flow rate of the prepolymer solution is 250 μL / h, and the flow rate of the oil phase substance is 450 μL / h, and micro-droplets are prepared by a single emulsion device.

[0081] 4) Polymerization at 65°C for 12 hours.

[0082] 5) Wash with n-hexane several times to remove excess silicone oil. Then use ethanol aqueous solution (100%, 90%,

[0083] 80%, 75%, 50%) gradient replacement, and finally collect...

Embodiment 2

[0091] (1) Prepare the microfluidic chip

[0092] (2) Preparation of soluble hydrogel microspheres:

[0093] 1) Weigh 0.22g of acrylamide, 0.01g of N,N-bis(acryloyl)amide, dissolve in 1ml of 10% acetic acid, and add 3μL of 2-hydroxy-2-methyl-1-phenyl- 1-Acetone to give a total volume of 1 mL of 30% mother liquor.

[0094] 2) Mix 300 μL of the mother liquor with 600 μL of 1 mol / L sodium hydroxide to obtain a prepolymer solution with a concentration of 10%.

[0095] 3) The above-mentioned prepolymer solution is used as the internal phase, the silicone oil is used as the external phase, the flow rate of the prepolymer solution is 300 μL / h, and the flow rate of the oil phase substance is 500 μL / h, and micro-droplets are prepared by a single emulsion device.

[0096] 4) Polymerization at 60°C for 12 hours.

[0097] 5) Wash with n-hexane several times to remove excess silicone oil. Afterwards, gradient replacement with ethanol aqueous solution (100%, 90%, 80%, 75%, 50%) was carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com