A kind of water-based metallic glitter paint

A technology of metal glitter paint and glitter paint, which is applied in the direction of metal-free paint, coating, polyurea/polyurethane coating, etc., and can solve the problems of poor product storage stability and a large amount of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

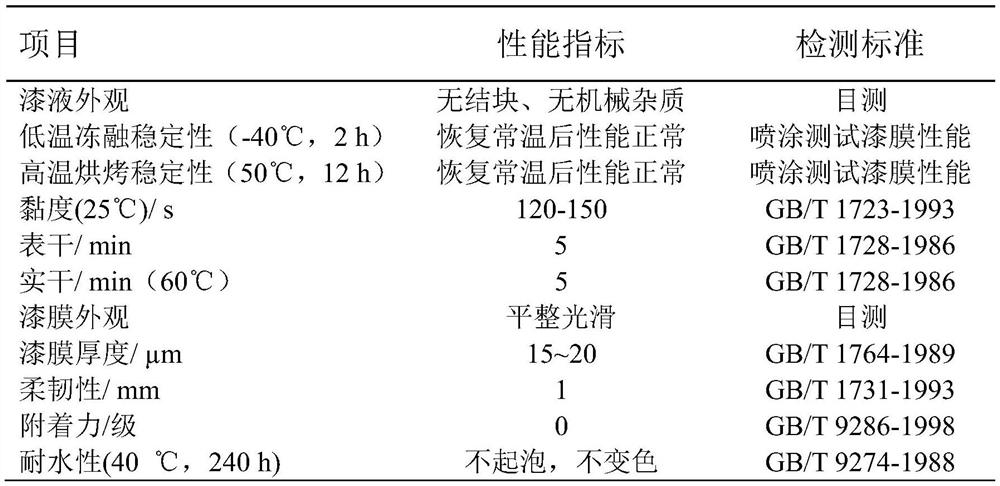

Examples

Embodiment 1

[0013] 1 Preparation of water-based metallic glitter paint

[0014] (1) Preparation of water-based polyurethane base material, including the following raw materials in parts by weight: 60 parts by weight of water-based polyurethane resin, 0.1 of siloxane defoamer, 0.15 of silicone surfactant wetting agent, 3 of water-based polyamide sodium salt emulsion anti-settling agent , deionized water 36.75. The preparation method is as follows: add water-based polyurethane resin into the container, add dimethylethanolamine neutralizer in the dispersed state to adjust the pH value to 7-7.5, and disperse for 5-10 minutes; add silicone defoamer, silicone surface active Wetting agent, water-based polyamide sodium salt emulsion anti-sedimentation agent, deionized water, etc., stirred for 20-30 minutes, and filtered with a 300-mesh filter cloth.

[0015] (2) Prepare water-based metallic glitter paint, comprising the following raw materials in parts by weight: aluminum silver paste 3, polyol ...

