Nickel-base aluminum oxide high-temperature self-lubricating wear-resistant coating and preparation method thereof

A high-temperature self-lubricating, wear-resistant coating technology, applied in the field of wear-resistant coatings, can solve problems such as poor high-temperature lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

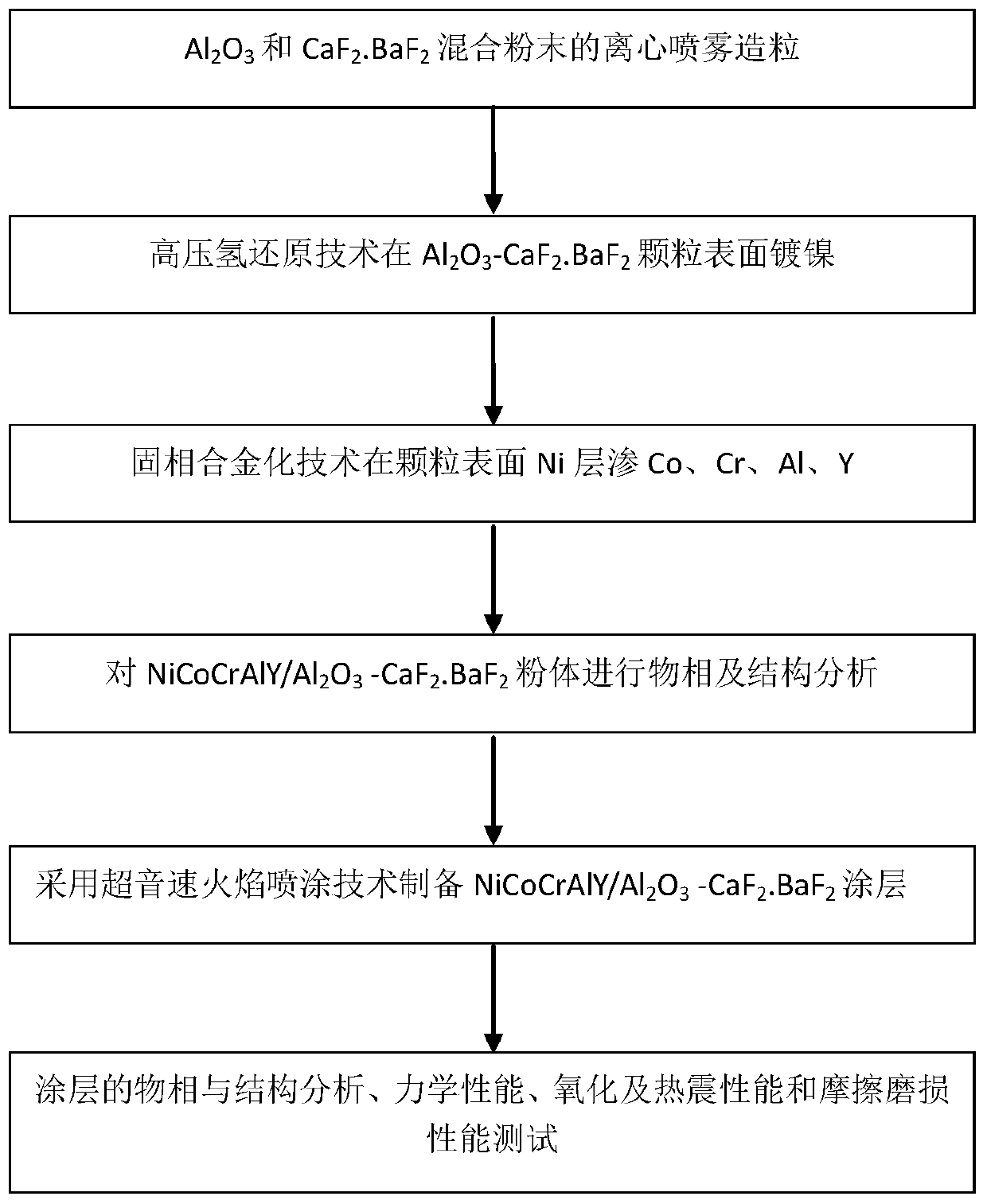

[0022] 1. Preparation of powder

[0023](1) Weigh Al respectively according to the stoichiometric ratio 2 o 3 and CaF 2 .BaF 2 Put the powder into a plastic bucket, add a certain proportion of deionized water, mix it evenly with a JJ-1 booster electric mixer, add an appropriate amount of defoamer to remove the air bubbles in the mixed slurry, and spray it through LGZ high-speed centrifugal spray The granulation dryer performs centrifugal spray granulation on the mixed slurry to obtain spherical Al 2 o 3 -CaF 2 .BaF 2 Composite powder.

