Preparation method of silk fibroin microsphere drug sustained-release carrier and application thereof

A technology of silk fibroin microspheres and slow-release carriers, which is applied in the fields of botanical equipment and methods, biochemical equipment and methods, and applications, can solve the problems of inability to take into account the fast initial release speed and slow release of drugs, and achieve excellent Slow release effect, good application prospect, excellent biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a preparation method of a silk fibroin microsphere drug slow-release carrier, comprising the following steps:

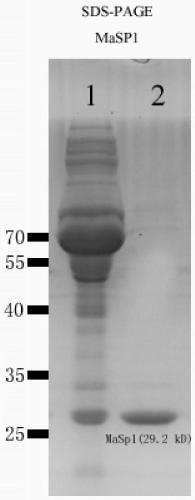

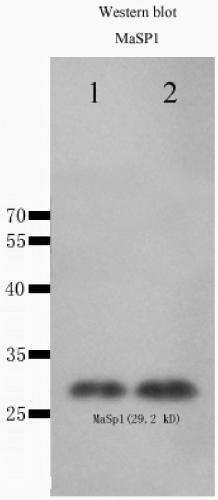

[0036] 1) Dissolve the recombinant spidroin fiber with deionized water and ethanol, after dissolving, filter through gauze and place it in a dialysis bag with a molecular weight cut-off of 8-10kD for dialysis for 4 days, filter and concentrate to obtain a silk fibroin solution with a concentration of 0.8wt% ;

[0037]2) The silk fibroin solution obtained in step 1) is placed in a dialysis bag (the molecular weight cut-off of the dialysis bag is 8-10kD), and nanomaterials are added into the dialysis bag (the nanomaterials are nano titanium dioxide particles and nano sheep bone particles, The mass ratio of the nano-material to the silk fibroin solution is 0.1:100, the mass ratio of the nano-titanium dioxide particles to the nano-sheep bone particles is 0.3:1, and the particle diameter of the nano-titanium dioxide particles is 30-50nm, T...

Embodiment 2

[0041] This embodiment provides a preparation method of a silk fibroin microsphere drug slow-release carrier, comprising the following steps:

[0042] 1) Dissolve the recombinant spidroin fiber with deionized water and ethanol, after dissolving, filter through gauze and place it in a dialysis bag with a molecular weight cut-off of 8-10kD for dialysis for 4 days, filter and concentrate to obtain a silk fibroin solution with a concentration of 1.0wt% ;

[0043] 2) The silk fibroin solution obtained in step 1) is placed in a dialysis bag (the molecular weight cut-off of the dialysis bag is 8-10kD), and nanomaterials are added into the dialysis bag (the nanomaterials are nano titanium dioxide particles and nano sheep bone particles, The mass ratio of the nano-material to the silk fibroin solution is 0.3:100, the mass ratio of the nano-titanium dioxide particles to the nano-sheep bone particles is 0.5:1, and the particle diameter of the nano-titanium dioxide particles is 30-50nm, ...

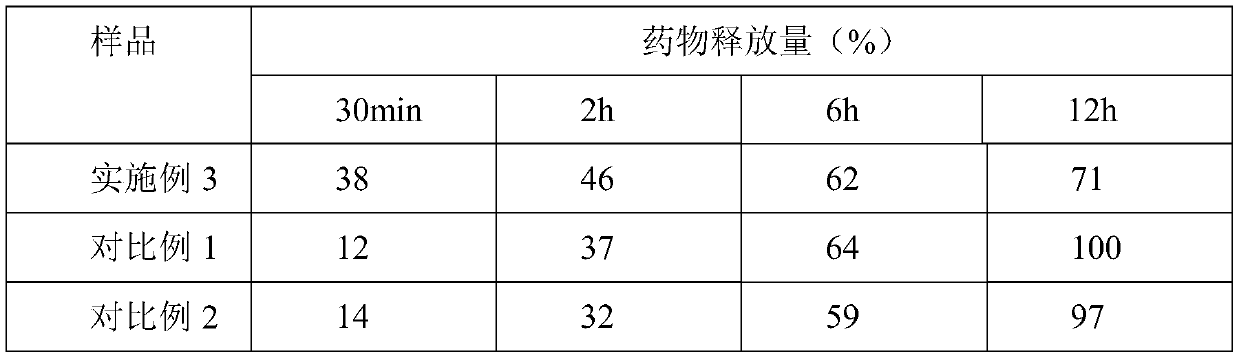

Embodiment 3

[0047] This embodiment provides a preparation method of a silk fibroin microsphere drug slow-release carrier, comprising the following steps:

[0048] 1) Dissolve the recombinant spidroin fiber with deionized water and ethanol, after dissolving, filter through gauze and place it in a dialysis bag with a molecular weight cut-off of 8-10kD for dialysis for 3 days, filter and concentrate to obtain a silk fibroin solution with a concentration of 0.9wt% ;

[0049] 2) The silk fibroin solution obtained in step 1) is placed in a dialysis bag (the molecular weight cut-off of the dialysis bag is 8-10kD), and nanomaterials are added into the dialysis bag (the nanomaterials are nano titanium dioxide particles and nano sheep bone particles, The mass ratio of the nano-material to the silk fibroin solution is 0.2:100, the mass ratio of the nano-titanium dioxide particles to the nano-sheep bone particles is 0.4:1, and the particle diameter of the nano-titanium dioxide particles is 30-50nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com