A kind of all-inorganic perovskite quantum dot multicolor luminescent film and preparation method thereof

A technology of inorganic calcium and quantum dots, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as dispersion loss, LED color drift, and inconsistent attenuation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

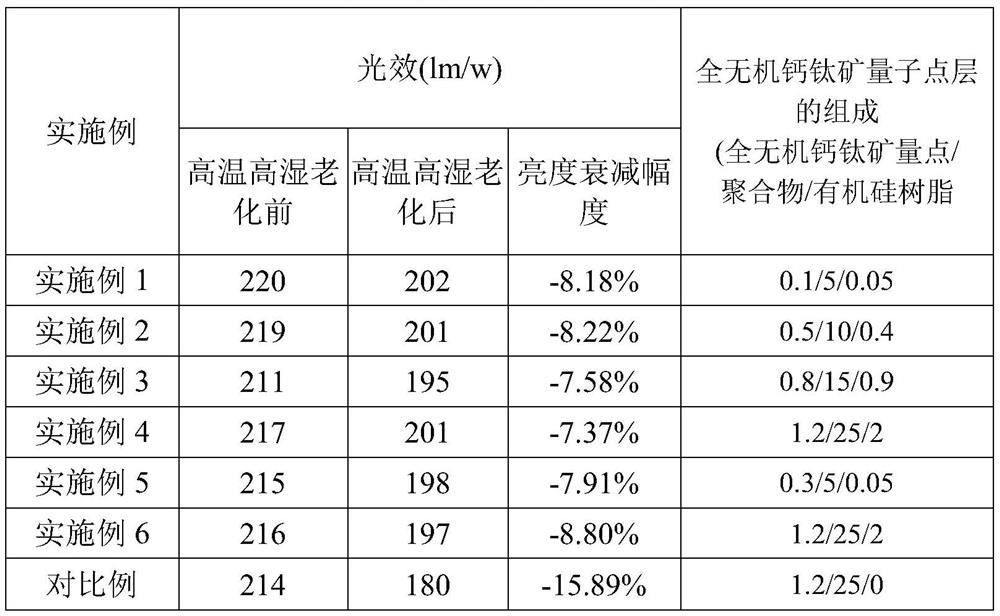

Examples

preparation example Construction

[0031] In addition, the present invention also provides a method for preparing an all-inorganic perovskite quantum dot multicolor luminescent film, which includes the following steps:

[0032] Step S1: the inorganic halide PbX 2 Mixed with CsX, completely dissolved in N,N-dimethylformamide, where X is Cl, Br or I, PbX 2 The concentration of CsX is 0.05mol / L~0.5mol / L, the concentration of CsX is 0.05mol / L~0.5mol / L, and the all-inorganic perovskite quantum dots (CsPbX 3 ) precursor solution;

[0033] Step S2: Mix the polymer and N,N-dimethylformamide evenly at a mass ratio of 1:5 to 1:25, and add a silicone resin, the amount of the silicone resin added to the mass ratio of the polymer is 0.01:1~0.08:1, stir evenly to obtain polymer solution;

[0034] Step S3: the all-inorganic perovskite quantum dot (CsPbX 3 ) precursor solution was added to the polymer solution in step S2, and stirred evenly to obtain all-inorganic perovskite quantum dots (CsPbX 3 ) coating solution;

[0...

Embodiment 1

[0038] Step S1: the inorganic halide PbBr 2Mixed with CsBr completely dissolved in the first part of N,N-dimethylformamide, PbBr 2 The concentration of CsBr is 0.05mol / L, and the concentration of CsBr is 0.05mol / L. Stir evenly to obtain all-inorganic CsPbBr 3 perovskite quantum dot precursor solution, while the inorganic halide PbI 2 Mix with CsI Dissolve completely in the second part of N,N-dimethylformamide, PbI 2 The concentration of CsPbI is 0.05mol / L, and the concentration of CsI is 0.05mol / L. Stir evenly to obtain all-inorganic CsPbI 3 Perovskite quantum dot precursor solution;

[0039] Step S2: Mix polytetrafluoroethylene (PTFE) and N,N-dimethylformamide evenly in a mass ratio of 1:5, and add polymethyl silicone resin in an amount equal to that of polytetrafluoroethylene (PTFE) The mass ratio is 0.01:1, and the polytetrafluoroethylene (PTFE) solution is obtained by stirring evenly, and two parts of polytetrafluoroethylene (PTFE) solutions are prepared simultaneously...

Embodiment 2

[0043] Step S1: the inorganic halide PbBr 2 Mixed with CsBr completely dissolved in the first part of N,N-dimethylformamide, PbBr 2 The concentration of CsPbBr is 0.1mol / L, and the concentration of CsBr is 0.1mol / L. Stir evenly to obtain all-inorganic CsPbBr 3 perovskite quantum dot precursor solution, while the inorganic halide PbI 2 Mix with CsI Dissolve completely in the second part of N,N-dimethylformamide, PbI 2 The concentration of CsPbI is 0.1mol / L, and the concentration of CsI is 0.1mol / L. Stir evenly to obtain all-inorganic CsPbI 3 Perovskite quantum dot precursor solution;

[0044] Step S2: Mix polyvinylidene fluoride (PVDF) and N,N-dimethylformamide in a mass ratio of 1:10, and add polyethyl silicone resin in an amount equal to that of polytetrafluoroethylene (PTFE) The mass ratio is 0.04:1, and the polyvinylidene fluoride (PVDF) solution is obtained by stirring evenly, and two parts of polyvinylidene fluoride (PVDF) solutions are prepared simultaneously;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com