High-grade pajamas fabric and preparation method thereof

A technology for pajamas and fabrics, applied in protective clothing, special outerwear, textiles, etc., can solve the problems of non-antibacterial and antistatic properties, unevenness, low dyeing and finishing efficiency, etc., and achieve good antistatic ability and washability , good antistatic, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

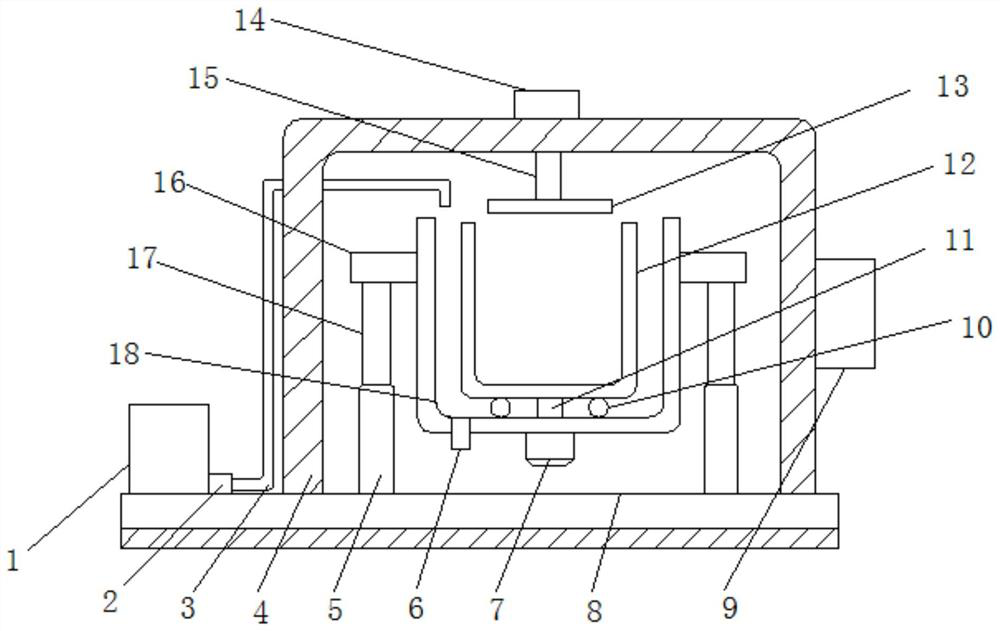

Method used

Image

Examples

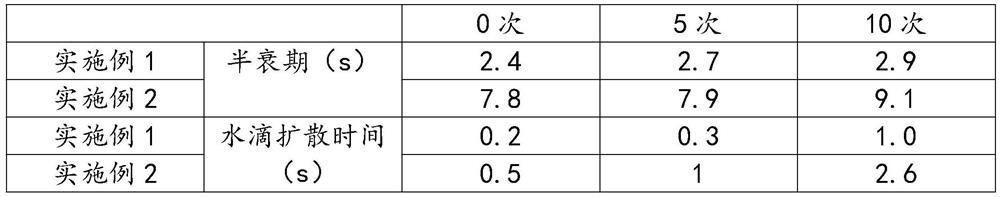

Embodiment 1

[0037] High-grade pajamas fabric, the pajamas fabric includes 35 parts of silk fiber, 60 parts of cotton fiber, 35 parts of far-infrared fiber, 1 part of modified antibacterial agent, 20-30 parts of polyethylene terephthalate 20-30 parts, modified antibacterial 1 part of electrostatic agent, 12 parts of spandex fiber, 13 parts of acrylic fiber;

[0038] The modified antibacterial agent comprises 7 parts of chitosan, 4 parts of L-arginine, 4 parts of polyethylene glycol, 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene in parts by weight. 5 parts of amine hydrochloride, 6 parts of N-hydroxy-succinimide, 5 parts of BTCA crosslinking agent;

[0039] The preparation method of described modified antibacterial agent comprises the following steps:

[0040] 1) Disperse weighed chitosan with 100mL distilled water and transfer it to a 250mL flask, then add weighed L-arginine and 1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride and N-hydroxy-succinimide, adjust the pH value...

Embodiment 2

[0053] High-grade pajamas fabric, the pajamas fabric includes 35 parts by weight of silk fiber, 60 parts of cotton fiber, 35 parts of far-infrared fiber, 1 part of modified antibacterial agent, 20-30 parts of 1.3-propylene glycol terephthalate, and 12 parts of spandex fiber 13 parts, acrylic fiber;

[0054] The modified antibacterial agent comprises 7 parts of chitosan, 4 parts of L-arginine, 4 parts of polyethylene glycol, 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene in parts by weight. 5 parts of amine hydrochloride, 6 parts of N-hydroxy-succinimide, 5 parts of BTCA crosslinking agent;

[0055] The preparation method of described modified antibacterial agent comprises the following steps:

[0056] 1) Disperse weighed chitosan with 100mL distilled water and transfer it to a 250mL flask, then add weighed L-arginine and 1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride and N-hydroxy-succinimide, adjust the pH value of the solution to 5 with 0.1mol / L hydrochlori...

Embodiment 3

[0066] High-grade pajamas fabric, the pajamas fabric includes 35 parts by weight of silk fiber, 60 parts of cotton fiber, 35 parts of far-infrared fiber, 20-30 parts of 1.3-propylene glycol terephthalate, 1 part of modified antistatic agent, spandex fiber 12 parts, 13 parts of acrylic fiber;

[0067] The modified antistatic agent comprises 30 parts by weight of terephthalic acid diester, 27 parts of isophthalic acid diester, 15 parts of 5-sodium sulfonate, 11 parts of ethylene glycol, 10 parts of polyethylene glycol, Catalyst 2 parts.

[0068] The preparation method of described modified antistatic agent comprises the following steps:

[0069] Add the weighed terephthalic acid diester, isophthalic acid diester, sodium 5-sulfonate, ethylene glycol, and polyethylene glycol into the four-necked flask in sequence, and raise the temperature to 155°C at 10°C per minute , after the reactant is completely melted, add the reaction catalyst, raise the temperature at 2°C per minute to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com