[0024] The weight composition of each component is: Ni: Co: Cr: Al: Y = 74: 2.5: 17.5: 5.5: 0.5; NiCoCrAlY: 40% ~ 50%; Al 2 o 3 : 40%~50%; CaF 2 .BaF 2 : 5% to 15%. where CaF 2 .BaF 2 for CaF 2 and BaF 2 The mixed powder, the molar ratio between the two is 1:1.

[0025] (2) Sieve the prepared composite powder, and take particles between 20-45 μm for subsequent preparation of supersonic composite powder.

[0026] (3) First, tak...

Embodiment 1

[0032] NiCoCrAlY / Al 2 o 3 -CaF 2 .BaF 2 Composite coating, its composition is: Ni:Co:Cr:Al:Y=74:2.5:17.5:5.5:0.5; NiCoCrAlY: 50%; Al 2 o 3 : 40%; CaF 2 .BaF 2 : 10%. Al was prepared by spray granulation technique 2 o 3 -CaF 2 .BaF 2 composite powder, and prepared coated NiCoCrAlY / Al by high-pressure hydrogen reduction technology and solid phase alloying technology 2 o 3 -CaF 2 .BaF 2 Composite powder, NiCoCrAlY / Al was prepared by supersonic flame spraying technology 2 o 3 -CaF 2 .BaF 2 Composite coating material, testing its coefficient of friction and wear rate.

