A flame-retardant and aging-resistant plastic shell

A plastic shell, aging-resistant technology, applied in the field of plastic shells, can solve the problems of poor impact resistance of PVC, lack of flame retardancy and aging resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

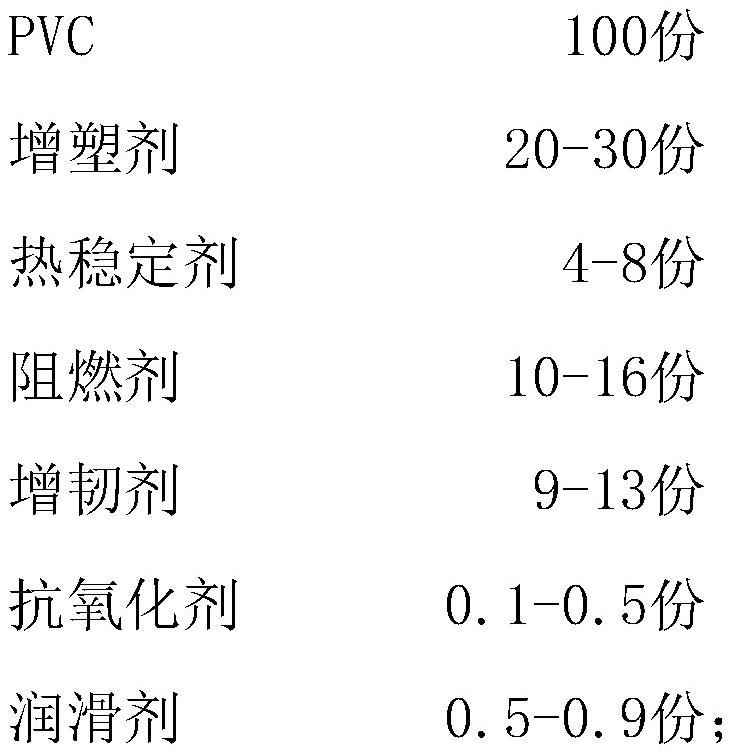

[0027] A flame-retardant and aging-resistant plastic shell, comprising the following raw materials in parts by weight:

[0028]

[0029] Wherein, the preparation method of described toughening agent comprises the steps:

[0030] (1) alcoholysis: get castor oil and glycerin and carry out alcoholysis reaction under the catalysis of catalyzer, temperature of reaction is 210 ℃, and the reaction time is 2h, obtains alcoholysis castor oil, and the weight ratio of described castor oil, glycerin and catalyzer is 500:100:2 ratio composition;

[0031] (2) Modification: Take 2,4-diisocyanate toluene and dissolve it in N,N-dimethylacetamide, add nano silicon dioxide and stir and mix to obtain an isocyanate solution, the 2,4-diisocyanate The weight ratio of cresyl isocyanate, nano silicon dioxide and N,N-dimethylacetamide is 6:1.5:10;

[0032] (3) Polyurethane synthesis: the alcoholyzed castor oil is added to the isocyanate solution to react, the reaction temperature is 60°C, and the ...

Embodiment 2

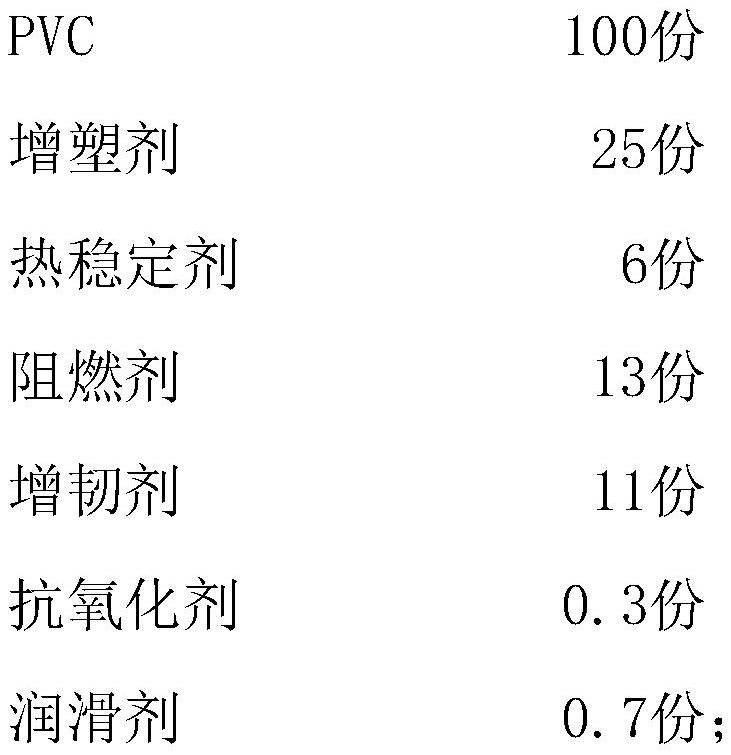

[0043] A flame-retardant and aging-resistant plastic shell, comprising the following raw materials in parts by weight:

[0044]

[0045] Wherein, the preparation method of described toughening agent comprises the steps:

[0046] (1) alcoholysis: get castor oil and glycerol to carry out alcoholysis reaction under the catalysis of catalyzer, reaction temperature is 200 ℃, and reaction time is 1.5h, obtains alcoholylated castor oil, the weight ratio of described castor oil, glycerol and catalyzer Composed of a ratio of 500:80:1;

[0047] (2) Modification: Take 2,4-diisocyanate toluene and dissolve it in N,N-dimethylacetamide, add nano silicon dioxide and stir and mix to obtain an isocyanate solution, the 2,4-diisocyanate The weight ratio of cresyl isocyanate, nano silicon dioxide and N,N-dimethylacetamide is 5:1:10;

[0048] (3) Polyurethane synthesis: the alcoholyzed castor oil is added to the isocyanate solution to react, the reaction temperature is 50°C, and the reaction ...

Embodiment 3

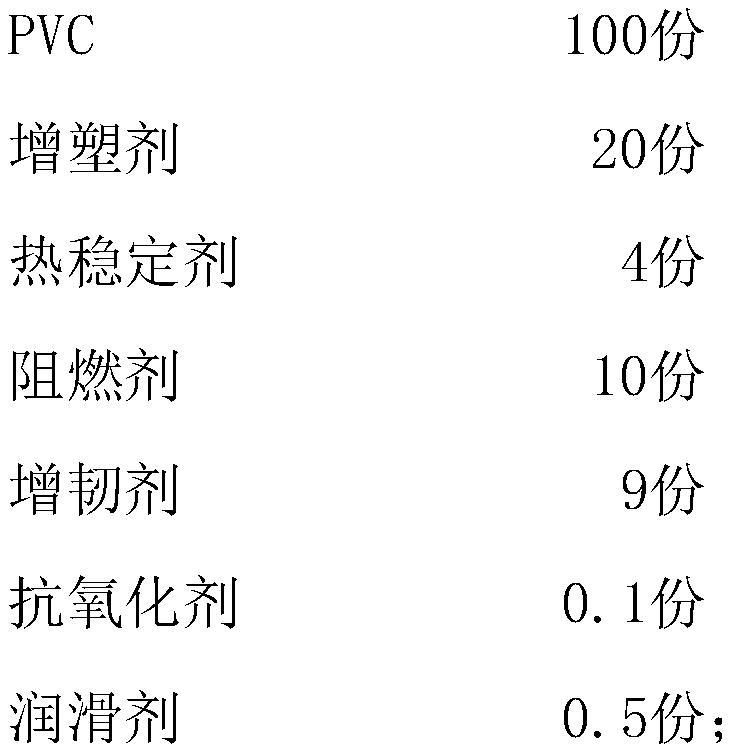

[0059] A flame-retardant and aging-resistant plastic shell, comprising the following raw materials in parts by weight:

[0060]

[0061]

[0062] Wherein, the preparation method of described toughening agent comprises the steps:

[0063] (1) alcoholysis: get castor oil and glycerin to carry out alcoholysis reaction under the catalysis of catalyzer, reaction temperature is 220 ℃, and reaction time is 2.5h, obtains alcoholylated castor oil, the weight ratio of described castor oil, glycerol and catalyzer Composed of a ratio of 500:120:3;

[0064] (2) Modification: Take 2,4-diisocyanate toluene and dissolve it in N,N-dimethylacetamide, add nano silicon dioxide and stir and mix to obtain an isocyanate solution, the 2,4-diisocyanate The weight ratio of cresyl isocyanate, nano silicon dioxide and N,N-dimethylacetamide is 7:2:10;

[0065] (3) Polyurethane synthesis: the alcoholyzed castor oil is added to the isocyanate solution to react, the reaction temperature is 70°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com