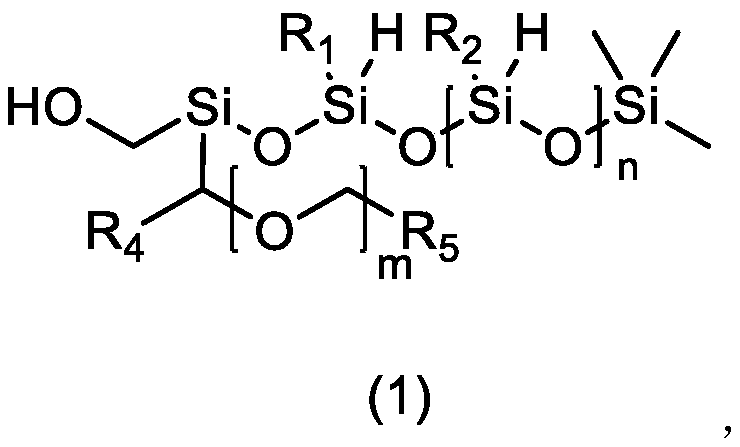

Hydroxyl polyether modified siloxane and preparation method thereof

A hydroxy polyether and siloxane technology, used in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve problems such as difficult cleaning, strong adhesion of stains on the surface of the coating, and needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

