Lactococcus lactis ZF625 and application thereof

A technology of Lactococcus lactis, which is used in the field of microbial application and vinegar brewing, can solve the problems of poor flavor, lack of full-bodied feeling, and strong sour taste stimulation, and achieve the effect of increasing lactic acid content, enhancing full-bodied feeling, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

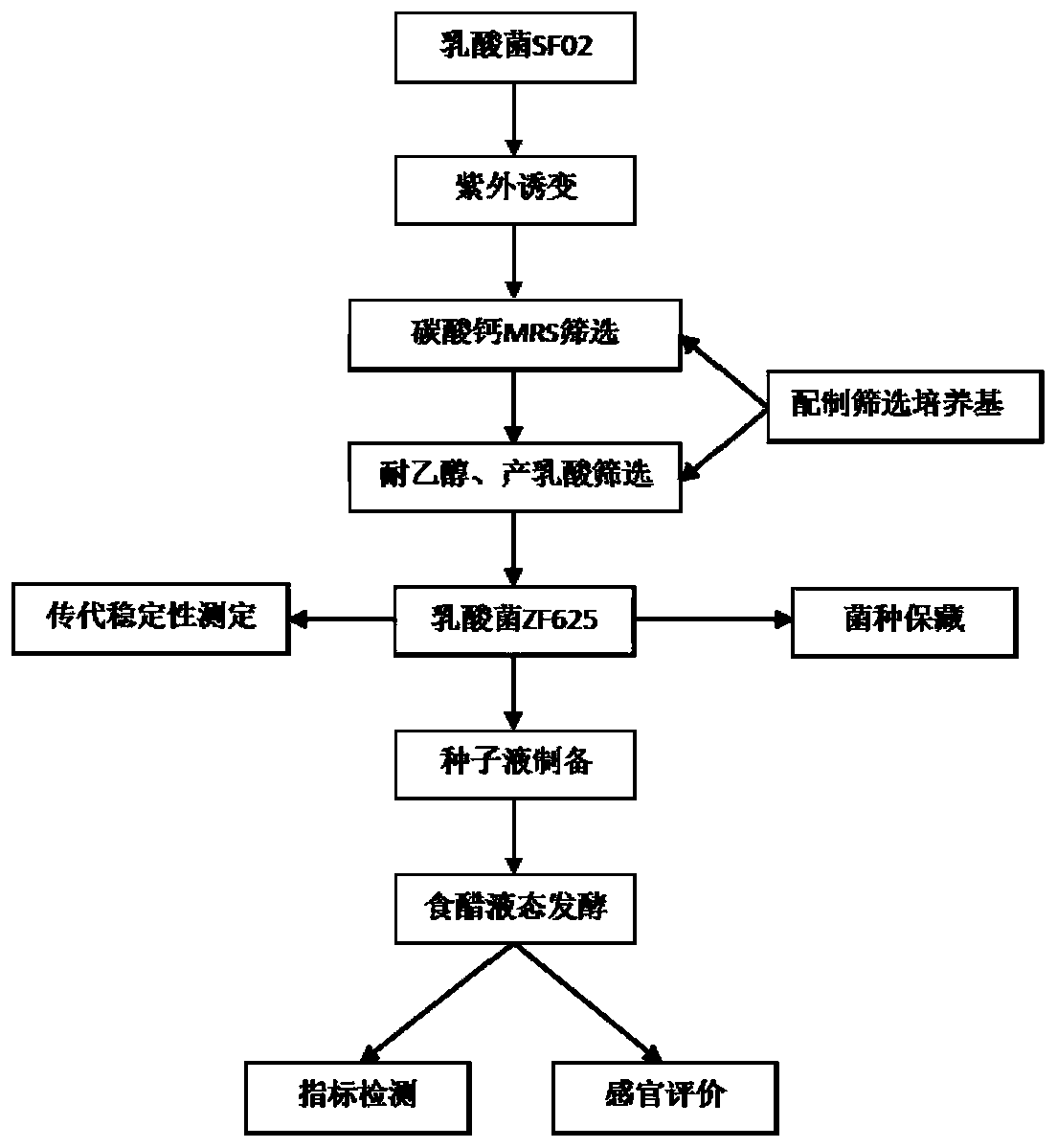

[0032] Embodiment 1 strain mutagenesis and screening

[0033] (1) strain mutagenesis

[0034] Lactococcus lactis SF02 was used as the starting strain, cultured with MRS medium, and the bacterial liquid was taken in the logarithmic growth phase for ultraviolet mutagenesis. Dilute the bacterial solution to 10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 Concentration, made of cell dilution.

[0035] (2) Strain screening

[0036]Take 0.2mL of the appropriate dilution of bacterial cell dilution and spread it on the MRS medium plate containing calcium carbonate, culture anaerobically at 37°C for 48 hours, and select the colony whose diameter of the calcium soluble circle is significantly larger than the starting strain as the primary screening strain, repeat Purified by streaking twice, preliminary screening obtained 26 strains of Lactococcus lactis with better acid production ability, the larger the diameter of the calcium soluble circle, the better the acid production ability of...

Embodiment 2

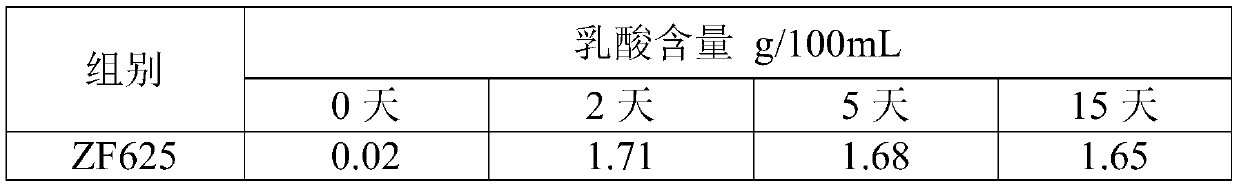

[0044] Embodiment 2 passage stability test

