Hydrogen production system and method by coupling coal combustion with garbage water vapor gasification

A hydrogen production system and water vapor technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve the problems of low utilization rate of power plant equipment and the inability of steam turbines to operate at full capacity, and increase gas production. The efficiency and quality of gas production, the improvement of renewable energy, and the effect of ensuring continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

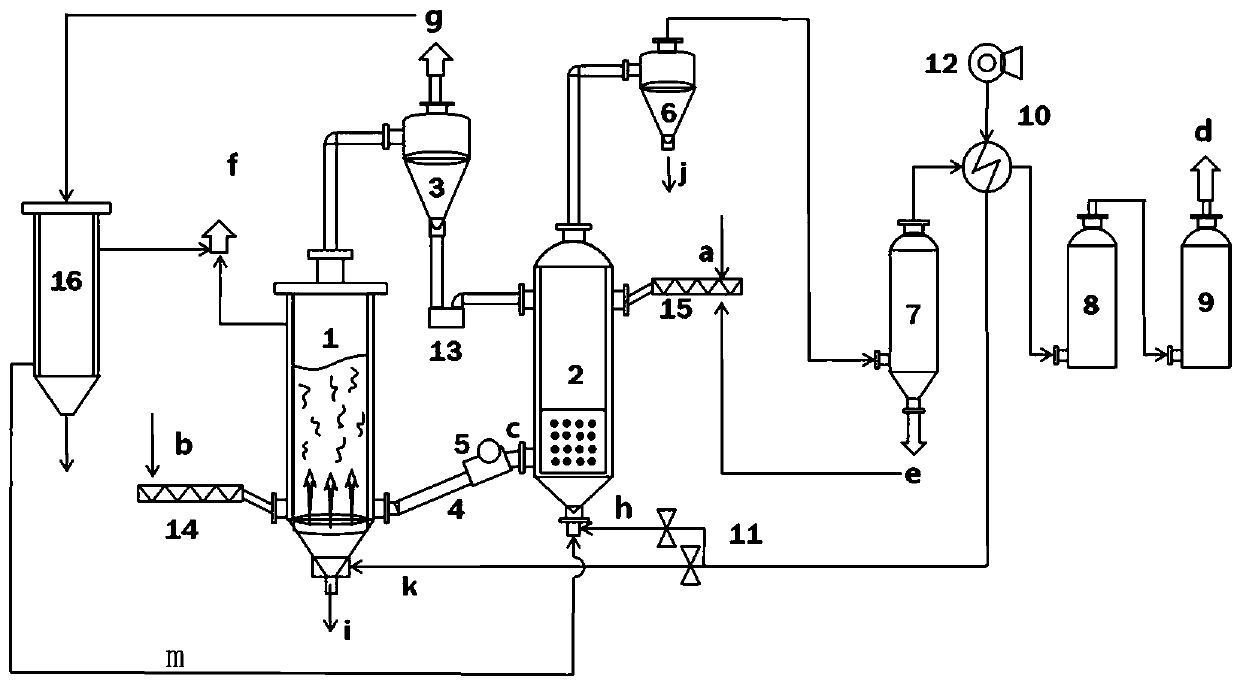

[0036] See attached picture. The hydrogen production system disclosed in this embodiment is a coal combustion coupled with steam gasification of garbage, including a circulating fluidized bed coal combustion system, a fixed bed garbage gasification system, and a synthesis gas treatment system. Among them, the design of the coal-fired system is based on the HG-480 / 13.7L.MG31 circulating fluidized bed boiler with a power of 135MW, and the design of the gasification system is based on the experimental data of the fixed bed.

[0037] The circulating fluidized bed coal combustion system includes: a fluidized bed combustion furnace 1 , a cyclone separator 3 at the outlet of the combustion furnace, a return leg 4 , a screw feeder 14 for the combustion furnace and a waste heat boiler 16 . The lower part of the left wall of the fluidized bed combustion furnace 1 is provided with a pulverized coal feeding port, which is connected with the screw feeder 14 of the combustion furnace, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com