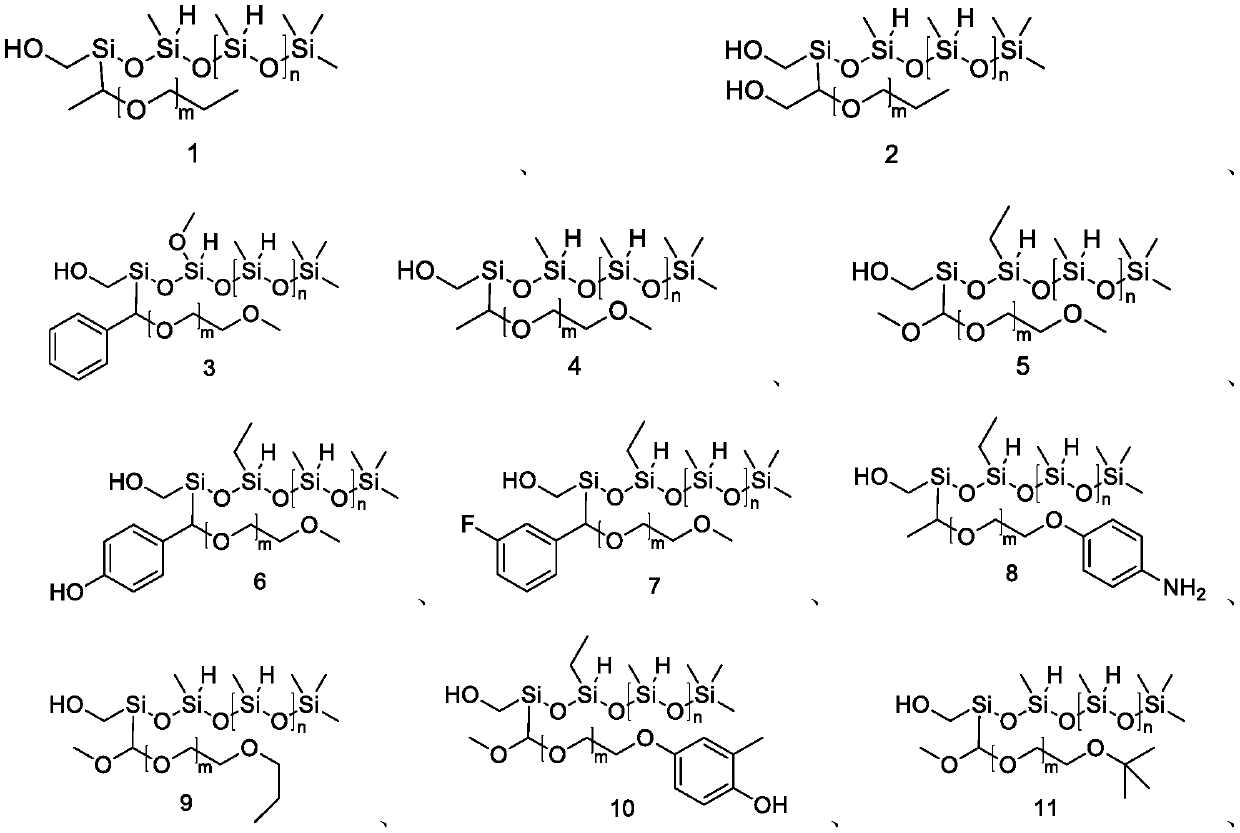

Method used

Image

Examples

Embodiment 1

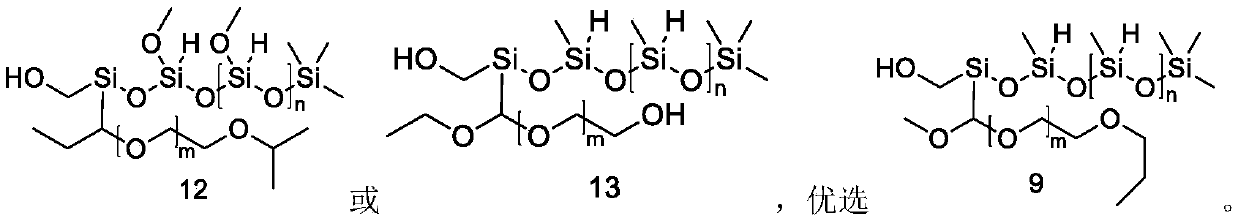

[0055] Embodiment 1, the preparation of polymer 9

[0056]

[0057] The synthetic route is as follows:

[0058]

[0059] Reagents: Compound a-9 was purchased from Shenyao (Xianghe) Technology Co., Ltd.; Compound b-9 was prepared according to the method reported by Kuryla W C ([J].The Journal of Organic Chemistry,1965,30(11):3926-3929) ; Chloroplatinic acid was purchased from Shanghai Yansheng Co., Ltd.

[0060] Specific preparation method:

[0061] In the 1000mL four-necked flask with stirrer and thermometer, first add 400g of compound b-9 and 4mLspeier catalyst (1g chloroplatinic acid is dissolved in 120mL anhydrous isopropanol and fully stirred to obtain), N 2 Start stirring under protection, slowly increase the temperature to 90°C, activate at this temperature for 1.5 hours, then continuously drop 200g of compound a-9 into the system, control the reaction temperature between 100-110°C, and react after the dropwise addition 3-4 hours, continuous sampling for infrare...

Embodiment 2

[0065] Embodiment 2, the preparation of the cleanable wear-resistant topcoat containing compound 9

[0066] Reagents: UV resin and acrylate were purchased from Taiwan Changxing Resin, defoamer BYK141, dispersant BYK164, anti-sedimentation agent BYK204, and initiator BP-184 were purchased from Shanghai Buding Chemical Co., Ltd. Fully mix and disperse 600g of 100% UV resin, 50g of acrylate, 5g of defoamer BYK141, 8g of dispersant BYK164, and 20g of initiator BP-184; then add anti-scratch filler powder, anti-sedimentation powder, and matting powder 1 In the prepared mixture, continue to disperse evenly; add 25g of polymer 9 and 5g of anti-settling agent BYK204 into the mixture prepared in step 2, continue to disperse fully, and prepare a cleanable and wear-resistant topcoat.

Embodiment 3

[0067] Embodiment 3, abrasion resistance test

[0068] Comparative sample: The comparative sample was prepared according to the method described in Example 2 of patent CN102002316A.

[0069] Test sample: prepared according to the method described in Example 2.

[0070] Test method: According to the method of ASTM1044, put the grinding wheel CS-10F into the Tabor wear test device, rotate the sample to be evaluated for 500 revolutions under the applied load of 500g, compare the haze of the sample before and after the test, and calculate the haze change ( ΔH), the wear resistance was evaluated based on the following criteria: ΔH≤5.0, good wear resistance; 5.0<ΔH<10.0, poor wear resistance; 10.0≤ΔH, extremely poor wear resistance.

[0071] Test results: ΔH≤5.0 of the sample of the test example, good wear resistance; while 5.0<ΔH<10.0 of the sample of the comparative example, poor wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com