High CTI high impact flame retardant reinforced PA6/PBT material and preparation method thereof

A high-impact, composite flame-retardant technology, applied in the field of polymer materials, can solve the problems of poor comprehensive mechanical properties of halogen-free flame-retardant reinforced alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

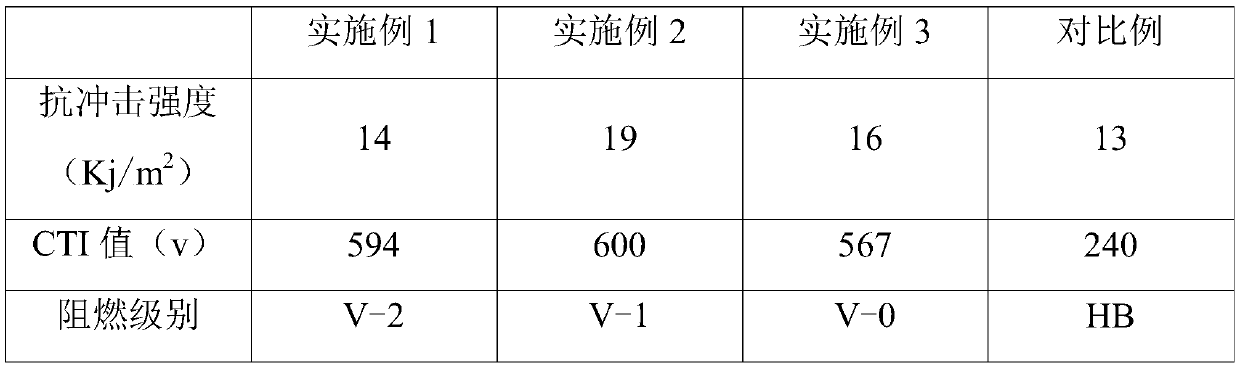

Examples

Embodiment 1

[0030] This embodiment provides a high-CTI high-impact flame-retardant reinforced PA6 / PBT material. The preparation raw materials are calculated in parts by mass and include the following components: 20 parts of PA6, 45 parts of PBT, 15 parts of glass fiber, composite resistance 10 parts of combustion masterbatch, 1 part of compatible toughening agent, 0.2 part of antioxidant, 0.2 part of lubricant.

[0031] This embodiment also provides a method for preparing a high-CTI, high-impact, flame-retardant reinforced PA6 / PBT material, which specifically includes the following steps:

[0032] S1: Pre-mixing of raw materials: According to the proportion of the above raw materials, take 20 parts of PA6, 45 parts of PBT and 1 part of compatible toughening agent after drying, and combine them with 0.2 parts of antioxidant and 0.2 parts of lubricant Put it in a high-speed mixer, mix well at room temperature to obtain the mixture, and reserve;

[0033] S2: Modification of glass fiber:

[0034] (1...

Embodiment 2

[0039] This embodiment provides a high-CTI high-impact flame-retardant reinforced PA6 / PBT material. The preparation raw materials are calculated in parts by mass and include the following components: 30 parts of PA6, 20 parts of PBT, 30 parts of glass fiber, composite resistance 15 parts of combustible masterbatch, 3 parts of compatible toughening agent, 0.8 part of antioxidant, 1.2 parts of lubricant.

[0040] This embodiment also provides a method for preparing a high-CTI, high-impact, flame-retardant reinforced PA6 / PBT material, which specifically includes the following steps:

[0041] S1: Pre-mixing of raw materials: According to the proportion of the above raw materials, take 30 parts of PA6, 20 parts of PBT and 3 parts of compatible toughening agent after drying, and combine them with 0.8 parts of antioxidant and 1.2 parts of lubricant Put it in a high-speed mixer, mix well at room temperature to obtain the mixture, and reserve;

[0042] S2: Modification of glass fiber:

[0043...

Embodiment 3

[0048] This embodiment provides a high-CTI high-impact flame-retardant reinforced PA6 / PBT material. The preparation raw materials are calculated in parts by mass and include the following components: 40 parts of PA6, 10 parts of PBT, 30 parts of glass fiber, composite resistance 20 parts combustion masterbatch, 5 parts compatible toughening agent, 1.5 parts antioxidant, 2.0 parts lubricant.

[0049] This embodiment also provides a method for preparing a high-CTI, high-impact, flame-retardant reinforced PA6 / PBT material, which specifically includes the following steps:

[0050] S1: Pre-mixing of raw materials: According to the proportion of the above raw materials, take 40 parts of PA6, 10 parts of PBT and 5 parts of compatible toughening agent after drying, and combine them with 1.5 parts of antioxidant and 2.0 parts of lubricant Put it in a high-speed mixer, mix well at room temperature to obtain the mixture, and reserve;

[0051] S2: Modification of glass fiber:

[0052] (1) Put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com