Particle and preparation method thereof

A particle and surface ligand technology, applied in the field of quantum dots, can solve problems such as large differences in coordination ability, inability to finely adjust the degree of coordination, and limited selection of functional groups, so as to enhance coordination ability and ensure sufficient passivation , Improve the effect of luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] The preparation of the present embodiment CdSe / ZnS quantum dots comprises the following steps:

[0111] 1) Add 0.8mmol cadmium oxide, 8mmol zinc acetate, 10mL oleylamine and 30mL octadecene into a 100mL three-necked flask, and exhaust at 170°C for 30 minutes to remove water and oxygen in the reaction system;

[0112] 2), after the reaction system is filled with argon, the temperature is raised to 300 degrees;

[0113] 3) Rapidly inject a mixed reaction solution of 0.2 mmol of elemental selenium, 8 mmol of elemental sulfur and 4 mL of trioctylphosphine into the reaction system, and react at 300 degrees for 10 minutes to obtain CdSe / ZnS quantum dots.

[0114] The luminescence wavelength of the obtained CdSe / ZnS quantum dots in n-hexane solvent is 525 nanometers, the peak width is 25 nanometers, and the yield of quantum dots is 53%.

Embodiment I

[0116] The preparation of InP / ZnSeS quantum dots in this embodiment comprises the following steps:

[0117] 1) Add 0.16mmol indium chloride, 1mL tetrahydrofuran, 0.5mL oleic acid and 8mL octadecene into a 50mL three-necked flask, and exhaust at 150 degrees for 30 minutes to remove water and oxygen in the reaction system;

[0118] 2), after the reaction system is filled with argon, the temperature is raised to 280 degrees;

[0119] 3) Quickly inject 0.06mmol P(TMS) into the reaction system 3 (Tri-trimethylsilylphosphorus), a mixed solution of 0.5mL octadecene, and react at 280 degrees for 20 seconds to obtain the InP quantum dot core;

[0120] 4), inject 0.04mmol Se-TOP precursor, 1.2mmol dodecyl mercaptan, 2mmol zinc oleate into the reaction system at a uniform speed within 30 minutes;

[0121] 5) After the reaction, the temperature is naturally lowered to obtain InP / ZnSeS quantum dots.

[0122] The luminescence wavelength of the obtained InP / ZnSeS quantum dots in n-hexane ...

Embodiment 3

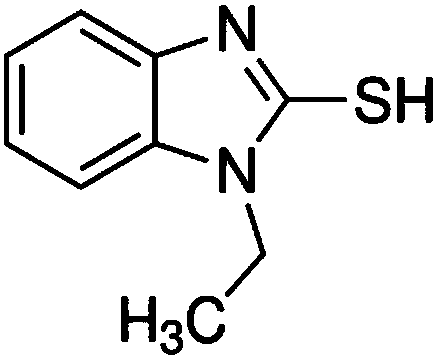

[0124] This embodiment takes figure 1 Structural molecules are used as surface ligands, and the particles of this embodiment (the particles are composed of: CdSe / ZnS quantum dots and the CdSe / ZnS quantum dot surface combined figure 1 The preparation of structure molecule) comprises the following steps:

[0125] 1), weigh 400 mg of CdSe / ZnS quantum dots in the above-mentioned embodiment 1 and add them into 20 mL of octadecene to fully dissolve to obtain a CdSe / ZnS quantum dot solution;

[0126] 2), add 0.5mL surface ligand to the above CdSe / ZnS quantum dot solution at one time;

[0127] 3), the mixed system was heated up to 120 degrees Celsius, and reacted for 60 minutes under a nitrogen atmosphere;

[0128] 4) After cooling the reaction system to room temperature, the particles are obtained by centrifugal separation and washing.

[0129] The yield of the particles was 62%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

| Peak width | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com