Preparation method of antibacterial cleaning paper

A clean paper and preparation system technology, applied in the field of papermaking, can solve the problems of short bacteriostatic time, poor bactericidal effect, non-targeted bactericidal, etc., and achieve the effect of reducing bacterial content, low cost, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

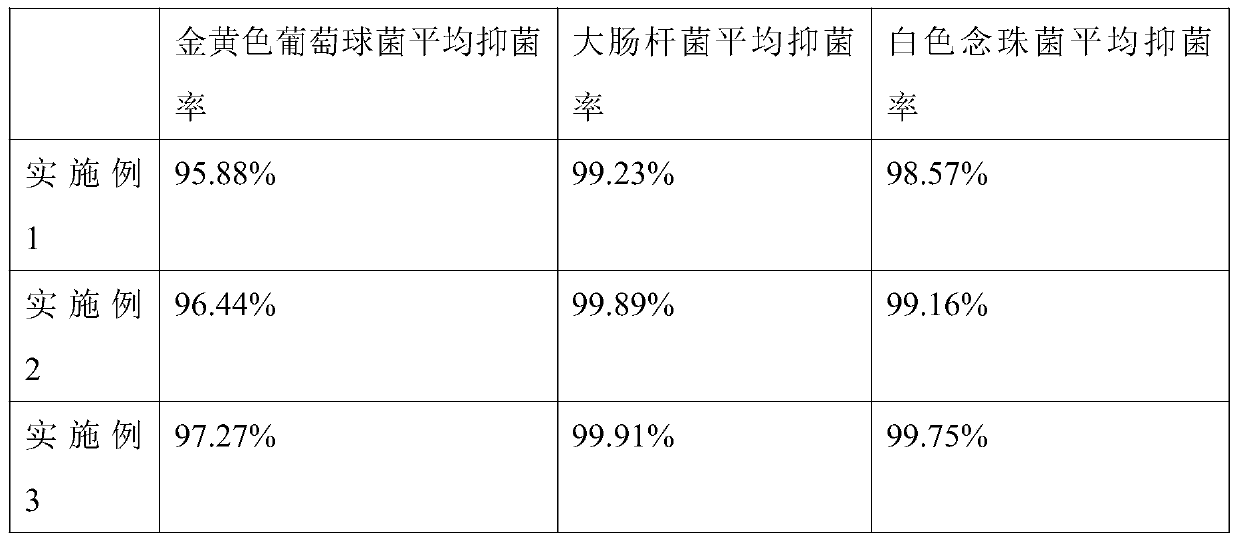

Embodiment 1

[0043] A preparation method for antibacterial cleaning paper, comprising the steps of:

[0044] 1) Preparation of sterilized pulp: add 300g of 2-methyl-3-isothiazolinone into the sterilized liquid tank, add sterilized deionized water, stir evenly for 30 minutes, and make 30ppm sterilized liquid, Automatically control the flowmeter through the control system, add it to the retention aid tank at 60ml / min, and add it to the starch tank in the paddle at 160ml / min to prepare sterilized pulp;

[0045] 2) white water sterilization: prepare ammonium sulfate solution mass fraction concentration 15%, sodium hypochlorite solution mass fraction concentration 6% respectively, by control system automatic control flowmeter, ammonium sulfate solution, sodium hypochlorite solution and deionized water are respectively mixed at 2.0l / min, Mix 5.0l / min and 180.0l / min evenly to prepare sterilized white water, add the sterilized white water to the surface layer white water bucket water chute, core l...

Embodiment 2

[0048] A preparation method for antibacterial cleaning paper, comprising the steps of:

[0049] 1) Prepare sterilized pulp: add 400g of 2-methyl-3-isothiazolinone into the sterilized liquid tank, add sterilized deionized water, stir evenly for 30 minutes, and make 40ppm sterilized liquid, Automatically control the flowmeter through the control system, add it to the retention aid tank at 40ml / min, and add it to the starch tank in the paddle at 120ml / min to prepare sterilized pulp;

[0050] 2) White water sterilization: prepare respectively 20% of ammonium sulfate solution and 7% of sodium hypochlorite solution, and automatically control the flowmeter through the control system, and use 1.5l / min, 4.0l / min, and 120l of deionized water respectively to / min Mix evenly to make sterilized white water, add the sterilized white water to the water chute of the surface layer white water bucket, the white water chute of the core layer white water bucket, the white water chute of the botto...

Embodiment 3

[0053] A preparation method for antibacterial cleaning paper, comprising the steps of:

[0054] 1) Prepare sterilized pulp: add 500g of 2-methyl-3-isothiazolinone into the sterilized liquid tank, add sterilized deionized water, stir evenly for 30 minutes, and make 50ppm sterilized liquid, Automatically control the flowmeter through the control system, add it to the retention aid tank at 20ml / min, and add it to the starch tank in the paddle at 80ml / min to prepare sterilized pulp;

[0055] 2) White water sterilization: prepare respectively 25% of ammonium sulfate solution and 10% of sodium hypochlorite solution, and automatically control the flowmeter through the control system, and use 1.0l / min, 3.0l / min, and 90l of deionized water respectively to / min Mix evenly to make sterilized white water, add the sterilized white water to the water chute of the surface layer white water bucket, the white water chute of the core layer white water bucket, the white water chute of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com