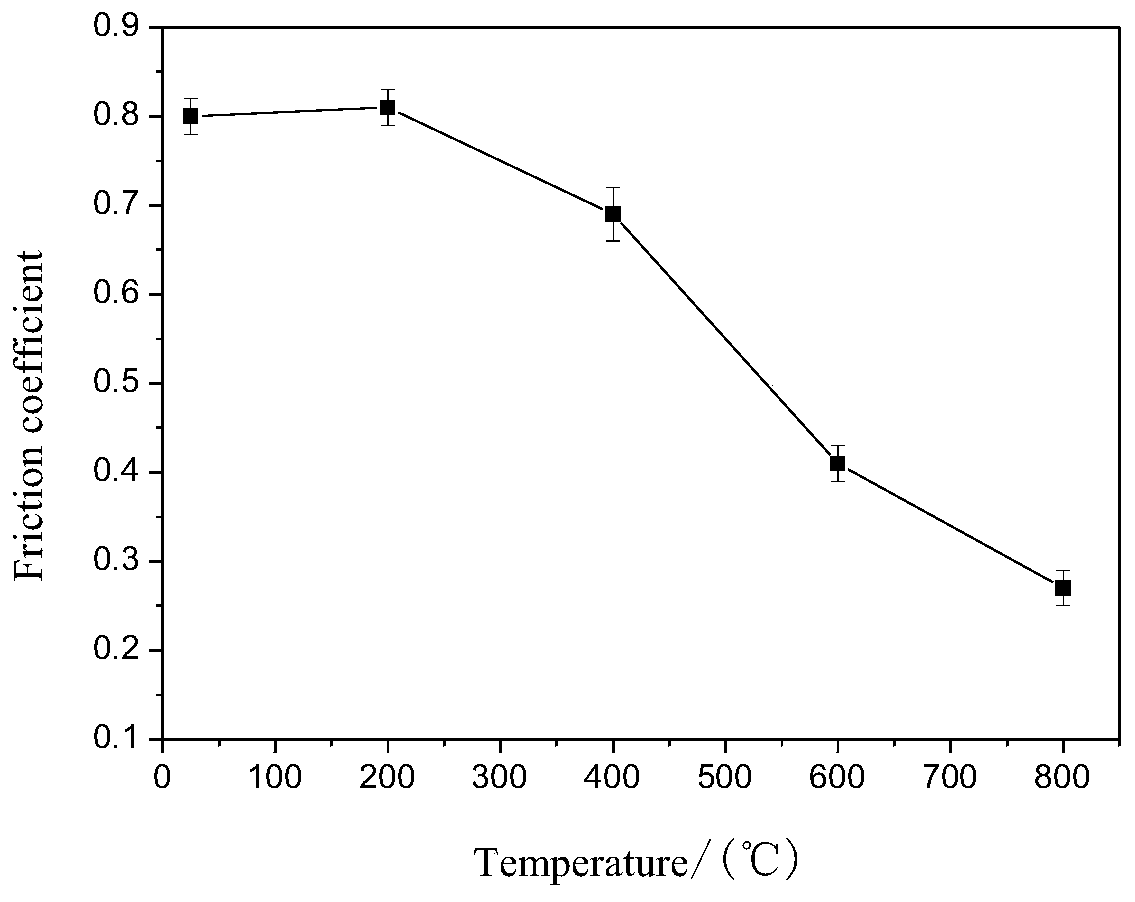

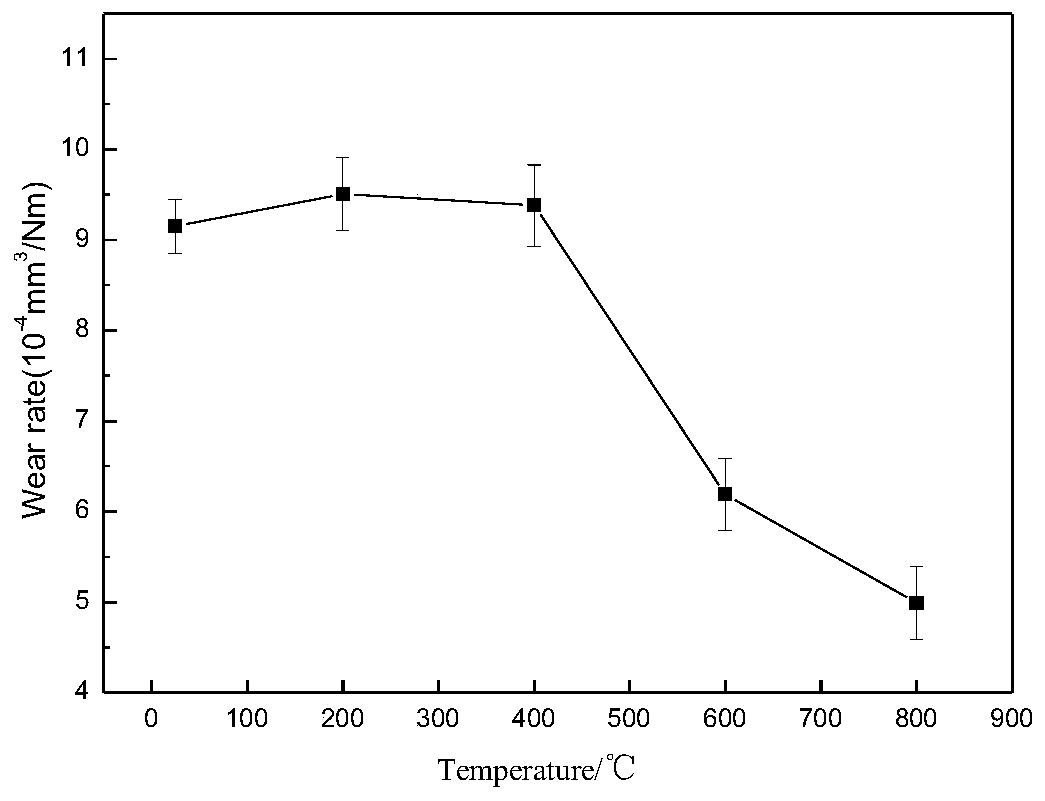

[0033] figure 2 Shown is the temperature vs. HVOF NiCoCrAlY / Al 2 o 3 -CaF 2 .BaF 2 Effect of composite coating on coefficient of friction. As shown in the figure, as the temperature increases, the friction coefficient of the coating first increases slightly and then decreases. At 200°C, the friction coefficient is the largest at about 0.81, and at 800°C, the friction coefficient is the small...

Embodiment 2

[0037] NiCoCrAlY / Al 2 o 3 Composite coating, its composition is: Ni:Co:Cr:Al:Y=74:2.5:17.5:5.5:0.5; NiCoCrAlY: 45%; Al 2 o 3 : 50%; CaF 2 .BaF 2 : 5%. Al was prepared by spray granulation technique 2 o 3 powder, and the coated NiCoCrAlY / Al was prepared by high-pressure hydrogen reduction technology and solid phase alloying technology 2 o 3 Composite powder, NiCoCrAlY / Al was prepared by supersonic flame spraying technology 2 o 3 Composite coating material, testing its coefficient of friction and wear rate.

[0038] Conclusion: The lowest wear rate at room temperature is 4.8×10 -4 mm 3 / Nm. At 800°C, the friction coefficient is the lowest, about 0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com