[0045] Lactococcus lactis ZF625 obtained in Example 1 was inoculated onto MRS slant medium for 10 generations, and the subculture conditions were: anaerobic culture at 37°C for 48 hours, and the growth of each generation of strains was observed and recorded. The first generation, The 5th and 10th generation subcultured strains were inoculated into the MRS medium containing 8% vol ethanol and cultured for 72 hours according to the method described in Example 1, and then the lactic acid content was measured. The results are shown in Table 2.

[0046] Table 2 Passage stability of Lactococcus lactis ZF625

[0047] Test items

[0048] The results in Table 2 show that the strains of each generation were inoculated in the MRS medium containing 8% vol ethanol, and the lactic acid content error between the first generation, the fifth generation, and the tenth generation was within the error range of 10%, indicating that Lactococcus...

Embodiment 3

[0049] Embodiment 3 vinegar liquid state fermentation

[0050] (1) Preparation of seed solution

[0051] Preparation of primary seed solution: Inoculate Lactococcus lactis ZF625 obtained in Example 1 into MRS medium at an inoculum amount of 5% by volume, and culture at 37° C. for 20 h.

[0052] Preparation of the secondary seed solution: Inoculate the primary seed solution into the MRS medium containing 8% Vol ethanol according to the inoculum amount of 5% volume ratio, and incubate at 37° C. for 20 h.

[0053] (2) Liquid fermentation

[0054] Weigh 10kg of rice flour, add 30L of water, heat and boil for high-temperature gelatinization after stirring, then cool down to 60-75°C, add amylase to liquefy for 15-30min, control the temperature at 45-60°C, add glucoamylase, stir and saccharify for 30 minutes After ~45min, put it into a 50L liquid fermenter, control the temperature at 28-32°C, add yeast for alcoholic fermentation, and after 24 hours, add the secondary seed liquid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com