Anti-biological-attachment rope

A bio-adhesion and anti-adhesion technology, applied in the direction of textile cables, textiles and paper, can solve the problems of reducing the service life of ropes, affecting the safety of marine operations, and the burden of ropes, so as to improve the use efficiency, simplify the structure and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

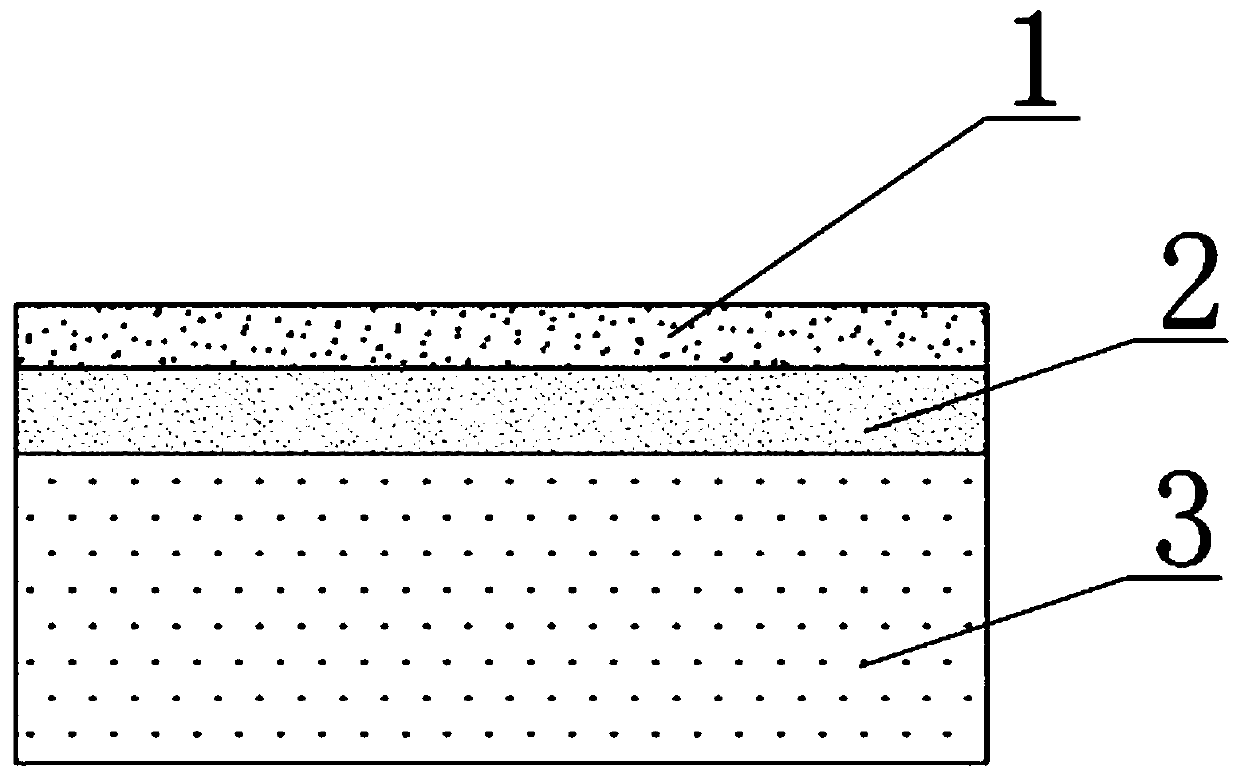

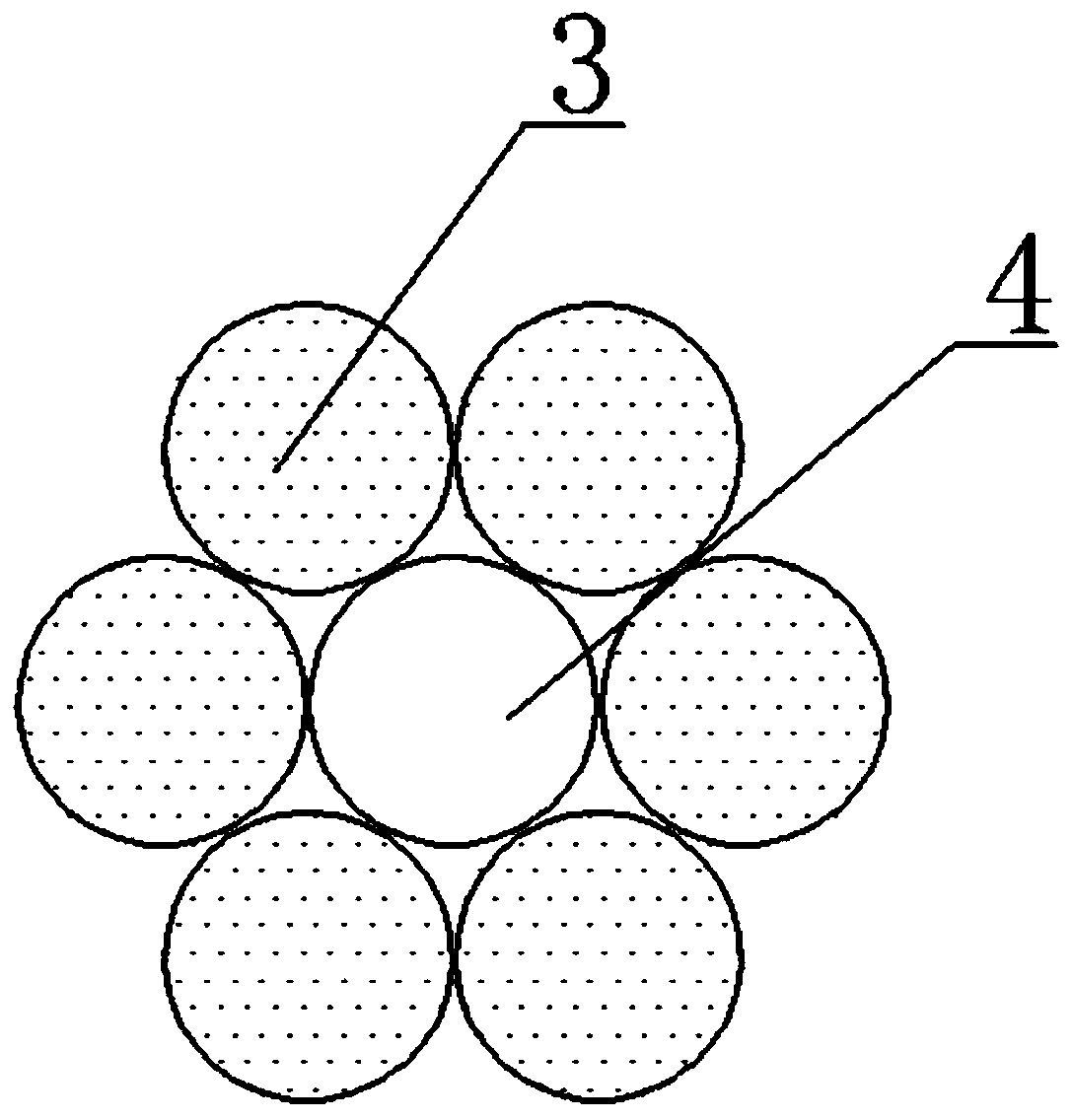

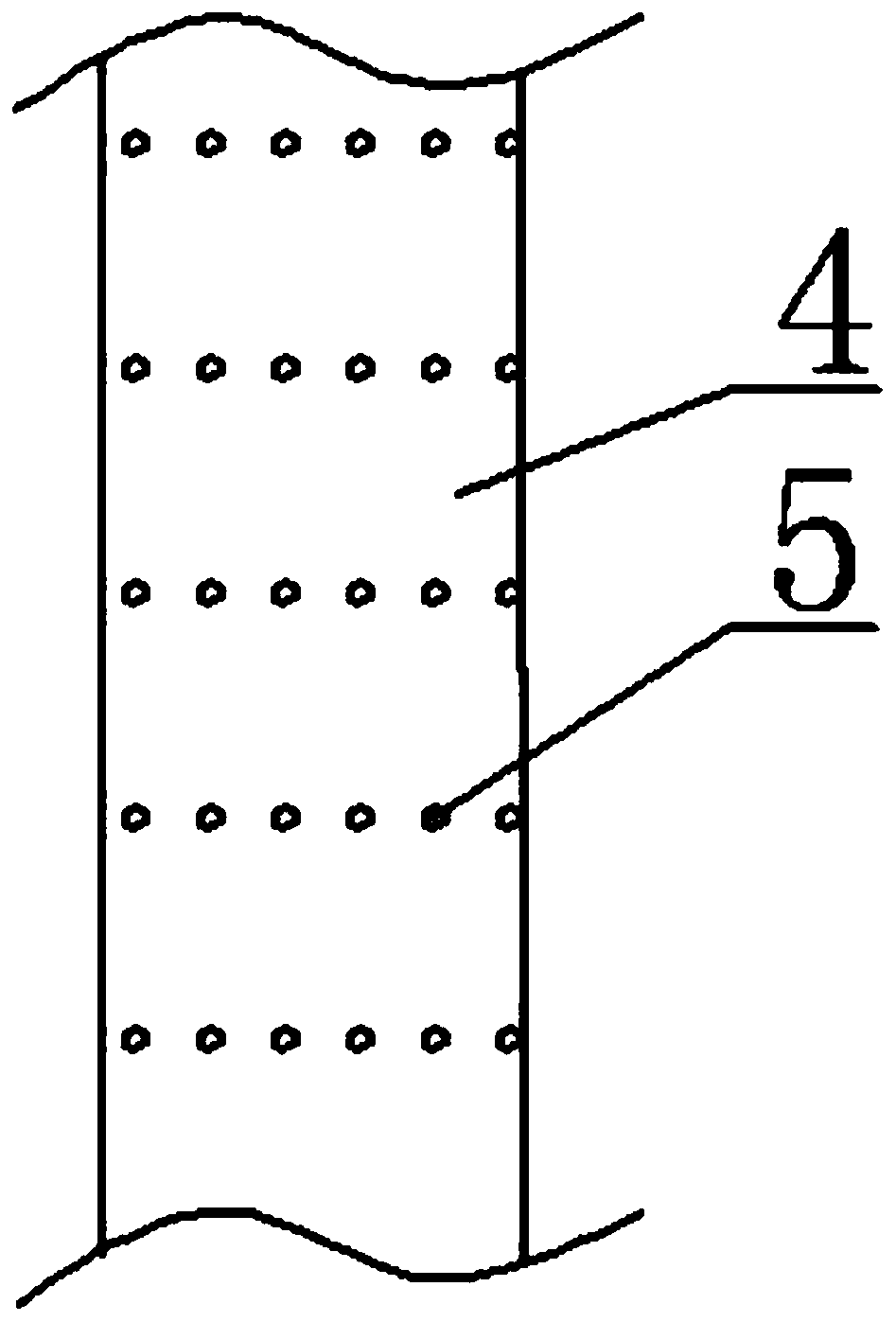

[0027] Such as Figure 1-4 As shown, a kind of anti-fouling rope includes a cable body 6, which is braided by several strands, and the outer wall of each strand 3 is sequentially provided with a nano antifouling layer and an organic Silicone anti-adhesion layer2. The nano-anti-fouling layer is set as a nano-polyethylene layer or a nano-polyurethane layer. In this embodiment, the nano-anti-fouling layer is set as a nano-polyethylene layer 1 . The thickness of the nano polyethylene layer 1 is set to 0.5 