Non-aqueous electrolyte and lithium ion battery

A non-aqueous electrolyte, lithium-ion battery technology, used in secondary batteries, secondary battery repair/maintenance, circuits, etc., to achieve the effects of improving cycle performance, reducing flammability, and suppressing flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

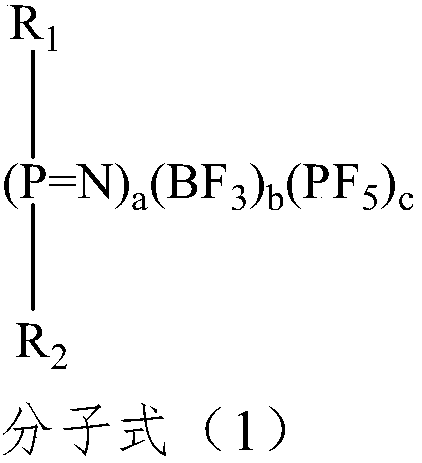

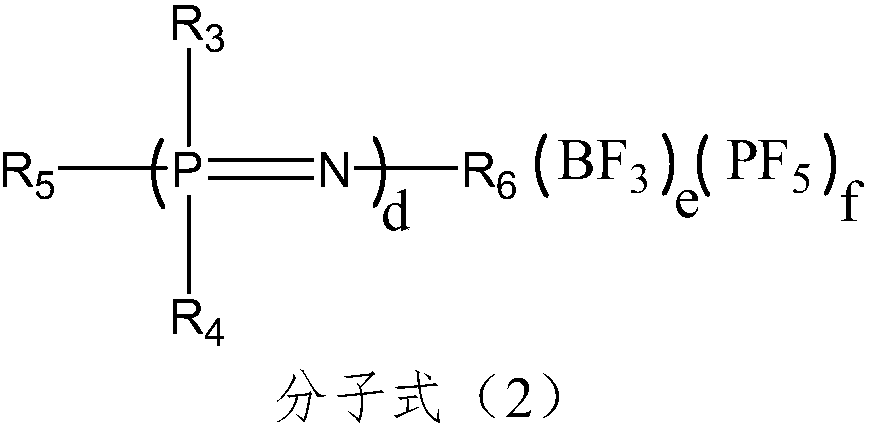

Method used

Image

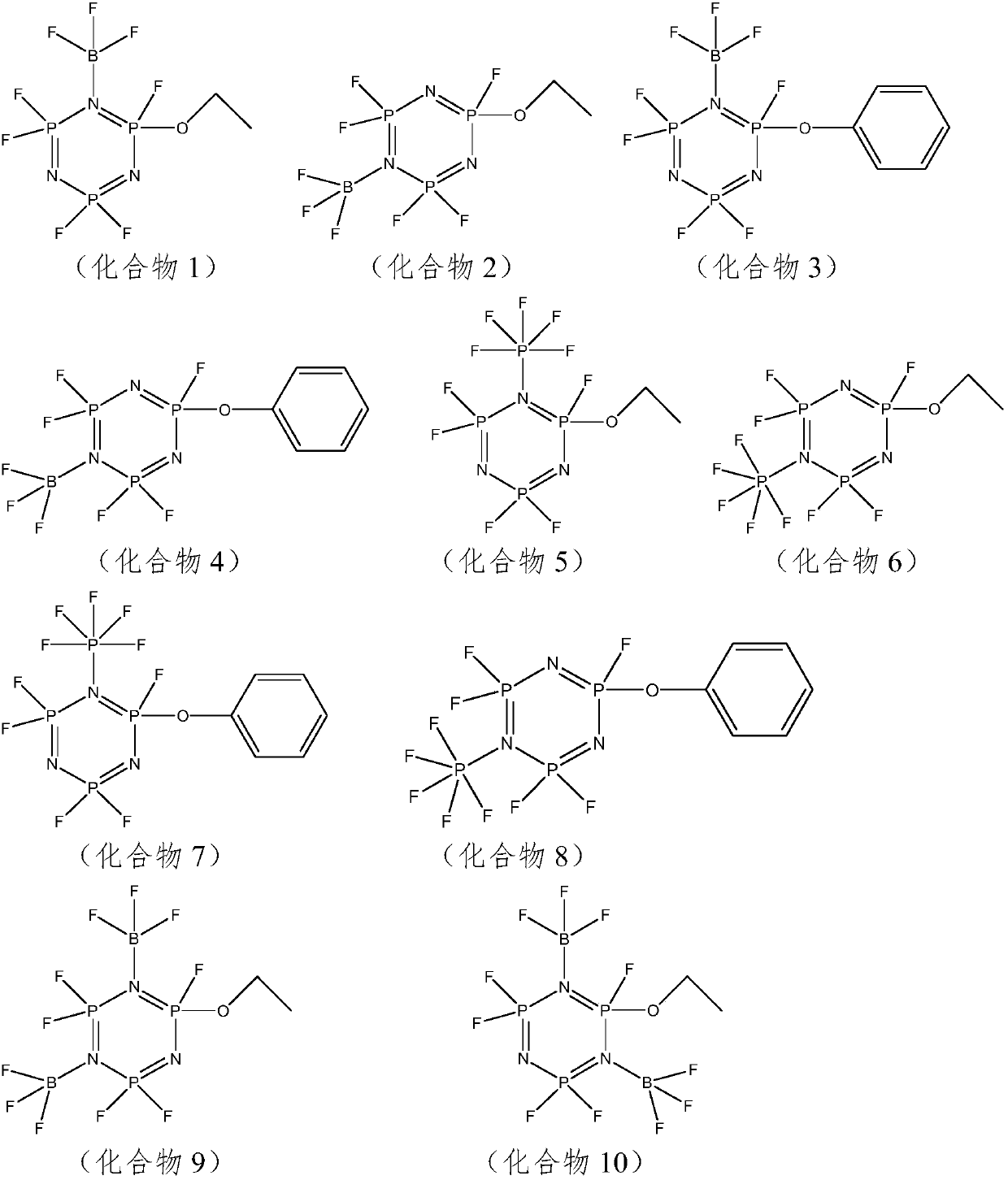

Examples

Embodiment 1

[0070] This embodiment is used to illustrate a kind of non-aqueous electrolytic solution disclosed by the present invention, lithium ion battery and its preparation method, comprising the following steps:

[0071] The positive electrode preparation step is: mix the positive electrode active material LiNi according to the mass ratio of 95:3:2 0.8 mn 0.1 co 0.1 o 2 , conductive carbon black and binder polyvinylidene fluoride are dispersed in N-methyl-2-pyrrolidone to obtain positive electrode slurry, and the positive electrode slurry is evenly coated on both sides of the aluminum foil, after drying, calendering and Vacuum drying, and welding aluminum lead wires with an ultrasonic welder to obtain a positive plate, the thickness of the positive plate is between 120-150 μm.

[0072] Negative electrode preparation steps are: mix graphite, conductive carbon black, binder styrene-butadiene rubber and carboxymethyl cellulose according to the mass ratio of 94:1:2.5:2.5, disperse in ...

Embodiment 2

[0078] This embodiment is used to illustrate a kind of non-aqueous electrolytic solution disclosed by the present invention, lithium ion battery and its preparation method, including most of the operation steps in embodiment 1, and its difference is:

[0079] In the electrolyte, 1% of the compound 32 is used to replace 1% of the compound 31 based on the total mass of the electrolyte.

Embodiment 3

[0081] This embodiment is used to illustrate a kind of non-aqueous electrolytic solution disclosed by the present invention, lithium ion battery and its preparation method, including most of the operation steps in embodiment 1, and its difference is:

[0082] In the electrolyte, 1% of compound 31 by the total mass of the electrolyte is replaced by 1% of the compound 33 by the total mass of the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com