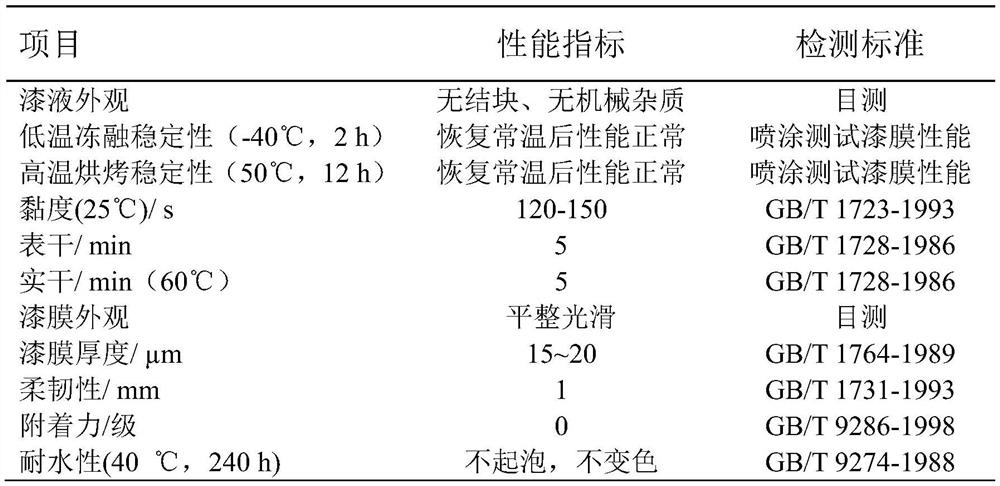

Embodiment 2

[0023] 1 Preparation of water-based metallic glitter paint

[0024] (1) Preparation of water-based polyurethane base material, comprising the following raw materials in parts by weight: 60 parts by weight of water-based polyurethane resin, 0.1 of silicone defoamer, 0.15 of organic silicon surfactant wetting agent, 3 of water-based polyamide sodium salt anti-settling agent, Deionized water 36.75. The preparation method is as follows: add water-based polyurethane resin into the container, add triethylamine neutralizer in the dispersed state to adjust the pH value to 7-7.5, and disperse for 5-10 minutes; add silicone defoamer and organic silicon surfactant in sequence Wetting agent, anti-sedimentation agent of water-based polyamide sodium salt emulsion, deionized water, etc., stirred for 20-30 minutes, and filtered with 300-mesh filter cloth.

[0025] (2) Prepare water-based metallic glitter paint, comprising the following raw materials in parts by weight: aluminum silver paste ...

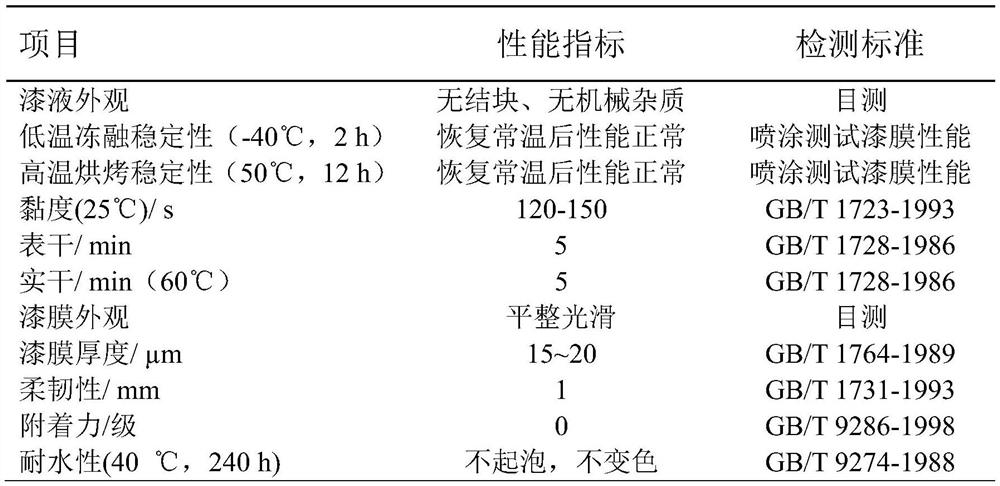

Embodiment 3

[0033] 1 Preparation of water-based metallic glitter paint

[0034] (1) Preparation of water-based polyurethane base material, comprising the following raw materials in parts by weight: water-based polyurethane resin 60, siloxane defoamer 0.1, organic silicon surfactant wetting agent 0.15, water-based polyamide sodium salt emulsion anti-settling agent 3. Deionized water 36.75. The preparation method is as follows: add the water-based polyurethane resin into the container, add the neutralizing agent of ammonia water in the dispersed state to adjust the pH value to 7-7.5, and disperse for 5-10 minutes; Wet agent, anti-sedimentation agent of water-based polyamide sodium salt emulsion, deionized water, etc., stir for 20-30 minutes, and filter with 300-mesh filter cloth.

[0035] (2) Prepare water-based metallic glitter paint, comprising the following raw materials in parts by weight: aluminum silver paste 3, film-forming cosolvent 20 of ethylene glycol tert-butyl ether, high mole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com