mm, and the thickness of the organosiloxane anti-adhesion layer 2 is 1 mm. The core portion of the cable body 6 is provided with a bubble generating tube 4 , and the length of the bubble generating tube 4 is greater than that of the cable body 6 . Specifically, the top of the bubble generating tube 4 protrudes from the cable body 6 for easy connection with the fan 7 . Several bubble holes 5 are arranged on the outer wall of the bubble generating tube 4, and the diameter of the...

Embodiment 2

[0029] On the basis of Example 1, different from Example 1, the outer wall of the nano-antifouling layer is also coated with a bactericidal anti-adhesion layer. The bactericidal anti-adhesion layer includes the following components in parts by weight: 10 parts of bisphenol A epoxy resin, 10 parts of magnesium oxide, 3 parts of sodium dodecylbenzenesulfonate, 2 parts of zinc oxide, and 5 parts of formaldehyde solution , 9 parts of nano silicon dioxide.

[0030] The preparation method of above-mentioned bactericidal anti-adhesion layer is:

[0031] (1) Add bisphenol A type epoxy resin to methanol solution, place it in an ultrasonic device, ultrasonicate at 70°C for 30 minutes, and dissolve it for later use;

[0032] (2) After step (1) is completed, add sodium dodecylbenzenesulfonate, emulsify and disperse for 20 minutes under mechanical stirring at 1600r / min, and obtain an emulsion for later use;

[0033] (3) Adjust the pH of the emulsion obtained in step (2) to 8, then add ma...

Embodiment 3

[0035] On the basis of Example 1, different from Example 1, the outer wall of the nano-antifouling layer is also coated with a bactericidal anti-adhesion layer. The bactericidal anti-adhesion layer includes the following components in parts by weight: 13.8 parts of bisphenol A epoxy resin, 6.2 parts of magnesium oxide, 3 parts of sodium dodecylbenzenesulfonate, 2.2 parts of zinc oxide, and 6 parts of formaldehyde solution , 9 parts of nano silicon dioxide.

[0036] The preparation method is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com